Operating conditions

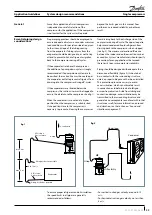

A low pressure (LP) safety switch is

recommended. MLZ/MLM scroll compressors

exhibit high volumetric efficiency and may draw

very low vacuum levels, which could induce scroll

instability and electrical arcing at the internal

cluster. The minimum low-pressure safety switch

setting is given in the above table. For systems

without pump-down, the LP safety switch

must either be a manual lockout device or an

automatic switch wired into an electrical lockout

circuit. The LP switch tolerance must not allow for

vacuum operations of the compressor. LP switch

settings for pump-down cycles with automatic

reset are also listed in the table above.

Low pressure

On/off cycling (cycle rate

limit)

Depending on the application, a number higher

than 12 starts per hour can reduce the service life

of the motor-compressor unit. A one-minute time

out is recommended.

The system must be designed in a way that

provides a minimum compressor running time

of 3 minutes so as to provide for sufficient motor

cooling after start-up along with proper oil

return. Note that the oil return may vary since it

depends upon system design.

Danfoss recommends a restart delay timer to

limit compressor cycling.

R22

R404A

Working pressure range high side

bar (g)

7.1 - 26

9.9 - 27.7

Working pressure range low side

bar (g)

0.7 - 6.2

1.0 - 6.6

Maximum high pressure safety switch setting

bar (g)

27.1

29

Minimum low pressure safety switch setting

bar (g)

0.5

0.7

Recommended pump-down switch settings

1.5 bar below nominal evaporating pressure

Minimum low pressure pump-down switch setting

bar (g)

0.6

0.9

LP safety switch shall never have time delay.

For MLZ/MLZ116, a high pressure switch is

required to shut down the compressor should

the discharge pressure exceed the values shown

in the table above.

The high-pressure switch can be set to lower

values depending on the application and

ambient conditions. The HP switch must either be

placed in a lockout circuit or consist of a manual

reset device to prevent cycling around the

high-pressure limit. If a discharge valve is used,

the HP switch must be connected to the service

valve gauge port, which must not be isolated.

High pressure

High and low pressure

protection

Defrost cycle

In refrigeration system applications, there are

different defrost methods, such as electric

heating defrost, hot gas bypass defrost,

reversible defrost etc. For the system which use

hot gas bypass or reversible defrost method,

suction accumulator is necessary as a result

of the possibility of a substantial quantity of

liquid refrigerant remaining in the evaporator,

this liquid refrigerant can then return to the

compressor, either flooding the sump or as

a dynamic liquid slug when the cycle switch

back to normal cooling operations. Sustained

and repeated liquid slugging and flooding can

seriously impair the oil’s ability to lubricate the

compressor bearings. In such cases a suction

accumulator is a must.

22

FRCC.PC.035.A5.02

Application Guidelines

Single compressors