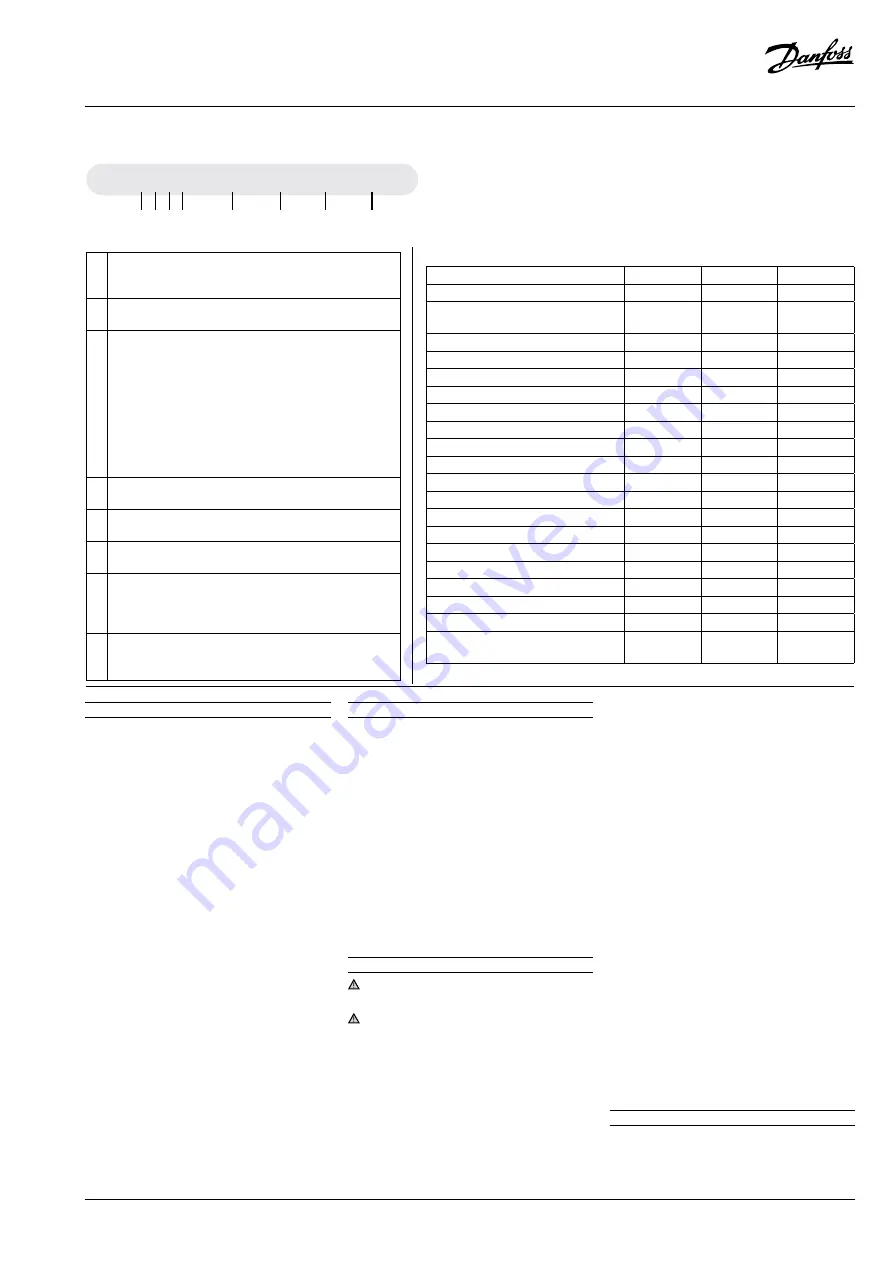

OP - MPXM 034 ML P00 G

1 2 3 4

5

6

7

8

1 Application

M = MBP

L = LBP

2 Package

Condensing unit family: P = Optyma™ Plus

3 Refrigerant

H = R404A/R507

G = R134a, R513A

Q = R452A, R404A/R507

X = R404A/R507, R134a, R407A, R407F, R448A, R513A

R449A,R452A

Y = R404A/R507, R449A

B = R448A/R449A/R404A/R452A (MBP)

P = R448A/R449A, R407A/F, R404A/R507

O = R448A/R449A/R404A/R452A (LBP)

4 Condenser

M = Microchannel heat condenser

5 Swept volume

Displacement in cm

3:

