GENERAL

SM6000

9 / 21

DELTA ELEKTRONIKA B.V.

rev. Nov. 2020

3.16

FUNCTION SWITCHES ON SW1

In the table on the previous page the functions of the DIP

switches 1-5 of switch SW1 at the rear side are explained.

3.17

REMOTE SHUTDOWN (RSD)

A voltage of +4...+12 V on the RSD input on the programming

connector CON E will switch off the output of the unit.

It is also possible to use a relay contact or a switch to shut the

unit down (see fig. 3 - 11). In standby mode the power supply

consumes very little power.

3.18

INTERLOCK

The Interlock connector CON A has 2 pins (1 & 3) which have

to be connected together to enable the unit, see fig. 3 - 12.

As soon this connection is interrupted, the DC output of the

unit shuts down. It can be used in combination with door

contacts (safety precaution) or as an emergency stop.

In case the connection is interrupted the RSD LED will light.

In contrast with Remote ShutDown, also the DCF LED will be

on, DCF status will be high and the relay contact will change.

Once the inputs are reconnected, the DC output will be on

again.

The interlock circuit is at the same level as the analog ground,

the S- and the minus DC power terminal. The interlock circuit

needs voltage free contacts and can not be connected in

parallel or series with other interlocks .

3.19

PROGRAMMING SPEED

The rise and fall time is measured with a step waveform at the

CV prog. input. Programming from a low to a high output

voltage is nearly load independent, but programming down to

a low voltage takes more time on lighter loads. This is caused

by the output capacitors, which can only be discharged by the

load because the power supply cannot sink current. With the

Power Sink option, also the programming down speed is

nearly load independent.

When having a unit with a hi speed programming option, the

rise and fall time is 5 to 25 times faster (see datasheet). The

programming source must be floating or otherwise an ISO

AMP CARD must be used, a non-floating source will result in

slope distortion.

When using hi speed programming it is generally not

recommended to use remote sensing or serial / parallel

operation. Consult factory for advice. Note that the output

ripple is higher.

3.20

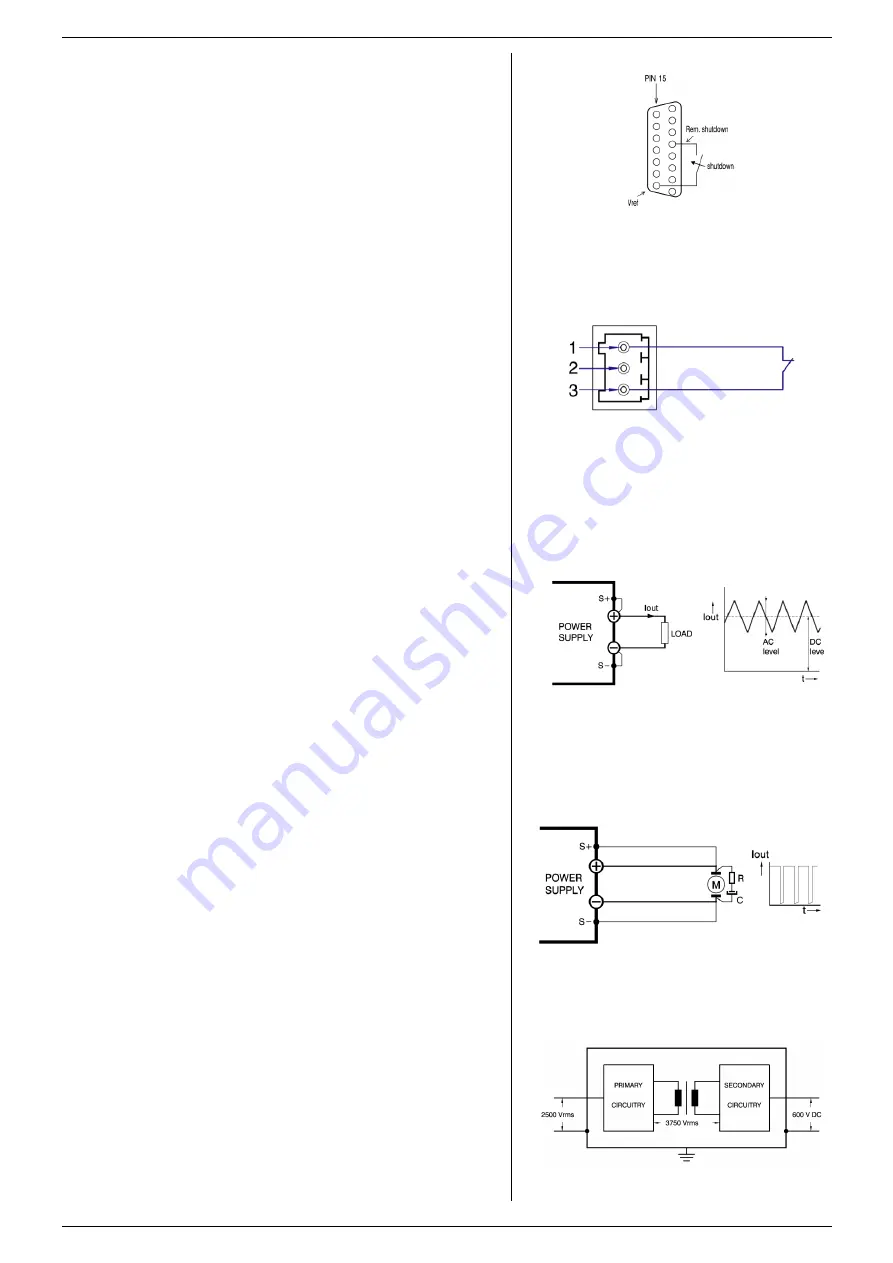

PULSATING LOAD

To avoid overheating the DC output capacitors, the AC

component of the load current should be limited (fig. 3 - 13).

One method of decreasing the AC current through the output

capacitor is by using a large external electrolytic capacitor in

parallel with the load. Care must be taken so that the

capacitor in combination with the lead inductance will not form

a series resonant circuit!

When using remote sensing on a pulsating load (for instance

a DC-motor), use a capacitor in series with a resistor over the

load (see fig. 3 - 14). Like this the AC-component caused by

the pulsating of the load is filtered.

Note: in case of a pulsating load, the I monitor voltage will not

exactly match the output current. This is mainly caused by the

current through the output capacitors. Remote sensing will

worsen this effect.

3.21

INSULATION

For safety the insulation of the separating components

(transformers) between mains in and DC output is tested at

3750 Vrms during 1 minute. This is tested before assembly.

Warning! The 3750 Vrms cannot be tested afterwards on the

assembled unit because the insulation between the

components on the AC side to the case (like the bridge

rectifier) is specified at 2500 Vrms. Since the insulation of DC

power terminals -> case is 600 VDC, the insulation of the

primary components to case will break down when 3750 Vrms

fig 3 - 11

Remote Shut Down using a relay contact.

fig 3 - 12

Interlock connection at CON A. Connect between pin

1 and pin 3, do not use pin 2.

fig 3 - 13

Pulsating load current.

fig 3 - 14

Remote sensing on a pulsating load.

fig 3 - 15

Insulation test voltages.