8

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

ASSEMBLY TIME ESTIMATE

Open end wrenches (supplied)

Hex wrenches (supplied)

Flat screwdriver (not supplied)

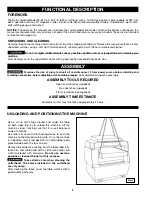

Use a crane with slings around and under the table

on both sides (Fig. 2) to unload this machine. Lift the

machine slowly, making sure that it is well balanced.

Lower it carefully.

Use rollers or some similar hauling device to push the

machine to the desired working site. Once the machine

is in position, level it and position it on hard rubber pads

placed underneath the four corners.

Remove the protective coating from the table, bed rolls,

feed rolls, and cutterhead with a stiff brush and/or soft

cloth moistened with kerosene.

Do not use acetone,

gasoline or lacquer thinner for this purpose.

Take extreme care when cleaning the

cutterhead. The knives installed in the cutterhead

are very sharp.

After cleaning the table, cover the table surface with a

good quality paste wax.

Assembly for this machine takes approximately 2 hours.

Fig. 2

UNLOADINg AND POSITIONINg THE MACHINE

UNPACkINg AND CLEANINg

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your

machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and

removing accessories, before adjusting or when making repairs.

An accidental start-up can cause injury.

FOREWORD

FUNCTIONAL DESCRIPTION

NOTICE:

The photo on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These are are intended

to illustrate technique only.

The Delta Indusrial Model 22-610 is a 24-3/4" (629 mm) Planer with a 10

HP, three-phase motor capable of 230 V or

460 V operation with an LVC magnetic starter, 4-knife cutterhead, infeed and outfeed rollers, chipbreakers, dust chute,

knife-setting gauge, and wrench.

Summary of Contents for 22-610

Page 63: ...63 NOTES NOTAS ...