Single compressors

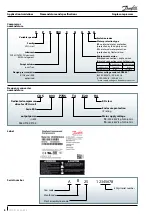

Electrical data, connections and wiring

The CDS803 frequency converter generates by

design a compressor soft start with an default

initial ramp up of 7.5s to 50 rps.

Current inrush will not exceed the frequency

converter maximum current.

Basically seen from the mains the inrush peak

reach a level which is only a few percent more

than the rated nominal current.

Soft-start control

The compressor will only operate properly in a

single direction. If electrical connections are done

correctly between the drive and the compressor

terminals (compressor and drive terminals U, V &

W matching), the drive will provide correct phase

supply to the compressor, and reverse rotation

will be not possible:

• CDS803 terminal U (96) to VZH terminal T1/U

• CDS803 terminal V (97) to VZH terminal T2/V

• CDS803 terminal W (98) to VZH terminal T3/W

If compressor and drive U, V & W terminals are

not matching, the compressor can operate in a

reverse rotation. This results in excessive noise,

no pressure differential between suction and

discharge, and suction line warming rather than

immediate cooling. The compressor can be

rapidly damaged in these conditions. To protect

compressors from reverse rotation, one of below

actions is required:

- Use pressure sensors to monitor pressure

difference between discharge and suction of

the compressor, and for normal operation,

discharge pressure should be at least 1 bar

higher than suction pressure within 30 s

running after compressor starting.

- Apply the dome temperature sensor on top of

the compressor upper shell to sense the high

temperature resulted from compressor reverse

run and trigger the alarm in system controls.

Mains connection to the CDS803 frequency

converter order has no influence on the output

phase sequence which is managed by the

frequency converter.

The compressor terminal box IP rating according to IEC529 is IP22.

VZH scroll compressors are not equipped with

an internal motor protector. Motor protection

is provided by the variable speed drive. All

parameters are factory preset in order to

guaranty locked rotor or overload current

protection.

When a warning situation is reached in the

current control, the CDS803 frequency converter

will automatically reduce the compressor

speed in order to keep the motor current of the

compressor below the maximum allowed.

In some cases when compressors stop under

low mass flow low speed condition, discharge

valve may not seal discharge port fast enough,

thus compressors may run in a reverse rotation

due to the residual pressure difference and

generate a big noise. Running in the wrong

direction will reduce the reliability and lifetime

of the compressor. The drive shall prevent the

compressors scroll set from running the wrong

way during stop with anti reverse protection.

To activate the function, the customer must be

able to enable and disable the ANTI-REVERSE

PROTECTION.

Phase sequency and

reverse rotation

protection

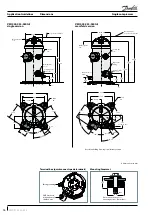

IP rating

Motor protection

Anti-reverse protection

Element

Numerals or letters

Meaning for the protection of equipment

First characteristic

numeral

0

1

2

3

4

5

6

Against ingress of solid foreign objects

(non protected)

≥ 50 mm diameter

≥ 12.6 mm diameter

≥ 2.5 mm diameter

≥ 1.0 mm diameter

dust protected

dust tight

Second

characteristic

numeral

0

1

2

3

4

5

6

7

8

Agains ingress of water with harmful effects

(non protected

vertically dripping

dripping (15° tilted)

spaying

splashing

jetting

powerful jetting

temporary immersion

continuous immersion

22

FRCC.PC.034.A2.02

Application Guidelines