DATALOGIC AUTOMATION - TH-TS series

– INSTRUCTION MANUAL - Rev. 04 - PAGE 10

GROUP “

]

PAn” (PARAMETERS RELATIVE TO THE USER

INTERFACE) : This contains the parameters relative to the key T

and display functions.

Usrb –

KEY T FUNCTION : Decides which function is associated to

key T. The possible selections are :

= noF : no function

= tunE : Pushing the key for 1 sec. at least, it is possible to

activate/deactivate the Autotuning or the Self-tuning

= OPLO : Pushing the key for 1 sec. at least, it is possible to swap

from the automatic control (rEG) to the manual one (OPLO).

= Aac : Pushing the key for 1 sec. at least, it is possible to

acknowledge the alarm.

= ASi : Pushing the key for 1 sec. at least, it is possible to

acknowledge an active alarm

= CHSP : Pushing the key for 1 sec. at least, it is possible to select

one of the 4 pre-programmed Set Points on rotation.

= OFF : Pushing the key for 1 sec. at least, it is possible to swap

from the automatic control (rEG) to the OFF control (OFF).

diSP -

VARIABLE VISUALISED ON THE DISPLAY:

Parameter

through which it is possible to decide what is visualised on the

display : the process variable (= dEF), the control power (= Pou), the

active Set Point (= SP.F), the Set Point active when there are ramps

(= SP.o) or the alarm threshold AL1 (= AL1).

AdE -

SHIFT VALUE FOR THE SHIFT INDEX FUNCTIONING: This

allows one to decide the functioning mode of the 3 led shift indexes.

The lighting of the green led “=” indicates that the process value is

within the range [SP+AdE ... SP-AdE], the lighting of the red led “-”

indicates that the process value is lower than the value [SP-AdE]

and the lighting of the red led “+”indicates that the process value is

higher than the value [SP+AdE].

Edit

- FAST PROGRAMMING OF ACTIVE SET POINT AND

ALARMS: This decides which are the Sets that can be programmed

by the fast procedure. The parameter can be programmed as :

