COMPONENT SPECIFICATION

C00525

C00525

C00525

C00525

- 13 -

APPENDIX 4 – TEST FOR LATCH INTEGRITY

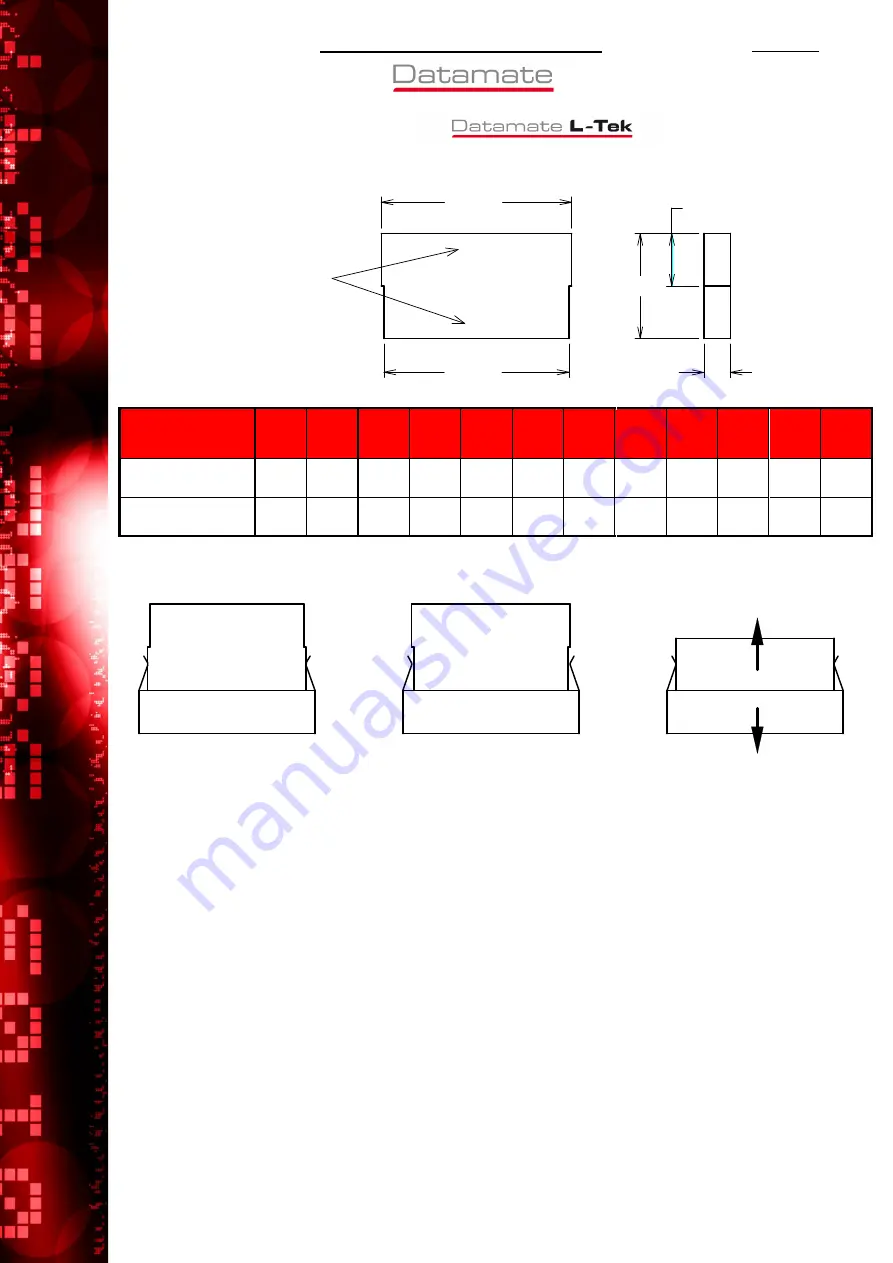

A4.1. LATCH INTEGRITY GAUGE

B

A

20

10

5

Dim ‘B’

Dim ‘A’

Remove all burrs

and sharp edges

‘A’ and ‘B’ stamped

in positions shown

No. of contacts

No. of contacts

No. of contacts

No. of contacts

per row

per row

per row

per row

2222

3333

4444

5555

6666

7777

8888

9999

10

10

10

10

13

13

13

13

17

17

17

17

22

22

22

22

Dim ‘A’

+0.00 / -0.02

6.00

8.00

10.00 12.00 14.00 16.00 18.00 20.00 22.00 28.00 36.00 46.00

Dim ‘B’

+0.02 / -0.00

5.00

7.00

9.00

11.00 13.00 15.00 17.00 19.00 21.00 27.00 35.00 45.00

A4.2. LATCH INTEGRITY TEST

B

A

B

A

Figure 1

Figure 2

Figure 3

When Gauge A is placed between the two faces of the latch clips (as shown in Figure 1), the connector

shall be held against its own weight.

When Gauge B is placed between the two faces of the latch clips (as shown in Figure 2), the connector

shall not be held against its own weight.

When an unloaded female connector moulding is mated with a latched male connector, and a force of

20N is applied for 10 seconds in the directions shown in Figure 3, there shall be no failure of any part

of the latch mechanism.