11

CAUTION

Low flue gas temperature increases the risk of

condensation. Adjust the total temperature at or higher

then 204°C (400°F) in order for the heat exchanger

warranty to remain in force.

3.3.5

Overfire pressure test

The overfire draft that is taken through the observation port,

located above the burner, is a measurement necessary to

determine if there is a blockage in the heat exchanger or the

flue pipe. Refer to the Technical Specifications in this manual

for overfire pressure values. A high pressure condition may be

caused by excessive combustion air, due to the air band being

too wide open, or a lack of flue draft (chimney effect) or some

other blockage, such as soot in the secondary section of the

heat exchanger or the use of an oversize nozzle input or high

pressure pump.

3.3.6 Vent Temperature Test

1.

After having adjusted the burner combustion, insert a

thermometer into the test hole in the breech pipe;

2.

The total vent temperature should be between 204 and

302°C (400 and 575°F). If not, check for improper air

temperature rise, pump pressure, nozzle size or a badly

sooted heat exchanger.

3.3.7 Supply Air Temperature Rise Test

1.

Operate the burner for at least 10 minutes;

2.

Measure the air temperature in the return air plenum;

3.

Measure the air temperature in the supply duct just

outside the range of radiant heat from the heat

exchanger. 0.3 m (12") from the plenum of the main take-

off is usually sufficient;

4.

The temperature rise is calculated by subtracting the

return air temperature from the supply air temperature;

5.

If the temperature rise is lower or exceeds the

temperature specified in Table 6, change to the next

lower or higher blower speed tap, until the temperature

rise falls to the target. If the excessive temperature rise

cannot be increased or reduced by changing fan speed,

investigate for ductwork obstructions, dirty or improper air

filter, improper firing caused by improper pump pressure

or nozzle sizing.

3.3.8 Limit Control Check

After operating the furnace for at least 15 minutes, restrict the

return air supply by blocking the filters or the return air register

and allow the furnace to shut off on High Limit. The burner will

shut off but the blower will continue to run.

Remove the obstruction and the burner should restart after a

few minutes. The time required for the restart also depends on

the adjustment of the blower “OFF” delay.

3.3.9 Restart after Burner Failure

1.

Set the thermostat lower than room temperature;

2.

Press the reset button on the burner primary control

(relay);

3.

Set the thermostat higher than room temperature;

4.

If the burner motor does not start or ignition fails, turn

off the disconnect switch and CALL A QUALIFIED

SERVICE TECHNICIAN.

CAUTION

Do not attempt to start the burner when excess oil has

accumulated, when the furnace is full of vapour or when

the combustion chamber is hot.

Summary of Contents for AMP154SD

Page 17: ...17 Figure 9 Furnace Dimensions ...

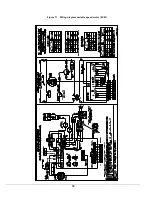

Page 18: ...18 Figure 10 Wiring diagram 4 speed motor PSC ...

Page 19: ...19 Figure 11 Wiring diagram variable speed motor ECM ...

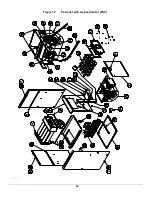

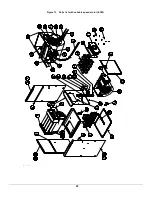

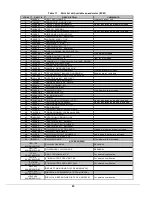

Page 20: ...20 Figure 12 Parts list with 4 speed motor PSC B500111A ...

Page 22: ...22 Figure 13 Parts list with variable speed motor ECM B50112A ...