1

Single, Double, T riple and Thru-drive Pumps Overhaul Service Manual V-PUVN-TS001-E October 2002

Section IV —

Installation and Operating

Instructions (cont.)

F. Overload Protection

Self pr iming: W ith a minimum

drive speed of 600 RPM, a

pump should prime

immediately. Failure to prime

within a short length of time

may result in damage due to

lack of lubrication. Inlet lines

must be tight and free from air

leaks. However, it may be

necessary to loosen a fitting on

the outlet side of the pump to

purge entrapped air.

No load star ting: These

pumps are designed to start up

with no load on the pressure

ports. They should never be

started against a load or a

closed center valve.

E. Hy draulic Fluid Recommendations (cont.)

Sound Lev el

Noise is indirectly af fected by

the fluid selection, but the

condition of the fluid is of

paramount importance in

obtaining optimum reduction

of system sound levels.

Some of the major factors

affecting fluid conditions that

cause the loudest noises in a

hydraulic system are:

1. Very high viscosities at start-

up temperatures can cause

pump noises due to cavitation.

2. Running with a moderately

high viscosity fluid will slow

the release of entrained air. The

fluid will not be completely

purged of such air in the time it

remains in the reservoir and air

will be recycled through the

system.

3. Aerated fluid can also be

caused by ingestion of air

through the pipe joints of inlet

lines, high velocity discharge

lines, cylinder rod packings, or

by fluid discharging above the

fluid level in the reservoir. Air in

the fluid causes a noise similar

to cavitation.

4. Contaminated fluids can

cause excessive wear of

internal pump parts, which

may result in increased

sound levels.

Relief valves must be installed

in the system as close to the

pump outlets as possible. The

relief valve limits pressure in

each system to a prescribed

maximum and protects

components from excessive

pressure. Each relief valve

pressure setting depends on

the work requirements of the

circuit being fed.

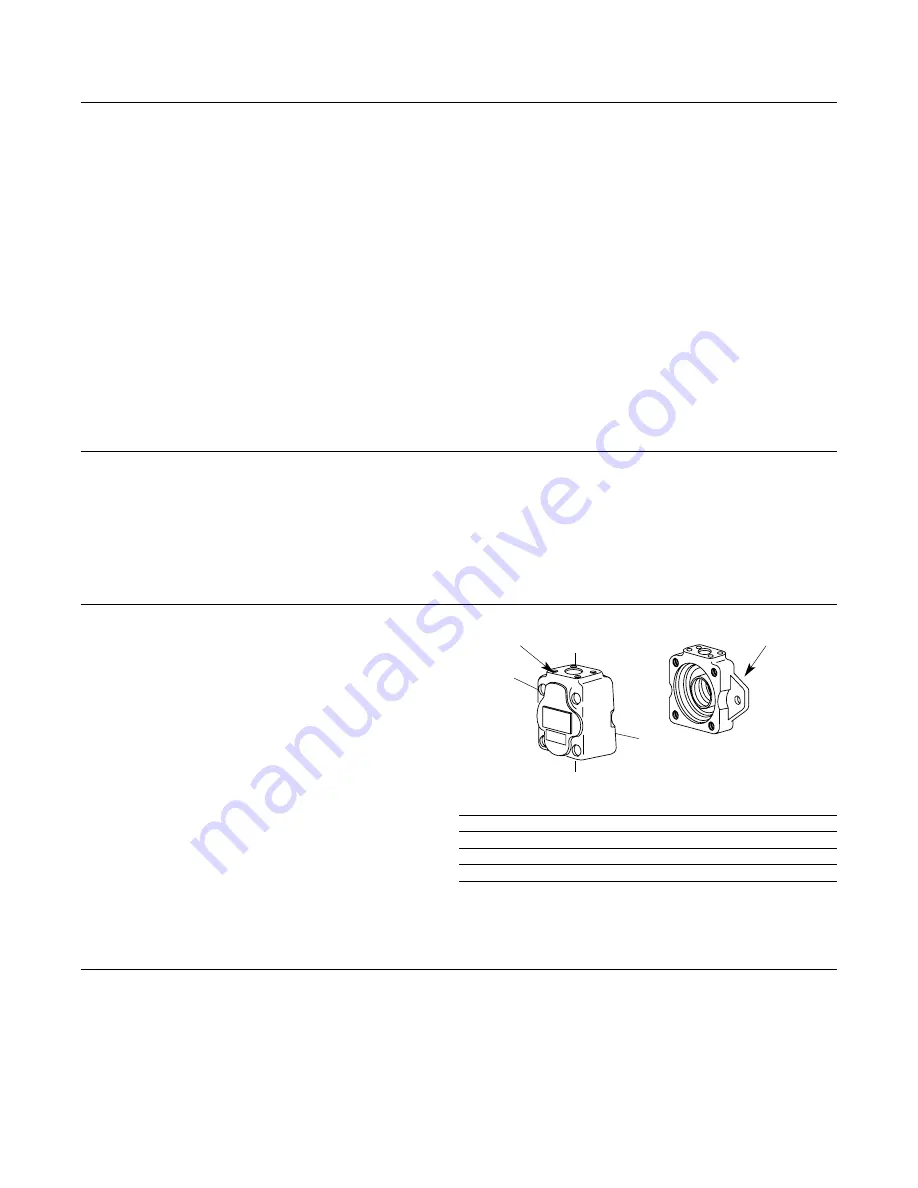

G. P ort Positions

H. Start-Up

The pump cover can be

assembled in four positions

with respect to the body.

A letter in the model code

identifies the orientation of the

inlet and outlet ports. The cover

position of a VMQ single pump

is shown in Figure 8 as an

example.

I

nlet Cover Positions

Model

(Viewed from cover end)

t

r

o

P

t

e

lt

u

O

e

ti

s

o

p

p

O

0

3

0

*

*

A

*

*

1

Q

M

V

0

9

0

3

0

*

*

B

*

*

1

Q

M

V

°Clockwise from Outlet

VMQ1* *C* * 030

Inline with Outlet

VMQ1* *D* * 030

90° Counterclockwise from Outlet

Figure 8.

Cover Positions

Disassembly and assembly procedures are in Section

VI-B and E.

Whenever it is possible to do

so, fill the pump ports with

system hydraulic fluid. This

will make it easier for the

pump to prime when it is first

started.

Body (Outlet)

Cover (Inlet)

A

B

C

D

Summary of Contents for Vickers VMQ125S

Page 22: ......