15

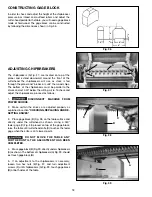

CHECKING AND ADJUSTING DRIVE BELT TENSION

Proper belt tension is when there is approximately 1/4" deflection, using light finger pressure on the drive belts (A) Fig.

28, midway between pulleys. If an adjustment is necessary, proceed as follows:

Fig. 28

1.

DISCONNECT MACHINE FROM

POWER SOURCE.

2.

Disengage feed roller lever (B) Fig. 28.

3.

Loosen and tighten two adjustment nuts (C) Fig. 29, to

move motor plate up or down as necessary to increase or

decrease drive belt tension.Tighten both adjustment nuts

(C) against plate (D) Fig. 29, after adjustment is made.

4.

Close both side panels.

Fig. 29

A

B

C

D