D

INSTALLATION

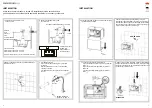

6. Mount unit cabinet to the wall. Insert power cord

through the inlet hole located in the back of the cabinet, or

through the premade opening at the bottom of the cabinet.

Connect power cord to hand dryer. It may be necessary to

remove a plate to push the cord through.

POWER CORD

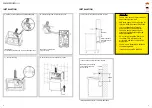

8. Remove end cap from blind plug. Pull wires and earthing

through the flexi hose and air branch on motor. Fasten the

flexi hose to the cabinet branch. Attach the opposite end of

the flexi hose to branch on tap.

BLIND PLUG

INSTALLATION

Make sure the main breaker is turned off. Installation must be carried out by a

qualified person in accordance with applicable standards in the country concerned.

3. Mark the desired postion on the wall and drill a Ø35

mm diameter hole.

4. Installation of the tap:

A) Push the screwed bushing through the hole

in the wall

B) Place gasket, disc, and nut on the threaded

coupling of the tap

C) Tighten with tool, be careful not to overtighten

the nut.

Recommended wall

thickness: 10-30 mm

Gasket

Disc

Nut

5. Unscrew (2) bottom screws and remove cabinet using

the allen wrench included .

1. Check the required distance from

sensor to sink.

30°

Ceramic ≥250 mm

Brushed steel ≥300 mm

Sensor

Sensor field of view:

Object distance 250 mm: D: ≤128 mm

Object distance 300 mm: D: ≤155 mm

Objects within range D may cause unintentional activation.

160

D

2. Check the required distance from

sensor to sink.

Recommended wall thickness: 10-30 mm

19 mm

≥170mm

30°

Sensor

A minimum distance

of 180 mm is

required between

each tap product.

≥180 mm

Distance

from

sensor to

sink:

7. Connect supply wires to terminal block:

A) Connect phase wire (black or brown) to terminal

block ”L”.

B) Connect neutral wire (light blue) to terminal

block ”N”.

C) Connect earthing (yellow/green) to terminal

block ” ”

6

7