MAINTENANCE & CALIBRATION

SM6000

20 / 21

DELTA ELEKTRONIKA B.V.

rev. Nov. 2020

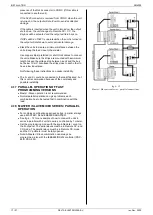

fig 6 -1

The fans are located at the left side and blow

through the tunnels.

6

MAINTENANCE & CALIBRATION

6.1

GENERAL

The SM-series power supplies do not need any maintenance

or calibration. However, care must be taken that the cooling

unit is not obstructed.

6.2

COOLING FANS

The internal construction of the power supply is such that no

dust will reach the sensitive control circuitry, only the heat

sinks in a tunnel will be cooled by forced air (see fig. 6 - 1)

The built up of dust on the impellers of the fans and the heat

sink fins depends on the environment. It is advised to inspect

the fans and heat sinks regularly.

Since the used fan type has an over-capacity, dust will not

present a problem very quickly.

The thermal protection will shutdown the output in case of

overheating, so no damage will be done to the power supply.

6.3

GALVANIC INDUSTRY

For using the power supplies in the galvanic industry it is

strongly recommended to take precautions against an

aggressive environment.

An aggressive environment with acid, salt, etc. can harm the

electronic components. Sometimes even the copper tracks on

the printed circuit boards dissolve.

To avoid problems, the power supplies should be mounted in

a relatively clean room, in a cabinet receiving clean air with

over pressure, or a cabinet with a heat exchanger.

6.4

CALIBRATION

The power supplies are factory calibrated and normally need

no further calibration.

After installation of a new or different interface, no calibration

is needed.

Only in special situations, for example after repairing a unit,

calibration can be necessary.

6.5

METER CALIBRATION

DIGITAL METERS

The full scale indication can be calibrated with R25_31 and

R25_36 on P596 (see fig. 6 - 2).

6.6

SPECIAL CALIBRATIONS

The following calibrations must be done by qualified

personnel only. Wrong calibration causes malfunction. These

calibrations are only needed after special repairs.

Warning !

Damage caused by wrong calibration is not

warranted.

CALIBRATING THE CURRENT

MONITOR OFFSET.

With R26_73 on P597 the offset of the CC monitor voltage

can be calibrated (see fig. 6 - 3). The unit has to be unloaded,

the output voltage has to be turned off using the OUTPUT

ON/OFF button. Measure the offset voltage of the CC monitor

on the programming connector. Calibrate the offset on a

negative value between

–1 mV and 0 mV.

Warning!

wrong calibration can damage the unit.

CALIBRATING MAX. CURRENT RANGE or CALIBRATING

CC MONITOR FULL SCALE.

Short the output using a low resistive cable. Measure the

output current with an accurate shunt. The maximum output

current can be calibrated with R26_41. R26_41 is located on

P597 (see fig. 6 - 3).

Program CC input with exactly 5.00 V.

Set output voltage to a high value, ensuring the power supply

is in CC mode. Calibrate the current with R26_41 exactly on

the rated maximum current.

Warning!

Wrong calibration can damage the unit.

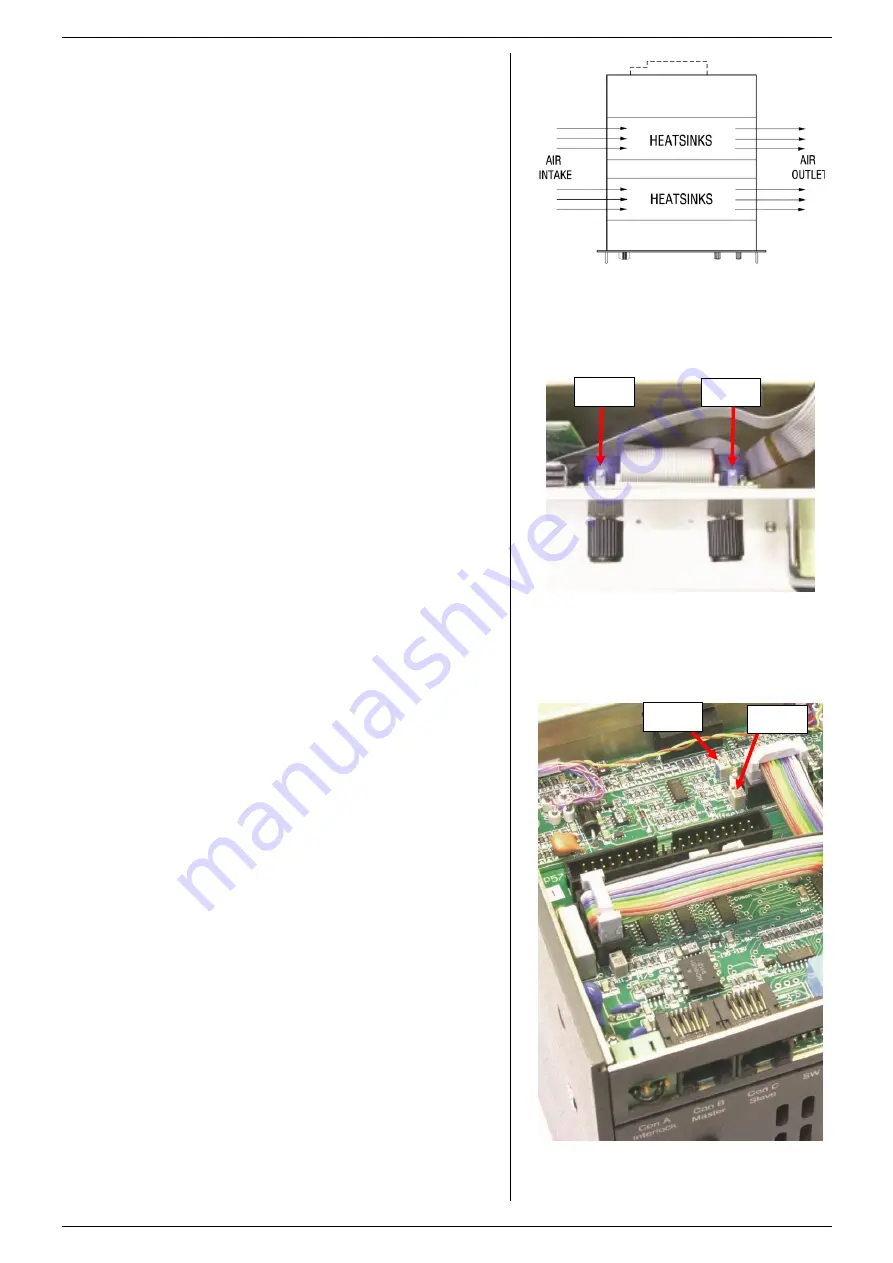

fig 6 -2

Meter calibration with 25-turn potmeters on P596.

fig 6 -3

Calibrating maximum current and offset on P597.

V-meter

A-meter

R26_73

R26_41