Chapter 2 – Printer Setup

7

To simplify the adjustment, the AMS uses Reference Letter designators that correspond to the following TOF

mark distances:

Distance of the TOF Mark from the Media Edge

Reference

Letter

(inches)

(millimeters)

A .180

4.6

B .500

12.7

C .750

19.1

D 1.00

25.4

E 1.25

31.8

F 1.50

38.1

G 1.75

44.5

H 2.00

50.8

I 2.25

57.2

J 2.50

63.5

K 2.75

69.9

L 3.00

76.2

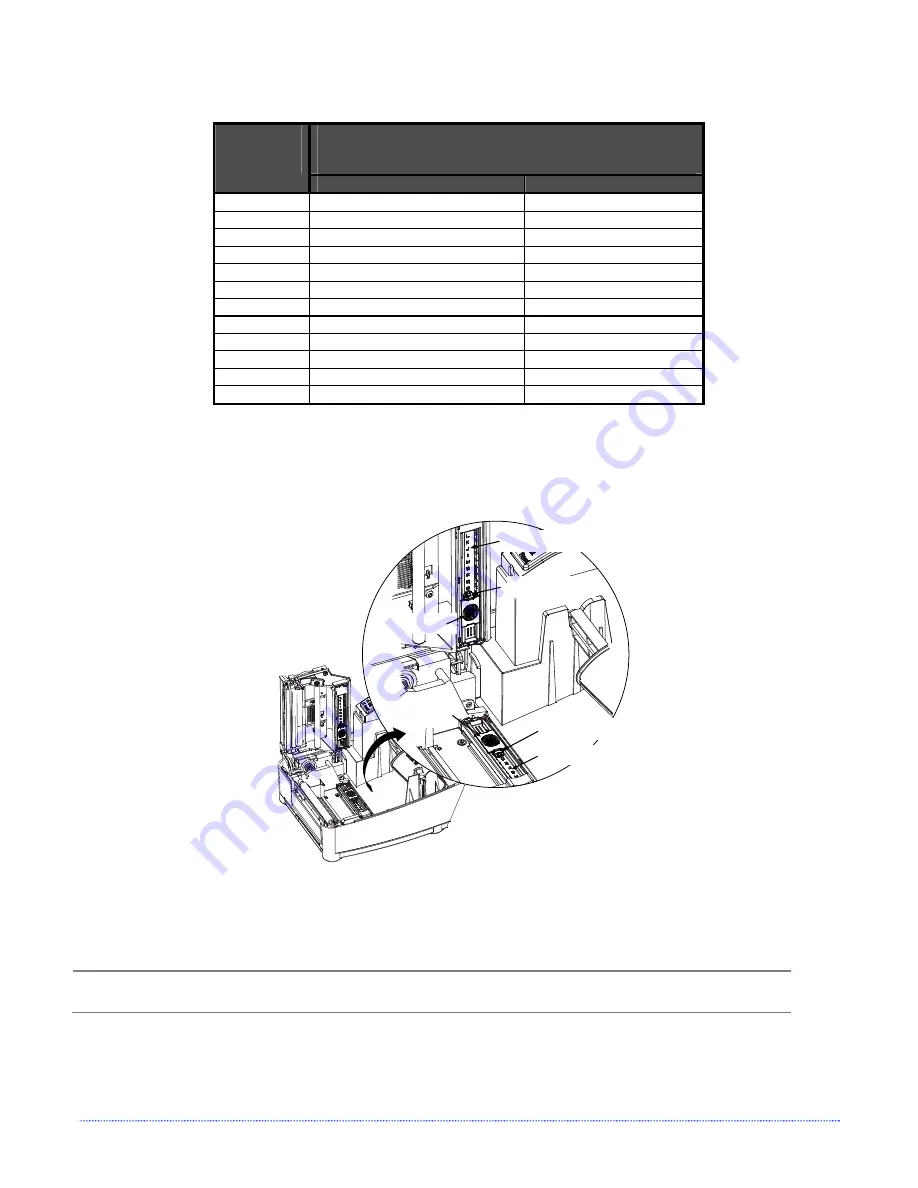

Position the Adjustable Media Sensor as follows:

1. Based on the measurement made earlier, choose the Reference Letter that best corresponds to the

location of your TOF mark.

Top Slide

Bottom Slide

Reference Letters

Reference Letters

Setting Window

Setting Window

2. Use a finger to move the Bottom Slide until your selected Reference Letter appears in the Setting Window

of the slide.

3. Use a finger to move the Top Slide until your selected Reference Letter appears in the Setting Window of

the slide.

The Top and Bottom Slides must be positioned over the same Reference Letter for proper media

sensor function.

4. Proceed to ‘Loading Media’ (Section 2.4).

Summary of Contents for Mark II E-4205e

Page 1: ...Operator s Manual...

Page 2: ......

Page 8: ...2 Chapter 1 Getting Started...

Page 41: ...Appendix A Specifications 35...

Page 56: ...50 Appendix B Internal Menu...

Page 72: ...Glossary...