370 S 370 S L 370 PP 370 PP L

30

system for the non-ferrous head, using a ferrous cover plate. This plate will need to be modified, adding a discharge tube

connection. (Ref 2)

WARNING!!!!!

ONLY A SLING APPROVED BY OSHA AND THAT IS RATED FOR THIS WEIGHT SHOULD

BE USED.

C. Move all tubing and wiring clear of the head, and CAREFULLY AND SAFELY place a sling or strap around the

head. This sling will be used in lifting the head from the column, so take care in placing this strap.(Figure B ref 3)

Step 3:

Removing the gib plates. (Figure B ref 5/6)

A

. With the head securely strapped, loosen and remove booth head lever cams from the “T” slot in the head. (Ref 4)

B.

Remove the set screw from the lower lock nut on the head feed cylinder piston. (See gib plate detail drawing. ref A)

If this screw and nut are behind an obstruction, remove the upper and lower air lines, from the fittings on the head feed

cylinder. Place a compressed air nozzle in the upper or lower fitting on the cylinder, and move head up or down to

clear obstruction. (Move hoist with the strap to allow movement.)

C

. Remove the lower locking nut from the head feed cylinder piston. (Ref b on gib plate detail drawing)

D

. With the head disconnected from the head feed cylinder, gently lower the head down using the strap and hoist.

Lower until head has cleared the piston.

E

. Eight allen head bolts hold the two gib plates to the head. From the back of the column remove these eight bolts.

(Ref C on gib plate detail drawing) Note: These bolts may be quite tight. An impact wrench may be useful for this.

Note:

Step 6 may need to be repeated to raise or lower the head to allow access to the bolts.

F

. With the eight bolts removed, carefully remove the two gib plates from the machines, and place in a safe location

where no damage will come to them. (Mark left top / right top for future installation)

Step 4:

Removing the head.

A With all tubes, wires, etc. clear from the head, pull the head away from the column, (figure C ref 7) using a strap and

hoist. (Fork lift or engine hoist can be used)

Warning!!!!!

Head may be difficult to balance. Take caution when lifting the head

B Using extreme care set the head in a safe location in an upright position.

REPLACEMENT HEAD INSTALLATION

Installing head onto the column

A

. Wipe all way surfaces clean of debris. Wipe the rear machined surfaces and oil galley rings of the head, clean of

debris.

B

. With the replacement head carefully strapped and hooked to a hoist etc., lift the head to the column, and insert

between ways (figure D).

Note

: When placing the replacement head keep it low on the column, below the cylinder piston threads.

Installing the gib plates

A

. The gib plates that came with this head may need some grinding or adjusting. This procedure is a one time

operation, and will not be needed on future installations.

B

. Bolt the two gib plates to the back of the head in reverse order from above. (Figure E ref 5)

C

. Attempt to wobble these gib plates while on the machine. If they are tight, grasp the head and try to move it side to

side. Watch for gaps at the ways when moving the head side to side.

D

. If there is slight movement, tighten the gib blocks up a half turn at a time. Adjustments are made with the screws

threaded into the top of the gib block, as shown in gib plate detail drawing ref e. (The two rear plates will show gaps

when the head is moved front to back, (Adjust the back gibs) the gib plate on the side will be responsible for side to

side movement. (Adjust these gibs for side to side movement)

Note: Refer to gib block adjustment

.

E After any gib block adjustments are made, the head must be tested for free travel. Using the strap raise and lower the

head on the column and check that the head travels the full length of the column, without binding or jerking. There will be a

Summary of Contents for Euromatic 370 PP

Page 9: ...370 S 370 S L 370 PP 370 PP L 9 ...

Page 10: ...370 S 370 S L 370 PP 370 PP L 10 Actual control panel layout may vari ...

Page 32: ...370 S 370 S L 370 PP 370 PP L 32 ...

Page 33: ...370 S 370 S L 370 PP 370 PP L 33 ...

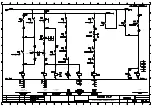

Page 38: ...ALIMENTAZIONE 230V 60Hz 230V 60Hz POWER SUPPLY POWER SUPPLY ...

Page 39: ...HL4 ILLUMINAZIONE LAMA POWER SUPPLY ...

Page 40: ...LAMPEGGIATORE LAMA IN MOTO 24VAC MORSA 24VAC EMERGENCIES ...

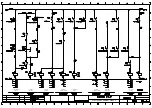

Page 44: ...9 11 2 4 5 10 3 6 7 8 1 CH1 LC4HR424ACJ KA5 RITORNO CARRO COUNTER ...

Page 45: ...TERMINAL ...

Page 49: ...10 2 2019 Euromatic 370 2 Head Cylinder Unit Ref 005 ...

Page 51: ...10 2 2019 Euromatic 370 4 Bedplate Unit Ref 008 ...

Page 53: ...10 2 2019 Euromatic 370 6 Head Unit Ref 002 ...

Page 55: ...10 2 2019 Euromatic 370 8 Vise Unit Ref 004 ...

Page 57: ...10 2 2019 Euromatic 370 10 Group Feeder P R ...

Page 59: ...10 2 2019 Euromatic 370 12 Group Alimentador P P Ref 014b Alimentador Ref 014b ...