6

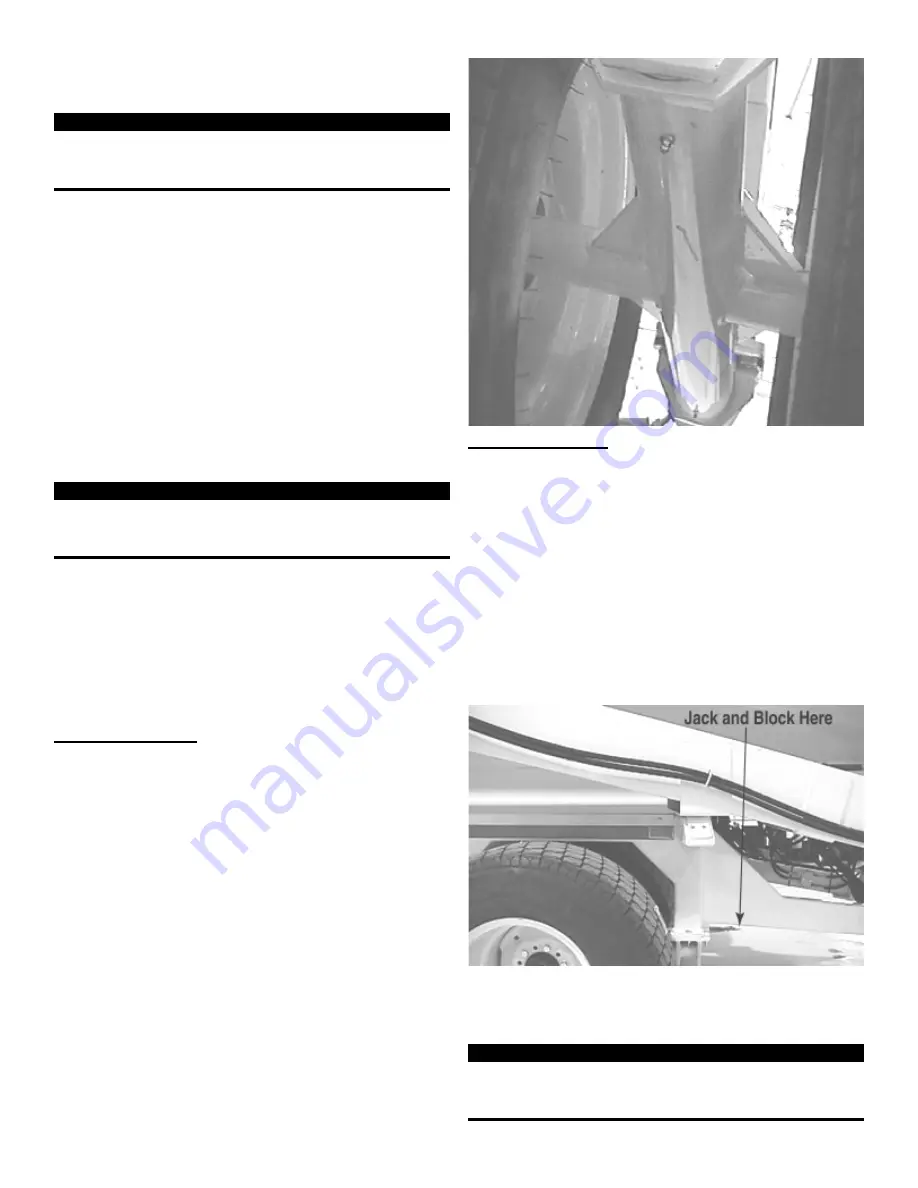

3. Using jack stands, support the frame so it is safe to work

beneath. Under no conditions should cement blocks (cinder

blocks) or unstable piles of wood blocks be used.

WARNING

Do not perform maintenance of any kind below the

Turf Tender unless it is properly secured and

stabilized.

4. Remove the walking beam axle mounting bolts and nuts

(front & rear). Roll axle assembly out to the rear.

5. Stand the axle assembly on end and remove the wheel

bolts; then remove the wheel.

6. Bring the wheel to a tire repair center to fix or replace the

tire.

NOTE: Due to the specialized equipment necessary,

tire removal, repair, and mounting should be only

performed by a tire repair service shop.

7. Place the wheel back into position; then install the wheel

bolts. Tighten until snug.

NOTE: Do not lubricate threads.

8. Using a crisscross pattern, tightening wheel bolts to 90 ft-

lb (12.4 kg-m).

CAUTION

Do not under or over torque the wheel bolts.

Inappropriate wheel bolt torque will result in wheels

loosening and possibly falling off.

9. Roll the axle assembly back under the Turf Tender and

install the eight bolts and nuts securing it to the frame.

Tighten the hardware to 75 ft-lb (10.3 kg-m).

10. Remove the jack stands from beneath the Turf Tender;

then lower the jack.

NOTE: Wheel bolt torque must be checked every

10 hours after mounting a wheel until the bolts

maintain the proper torque.

Axle Lubrication

Larger Turf Tender models come equipped with 2

independent walking beam axles. The walking beam axles need

regular greasing maintenance. There are grease points on the

front and rear of each axle assembly. General lithium grease

may be used for a lubricant. See the lubrication schedule for

proper lubrication application.

Wheel Bearings

The wheel bearings should be repacked with grease and

the seals inspected annually under normal use and conditions.

This procedure should be done more often if you are using the

Turf Tender every day or if working with extremely abrasive

materials or fertilizers.

NOTE: For Turf Tender models with only one wheel

on each side, ignore the steps referencing the

walking beam axles.

1. Empty all material from the hopper; then chock the

wheel(s) on the opposite side of the Turf Tender.

2. With the Turf Tender hooked to a tractor that has the

parking brake set, jack up the frame directly in front of

the axle mount.

3. Using jack stands, support the frame so it is safe to work

beneath. Under no conditions should cement blocks (cinder

blocks) or unstable piles of wood blocks be used.

WARNING

Do not perform maintenance of any kind below the

Turf Tender unless it is properly secured and

stabilized.

MAINTENANCE