NOTE

Refer to the Eagle Quantum system manual,

form number 95-8470, for complete instructions

regarding wiring and installation.

EQ2200DCU DIGITAL COMMUNICATION UNIT USED

WITH DET-TRONICS H

2

S/O

2

SENSORS OR OTHER

TWO-WIRE 4 TO 20 MA DEVICES

Determine the best mounting locations for the detectors.

Whenever practical, detectors should be placed where

they are easily accessible for calibration.

WARNING

Do not apply power to the system with the cover

removed unless the area has been verified to be

free of combustible gases or vapors.

The DCU utilizes the following:

1.

A terminal wiring board mounted at the bottom of

the junction box.

2.

A communication module mounted above the termi-

nal wiring board using the standoffs provided. See

Figure 4.

Assembly and Wiring Procedure

Attach the sensor to the DCU enclosure. Do not over-

tighten. If a sensor separation kit is used, attach the

sensor to the separation kit junction box and wire the

device as described in the “Sensor Separation” section.

CAUTION

The sensor threads can be coated with an appro-

priate grease to ease installation. Also lubricate

the cover threads.

Connect the external wiring to the appropriate terminals

on the DCU terminal wiring board. Refer to Figure 5 for

terminal identification. See Figure 6 for an example of a

Det-Tronics electrochemical sensor wired to a DCU.

4

A1571

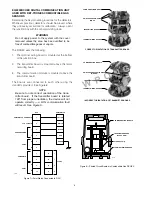

COMMUNICATION MODULE

STANDOFFS (4)

TERMINAL WIRING BOARD

Figure 4—Printed Circuit Boards in Universal DCU

1

2

3

4

5

6

7

8

9

10

14

13

12

11

–

–

+

+

24 VDC

POINTWATCH CALIBRATE

4 TO 20 MA IN

–

+

A

B

A

B

SENSOR POWER

COM 2

COM SHIELD

COM 1

A1726

Figure 5—Terminal Identification for DCU

1

2

3

4

5

6

7

8

9

10

BLACK

RED

GREEN

DCU

H2S/TOXIC/O2

14

13

12

11

–

–

+

+

24 VDC

POINTWATCH CALIBRATE

4 TO 20 MA IN

–

+

A

B

A

B

SENSOR POWER

COM 2

COM SHIELD

COM 1

A1875

Figure 6—Electrochemical Sensor Connected to DCU