=SE: The active Set Point can be modified while the alarm

thresholds cannot be modified

=AE :The active Set Point cannot be modified while the alarm

thresholds can be modified

=SAE: If the active Set Point or the alarm thresholds can be modified

=SAnE: If the active Set Point or the alarm thresholds cannot be

modified

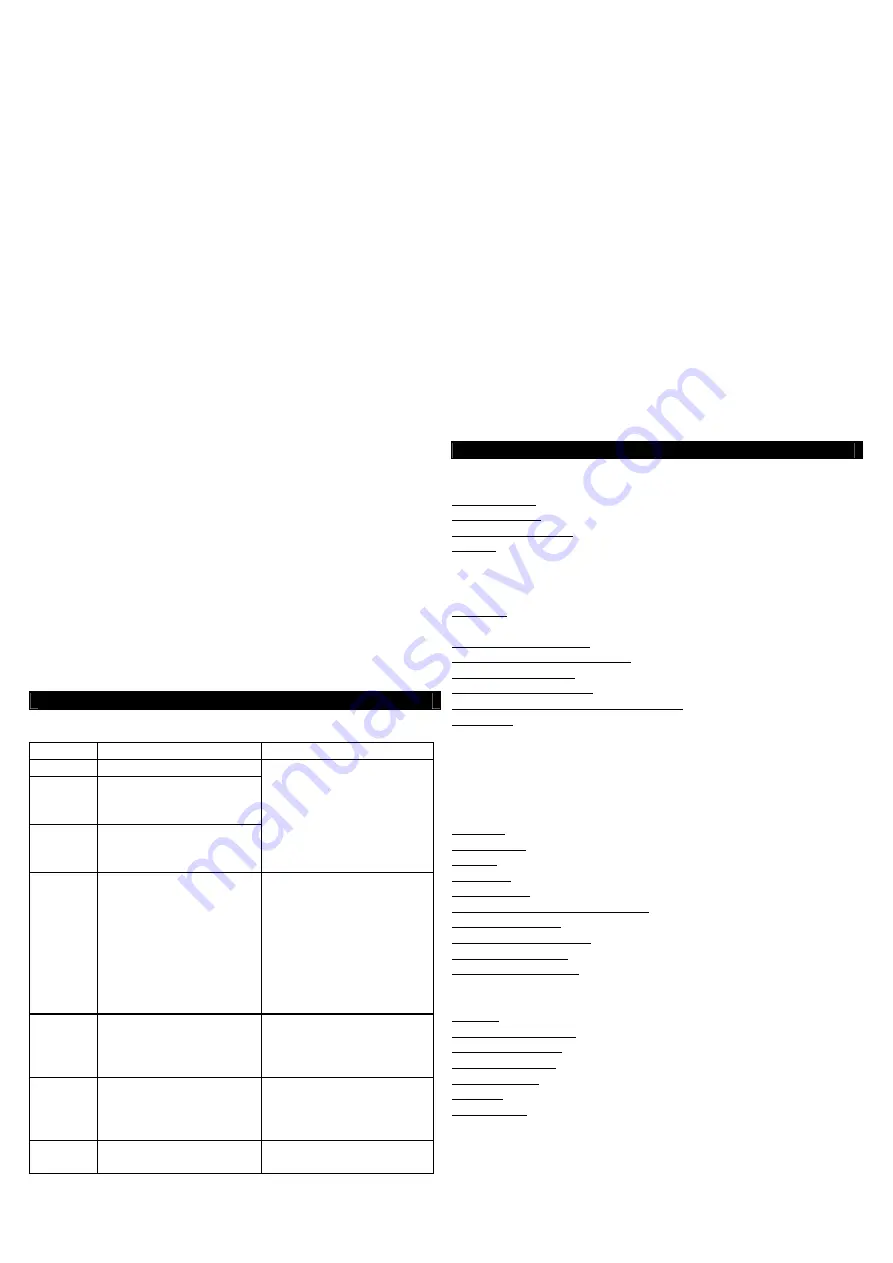

6 - PROBLEMS, MAINTENANCE AND GUARANTEE

6.1 - ERROR SIGNALLING

Error

Reason

Action

- - - -

Probe interrupted

uuuu

The measured variable

is under the probe’s

limits (under-range)

oooo

The measured variable

is over the probe’s

limits (over-range)

Verify the correct

connection between

probe and instrument and

then verify the correct

functioning of the probe

ErAt

Auto-tuning not possible

because the process

value is higher (with

“Func” =HEAt) than [SP-

|SP/2|] or lower (with

“Func” =CooL) than

[SP+ |SP/2|].

Swap the instrument to

OFF control (OFF) and

then to automatic control

(rEG) in order to make

the error message

disappear.

Once the error has been

found, try to repeat the

auto-tuning.

noAt

Auto-tuning not finished

within 12 hours

Check the functioning of

probe and actuator and

try to repeat the auto-

tuning.

LbA

Loop control interrupted

(Loop break alarm)

Check the working of

probe and actuator and

swap the instrument to

(rEG) control

ErEP

Possible anomaly of the

EEPROM memory

Push key “P”

In error conditions, the instrument provides an output power as

programmed on par “OPE” and activates the desired alarms, if the

relative parameters “ALni” have been programmed = yES.

6.2 - CLEANING

We recommend cleaning of the instrument with a slightly wet cloth

using water and not abrasive cleaners or solvents which may

damage the instrument.

6.3 - GUARANTEE AND REPAIRS

The instrument is under warranty against construction vices or

defected material, if noticed within the terms in force at the

purchasing date.

The guarantee is limited to repairs or to the replacement of the

instrument.

The eventual opening of the housing, the violation of the instrument

or the improper use and installation of the product will bring about

the immediate withdrawal of the warranty’s effects.

In the event of a faulty instrument, either within the period of

warranty, or further to its expiry, please contact our sales department

to obtain authorisation for sending the instrument to our company.

The faulty product must be shipped to DATALOGIC AUTOMATION

with a detailed description of the faults found, without any fees or

charge for DATALOGIC AUTOMATION, except in the event of

alternative agreements.

7 - TECHNICAL DATA

7.1 – ELECTRICAL DATA

Power supply: 24 VAC/VDC, 100... 240 VAC +/- 10%

Frequency AC: 50/60 Hz

Power consumption: 5 VA approx.

Input/s: 1 input for temperature probes: tc J,K,S ; infrared sensors

IRS J and K; RTD Pt 100 IEC; PTC KTY 81-121 (990

@ 25 °C);

NTC 103AT-2 (10K

@ 25 °C) or mV signals 0...50 mV, 0...60 mV,

12 ...60 mV

Output/s: Up to 2 outputs. Relay SPST-NO (8 A-AC1, 3 A-AC3 / 250

VAC) ; or in tension to drive SSR (8mA/ 8VDC).

Auxiliary supply output: 10 VDC / 20 mA Max.

Electrical life for relay outputs: 100000 operat.

Installation category: II

Measurement category: I

Protection class against electric shock: Class II for Front panel

Insulation:

Reinforced insulation between the low voltage section

(supply and relay outputs) and the front panel; Reinforced insulation

between the low voltage section (supply and relay outputs) and the

extra low voltage section (inputs, SSR outputs); No insulation

between input and SSR outputs.

7.2 – MECHANICAL DATA

Housing: Self-extinguishing plastic, UL 94 V0

Dimensions: 48 x 48 mm DIN, depth 98 mm

Weight: 225 g approx.

Mounting: Flush in panel in 45 x 45 mm hole

Connections: 2 x 1 mm

2

screw terminals block

Degree of front panel protection : IP 54 mounted in panel with gasket

Pollution situation: 2

Operating temperature: 0 ... 50 °C

Operating humidity: 30 ... 95 RH% without condensation

Storage temperature: -10 ... +60 °C

7.3 – FUNCTIONAL FEATURES

Control: ON/OFF, single and double action PID

Measurement range: according to the used probe (see range table)

Display resolution: according to the probe used 1/0,1/0,01/0,001

Overall accuracy: +/- 0,5 % fs

Sampling rate: 130 ms.

Display: 4 Red Digit h 12 mm

Compliance: ECC directive EMC 89/336 (EN 61326), ECC directive

LV 73/23 and 93/68 (EN 61010-1)