CBX ELECTRICAL CONNECTIONS

39

3

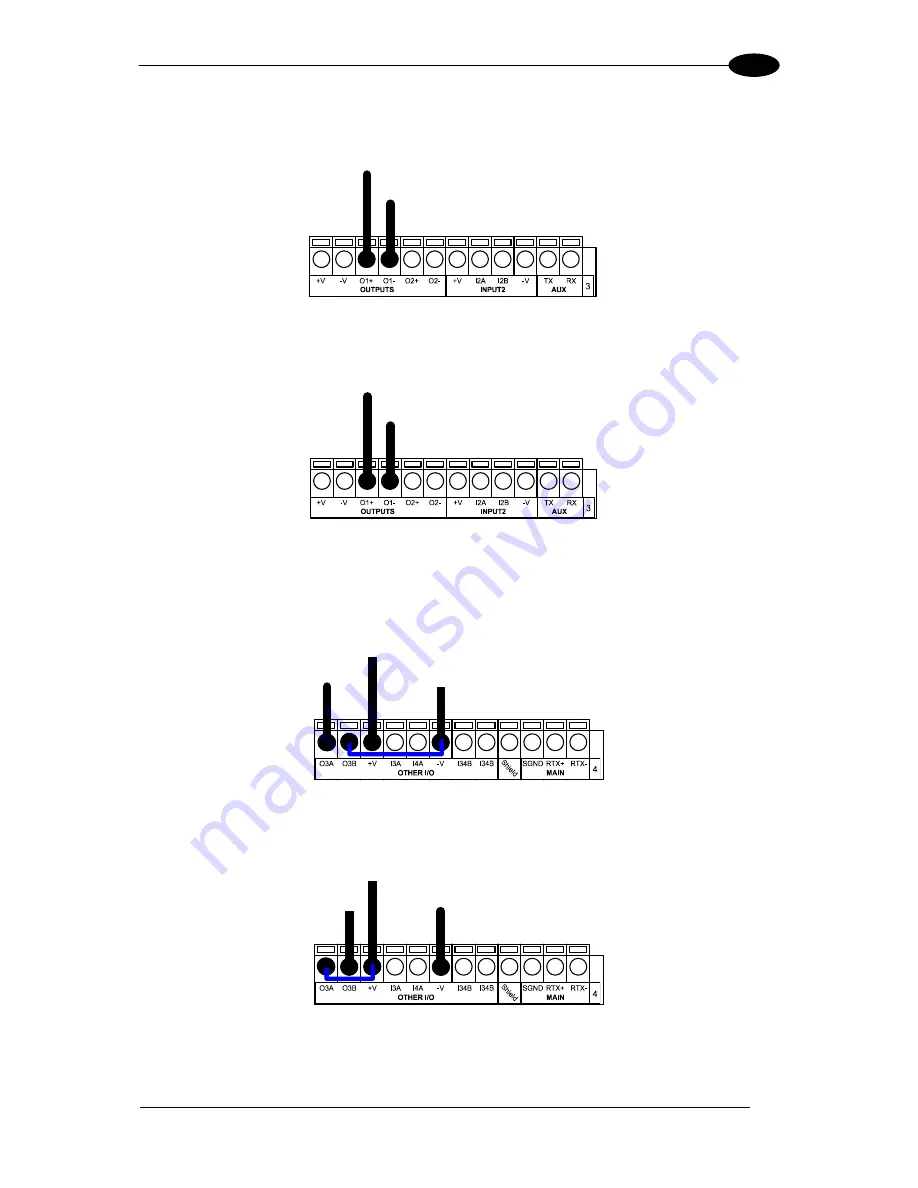

OUTPUT 1 and 2 CONNECTIONS USING EXTERNAL POWER

Output Device

Power Reference

Output

Signal

Output Device

Figure 47 - Open Emitter Output Using External Power

Output Device

Ground Reference

Output

Signal

Output Device

Figure 48 - Open Collector Output Using External Power

OUTPUT 3 CONNECTIONS USING DS6400 POWER (CBX500 Only)

Power to

Output Device

Output

Output Device

Signal

Reference

Output Device

Figure 49 - Output 3 Using DS6400 Power

Power to

Output Device

Output

Output Device

Signal

Ground Reference

Output Device

Figure 50 - Output 3 Using DS6400 Power

Summary of Contents for DS6400

Page 1: ...DS6400 Reference Manual ...

Page 159: ...www datalogic com ...