12

4

MAINTENANCE

WARNING

Electrical shock hazard.

Turn OFF power and fuel to the furnace before any

disassembly or servicing.

Failure to do so can result in death, bodily injury and/or

property damage.

Preventive maintenance is the best way to avoid unnecessary

expense and inconvenience. Have your heating system and

burner inspected by a qualified service technician at regular

intervals.

To maintain the reliability and optimal performance of the

furnace, have a complete combustion check done after the

annual maintenance call. Do not attempt to repair the furnace

or its controls. Call a qualified service technician.

Before calling for repair service check the following

points:

1. Check the oil tank gauge and make sure that the valve is

open;

2. Check fuses and the circuit breaker;

3. Check if the main disconnect switch is ON ;

4. Set the thermostat above room temperature;

5. If ignition does not occur, turn off the disconnect switch

and call a qualified service technician.

When ordering replacement parts, please specify the

complete furnace model number and serial number.

4.1 CLEANING

THE

HEAT

EXCHANGER

It is not generally necessary to clean the heat exchanger or

flue pipe every year, but it is advisable to have the oil burner

service technician check the unit before each heating season

to determine whether the cleaning or replacement of parts is

necessary.

If a cleaning is necessary, the following steps should be

performed:

1. Turn OFF all utilities upstream from the furnace;

2. Disconnect the flue pipe;

3. Remove the flue collar panel located at the front of the

furnace;

4. Remove the heat exchanger baffles;

5. Disconnect the oil line and remove the oil burner;

6. Clean the secondary tubes and the primary cylinder with

a stiff brush and a vacuum cleaner;

7. Before re-assembling the unit, the heat exchanger and

combustion chamber should be inspected to determine if

replacement is required;

8. After the cleaning, replace the heat exchanger baffles,

flue collar plate and oil burner;

9. Readjust the burner for proper operation.

4.2 CLEANING

THE

BLOCKED

VENT

SHUT-OFF

DEVICE

(BVSO)

For continuous safe operation, the Blocked Vent Shut-off

device (BVSO) must be inspected and maintained annually

by a qualified service technician.

1. Disconnect power to the appliance;

2. Remove the two screws holding on the BVSO

assembly cover;

3. Remove the cover;

4. Remove the two screws holding the control box to the

heat transfer tube assembly. Sliding the control box in

the appropriate direction will unlock it from the heat

transfer tube assembly;

5. Carefully remove any build-up from the thermal switch

surface;

CAUTION

Do not dent or scratch the surface of the thermal switch. If

the thermal switch is damaged it MUST be replaced.

6. Clean and remove any build-up or obstruction inside

the heat transfer tube;

7. Re-mount, lock and fasten the control box with the 2

screws removed in step 4;

8. Re-attach the assembly cover with the screws

removed in step 2;

9. Re-establish power to the unit.

4.3 CLEANING

THE

BURNER

HEAD

Once annually, remove the retention head and electrodes

from the drawer assembly and remove all foreign matter,

if necessary. Also clean the extremity of the burner tube,

if necessary.

4.4 CHANGING

THE

NOZZLE

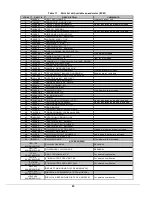

Change the nozzle once a year with the one specified in

table 6.

4.5 CHANGING

THE

OIL

FILTER

Tank Filter

The tank filter should be changed as required. Follow the

manufacturer’s instructions.

Secondary Filter

The 10 micron, or finer, filter cartridge should be changed

annually. Follow the manufacturer’s instructions.

4.6 CHANGING

THE

AIR

FILTER

Dirty filters have an impact on the efficiency of the

furnace and increase fuel consumption.

Air filters should be changed at least once a year. Very

dusty conditions, the presence of animal hair and the like

will require more frequent changing or cleaning.

Summary of Contents for AMP154SD

Page 17: ...17 Figure 9 Furnace Dimensions ...

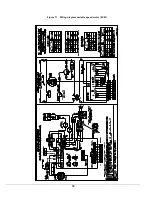

Page 18: ...18 Figure 10 Wiring diagram 4 speed motor PSC ...

Page 19: ...19 Figure 11 Wiring diagram variable speed motor ECM ...

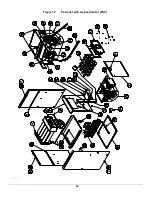

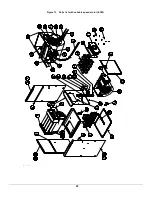

Page 20: ...20 Figure 12 Parts list with 4 speed motor PSC B500111A ...

Page 22: ...22 Figure 13 Parts list with variable speed motor ECM B50112A ...