104

Capacity

controller RS8ER302 © Danfoss 2016-02

AK-CH

650

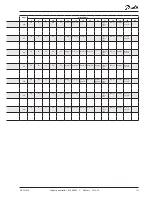

Compressor application 6 – 1 x Speed + unloader

The controller can operate one speed-regulated compressor com-

bined with several capacity-regulated compressors of the same

size and with the same number of unloaders.

The advantage of this combination is that the variable part of the

speed-regulated compressor only needs to be large enough to

cover the following unload valves in order to achieve a capacity

curve without gaps.

Preconditions for using this compressor application are:

• A single speed-regulated compressor that can be of a different

size than the following compressors

• The capacity-regulated compressors are the same size and have

the same number of unload valves (max. 3)

• The main step on the capacity-regulated compressors are the

same size

• The main step and the unload valves can be different sizes, i.e.

50%, 25% and 25%.

This compressor combination can be handled in the following

coupling patterns:

• Sequential

• Cyclical

Handling the speed-regulating compressor.

For further information on the general handling of the speed-

regulated compressor, refer to section "Power pack types".

Cyclical operation - example

The speed-regulated compressor is always the first to start and

last to stop.

The capacity-regulated compressors are cut in and cut out in ac-

cordance with the First-in-First-Out principle in order to equalise

operating hours

The speed-regulated compressor is used to fill the capacity gaps

between the unload valves/main steps.

Increasing capacity:

- The speed-regulated compressor starts when the desired

capacity matches the start speed

- The main step on the capacity-regulated compressor with

fewest operating hours (C1) is cut in when the speed-regulated

compressor runs at full speed (60 Hz)

- The unload valves are cut in gradually as the speed-regulated

compressor again reaches max. speed (60 Hz)

- The main step on the last capacity-regulated compressor (C2)

is cut in when the speed-regulated compressor again reaches

max. speed (60 Hz)

- The unload valves are cut in gradually as the speed-regulated

compressor again reaches max. speed (60 Hz)

- When the main step or unload valves are cut in, the speed is re-

duced on the speed-regulated compressor (35 Hz) is equivalent

to the capacity of the cut in capacity.

Decreasing capacity:

- The capacity-regulated compressor with the most operating

hours (C2) cuts out an unload valve when the speed-regulated

compressor has reached min. speed (25 Hz)

- When the speed-regulated compressor again reaches min.

speed (25 Hz), the unload valve is cut out on the next capacity-

regulated compressor (C3)

- When the speed-regulated compressor again reaches min.

speed (25 Hz), the main step is cut out on the capacity-regulat-

ed compressor with the most operating hours (C2)

- When the speed-regulated compressor again reaches min.

speed (25 Hz), the main step is cut out on the last capacity-

regulated compressor (C3)

- The speed-regulated compressor is the last compressor that is

cut out when the conditions for this are fulfilled

- When the main step or unload valves are cut out, the speed of

the speed-regulated compressor increases (50 Hz) to equiva-

lent to the cut out capacity