Example 034 = 34 cm

3

6 Compressor platform

ML= Fixed speed scroll MLZ

7 Version

P00: Optyma™ Plus

P02: Optyma™ Plus with Liquid Injection

P05: Optyma™ Plus with Supply monitoring relay

8 Voltage code

G = 230V/1-phase/50Hz compressor & fan

E = 400V/3-phase/50Hz compressor & 230V/1-phase fan

Optyma™

Plus

(P00)

(P02)

(P05)

IP level

IP54

IP54

IP54

Compressor technology

Scroll/

Reciprocating

Scroll

Scroll (3phase)

Control box (pre-wired E-panel)

yes

yes

yes

Microchannel condenser

yes

yes

yes

Fan speed controller*

yes

yes

yes

Main switch (circuit breaker)

yes

yes

yes

Supply monitoring relay

-

-

yes

Filter drier (flare connections)

yes

yes

yes

Sight glass

yes

yes

yes

Crankcase heater

yes

yes

yes

HP/LP adjustable pressostat

Electronic

Electronic

Electronic

Fail safe mini-pressostat

Mechanical

Mechanical

Mechanical

Access door(s)

yes

yes

yes

Acoustic insulation

yes

yes

yes

Condensing unit electronic controller

yes

yes

yes

Network connectivity

yes

yes

yes

Stack mounting

yes

yes

yes

Discharge gas thermostat

yes

yes

yes

HP/LP Alarm

yes

yes

yes

Liquid injection kit, phase loss/

sequence protection

-

yes

-

Version control

Designation system for the

Optyma

™ Plus range

* Inbuilt function within Condensing unit electronic controller

Instructions

118U3276G - AN18658643414604-001701 | 3

© Danfoss | Climate Solutions | 2022.02

1 – Introduction

These instructions pertain to Opty-

ma

™

Plus condensing units OP-MPYM,

OP-MPXM, OP-MPGM, OP-LPQM, OP-LPOM & OP-

MPBM used for refrigeration systems. They pro-

vide necessary information regarding safety and

proper usage of this product.

The condensing unit includes following:

• Microchannel heat exchanger

• Reciprocating or scroll compressor

• Receiver with stop valve

• Ball valves

• Sight glass

• High & low pressure switches

• Replaceable filter drier

• Electronic controller

• Main circuit breaker (Main switch with overload

protection)

• Fan and compressor capacitors

• Compressor contactor

• Supply monitoring relay**

• Robust weather proof housing

• Liquid injection controller (Module B Plus)*

• Electronic expansion valve (ETS6)*

*Only for P02 version,

**only for P05 models

2 – Handling and storage

• It is recommended not to open the packaging

before the unit is at the final place for installa-

tion.

• Handle the unit with care. The packaging al-

lows for the use of a forklift or pallet jack. Use

appropriate and safe lifting equipment..

• Store and transport the unit in an upright posi-

tion.

• Store the unit between -35°C and 50°C.

• Don’t expose the packaging to rain or corrosive

atmosphere.

• After unpacking, check that the unit is com-

plete and undamaged.

3 – Installation precautions

Never place the unit in a flammable atmos-

phere.

Place the unit in such a way that it is not bloc-

king or hindering walking areas, doors, windows

or similar.

• Ensure adequate space around the unit for air

circulation and to open doors. Refer to picture

1 for minimal values of distance to walls.

• Avoid installing the unit in locations which are

daily exposed to direct sunshine for longer pe-

riods.

• Avoid installing the unit in aggressive and dus-

ty environments.

• Ensure a foundation with horizontal surface

(less than 3° slope), strong and stable enough

to carry the entire unit weight and to eliminate

vibrations and interference.

• The unit ambient temperature may not exceed

50°C during off-cycle.

• Ensure that the power supply corresponds to

the unit characteristics (see nameplate).

• When installing units for HFC refrigerants, use

equipment specifically reserved for HFC refri-

gerants which was never used for CFC or HCFC

refrigerants.

• Use clean and dehydrated refrigeration-grade

copper tubes and silver alloy brazing material.

• Use clean and dehydrated system components.

• The suction piping connected to the compres-

sor must be flexible in 3 dimensions to dampen

vibrations. Furthermore piping has to be done

in such a way that oil return for the compres-

sor is ensured and the risk of liquid slug over in

compressor is eliminated.

4 – Installation

• The installation in which the condensing unit is

installed must comply to pressure Equipment

Directive (PED) 2014/68/EU. The condensing unit