19

•

Examine winches and straps to make sure they are in

good condition.

•

Check wheel nuts every trip.

•

Tires must be inflated to recommended pressure by

tire manufacturer.

•

Be certain the safety lock pins lock the strap winches.

•

Retighten the straps over the tires after the first 5 miles

of travel. Check straps every 50 miles there after to

ensure they are tight and not rubbing or fraying.

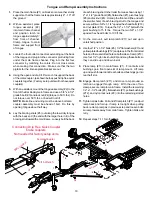

Step 10. Thread tie-down strap through the slotted tube on

the tie-down winch. Pull approx. 6" of strap through this slot.

Begin tightening strap making sure the tail becomes enclosed

by the strap coming over the tire. Tighten the straps ensuring

that the strap fed through the slot binds between the shaft and

the strap being wound onto the winch shaft. While tightening

straps, pull cross strap forward to ensure even tightening.

NOTE: Be sure to tighten straps until each tire starts to

flatten against tire stop.

After each strap is tight, insert a

safety pin in each winch.

Disengage towed vehicle parking

brake.

Straps must be retightened after first 5 miles of travel.

Check straps every 50 miles thereafter to ensure they are

tight and not rubbing or fraying.

Step 14. To pull the Kar Kaddy empty, make sure "Auto-

Steer" LOCKING PIN IS IN PLACE and towing vehicle

safety chains are up and hooked. Tie-down winch handles

should be left in a down postion (horizontal position) with

safety pins in place when towing loaded or empty. DO NOT

ATTEMPT TO PULL KAR KADDY WITH WHEEL PLAT-

FORM IN LOADING (tilted) POSITION.

DAMAGE PREVENTION

Check your vehicle manual or registration for vehicle weight.

Towing vehicle must be larger and at least 1,000 lbs. heavier

than the towed vehicle and tow dolly combined.

Do not pack goods in car that is being towed. Overloading the

Kar Kaddy or exceeding the width limit may result in damage

to both car and Kar Kaddy.

REAR WHEEL DRIVE PRECAUTIONS

Disconnect towed vehicle driveshaft for rear wheel drive

vehicles with automatic transmission. Simply placing trans-

mission in neutral is not sufficient to prevent damage to

transmisssion.

For manual transmission: Consult your vehicle owners

manual for towing suitability with the drive shaft connected.

ALL VEHICLES MOUNTED ON THE KAR KADDY MUST BE

WITH THE FRONT OF THE VEHICLE FACING FORWARD.

Step 12. Hook the towed vehicle safety chains to frame of

vehicle directly above the area where the chains are mounted

on the Kar Kaddy. Leave some slack in the chains to allow

suspension movement of the towed vehicle.

Step 11. Make sure the tie-down strap is the correct size for

the auto tire. See page 4 of this instruction for proper fit and

exchange instructions.

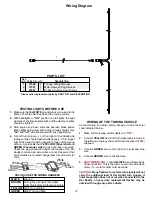

Step 13. TO UNLOAD towed vehicle.

Never unhook tow

dolly coupler from towing vehicle, before unloading

todolly.

Make sure that platform and vehicle are straight.

Reinstall driveshaft. Ensure that towed vehicle parking brake

is fully engaged, then unhook the towed vehicle safety chains,

and release the tie-down straps.

NOTE:

Tie down straps

must be "quick -released" by grasping ratchet pawl (A) and

ratchet handle (B) simultaneously and pushing down sharply.

This process will permit easy removal of strap from winch.

Grasp bed release handle on tongue and pull toward coupler.

This releases the tilt bed to permit unloading. This will allow

the platform to tilt as you slowly drive off. Make sure the winch

ratchet handles are horizontal. Replace the "Auto Steer"

locking pin (for towing empty).

SAFETY

A

B

Summary of Contents for Kar-Kaddy SS KK460SS

Page 1: ...1 7 06 RD20010 Rev 6...

Page 32: ...32 NOTES...

Page 34: ...34 Postage Dethmers Manufacturing Company 4010 320th Street Box 189 Boyden Iowa 51234...

Page 35: ...35 NOTES...