Assembly and Wiring Procedure

Connect the external wiring to the appropriate terminals

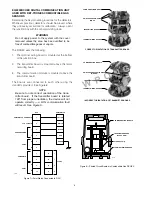

on the DCU terminal wiring board. See Figure 9.

IMPORTANT

Insulate the shields to prevent shorting to the

device housing or to any other conductor.

Attach the sensor to the DCU enclosure. Do not over-

tighten. If a sensor separation kit is being used, attach

the sensor to the separation kit junction box and wire

the device as described below.

CAUTION

The sensor threads can be coated with an appro-

priate grease to ease both the initial installation

and future replacement of the sensor. Detector

Electronics offers a silicone free grease that is

especially suited for use with catalytic type com-

bustible gas sensors (part number 102868-001).

The use of other lubricants is not recommended,

since some materials can cause irreversible dam-

age to the sensing element. SILICONE based

lubricants or compounds must NEVER be used.

Screw the transmitter board to the standoffs as shown in

Figure 8. Connect the sensor plug to the transmitter

board.

Attach the communication module to the standoffs

mounted on the transmitter board. Connect the ribbon

cable from the terminal wiring board to the communica-

tion module.

Set the address for the device (see “Addressability” on

page 3).

Sensor Separation with DCUEX

If the installation requires mounting the sensor in a dif-

ferent location than the DCUEX, observe the following

guidelines.

When separating a combustible gas sensor from the

DCUEX, two options exist:

1. Preferred Method

Mount the transmitter PC board inside the sensor

separation junction box. This assembly can be

separated from the DCUEX by up to 1000 feet using

three conductor 18 AWG shielded cable.

(Regardless of separation distance, operating volt-

age at the transmitter MUST be at least 18 vdc to

ensure proper operation.) See Figure 10.

Assemble the DCUEX without the transmitter board

similar to the DCU as shown in Figure 4. Plug the

sensor into P2 on the transmitter board. Use a

three conductor 18 AWG shielded cable to connect

P1 on the transmitter board to terminals 2, 3 and 4

on the DCU terminal board (see Figure 10).

Connect the shield to the ground terminal in the

DCUEX junction box.

2.

Alternate Method.

If the transmitter board must be mounted separate

from the sensor (high temperature applications,

etc.), separate the sensor only, leaving the transmit-

ter PC board inside the DCUEX enclosure. When

using this installation option, see Table 2 for maxi-

mum wiring distances.

Mount the sensor directly to the separation kit junc-

tion box. Use three conductor shielded cable for

the connection between the terminal block in the

separation kit junction box and P1 on the transmitter

board. A plug with screw terminals is provided for

connecting the cable to P1 on the transmitter board.

Observe the wiring color code. Connect the shield

to the ground terminal in the DCUEX junction box.

7

90-1118

1

2

3

4

5

6

7

8

9

10

SIG

–

+

DCU TERMINAL BOARD

DCU TRANSMITTER BOARD1

(MIDDLE BOARD)

14

13

12

11

–

–

+

+

24 VDC

POINTWATCH CALIBRATE

4 TO 20 MA IN

–

+

A

B

A

B

SENSOR POWER

COM 2

COM SHIELD

COM 1

B1877

NOTES: 1 Catalytic Combustible Gas Sensor

Plugs into Connector Pins on the

Middle Board inside the Junction Box.

2 Connections Wired at the Factory.

2

2

2

Figure 9—DCU Transmitter Board Connected

to Terminal Wiring Board