O-UC12-FEB23-3

Page 4

Service and Maintenance

A preventative maintenance schedule should be set up as

soon as the Unit Cooler is installed. The unit should be

inspected periodically for proper operation and buildup

of dirt.

1.

Inspect and clean the drain pan to ensure there is

no blockage. The drain pan should be cleaned

regularly with warm water and neutral detergent.

2. The cabinet can be cleaned with water and neutral

detergent. DO NOT clean the fans and fins using a water

jet or high-pressure cleaner.

3. The evaporator coil should be checked once a month for

proper defrosting. Many variables affect coil frosting

such as room temperature, type of product being stored,

how often new product is brought in and the length of

time the door to the room remains open. Summer

conditions of high humidity can cause heavier frost loads.

It may be necessary to change the numbers of defrost

cycles seasonally.

4. At least every six months check all fan motors. Tighten

motor mounting screws and fan set screws.

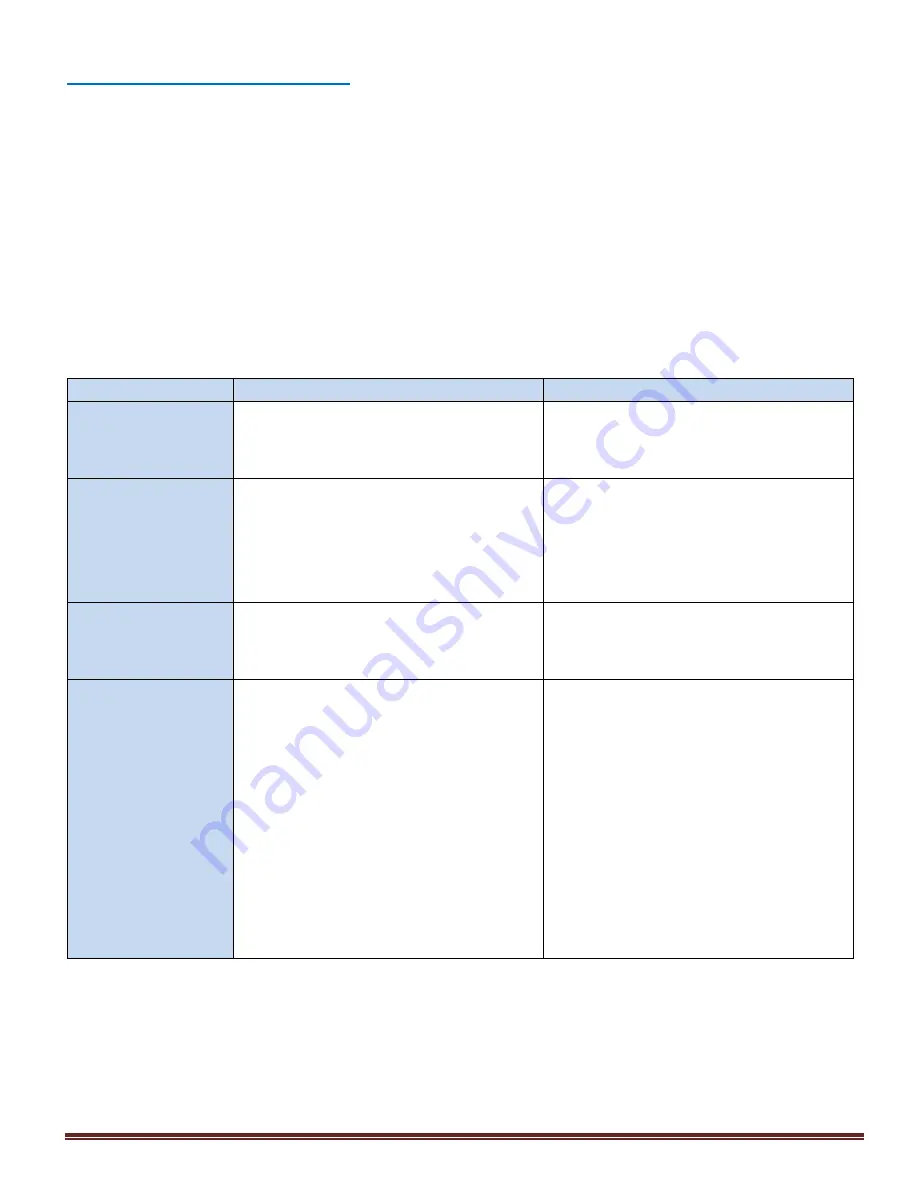

Table 1: Troubleshooting Chart

PROBLEM

POSSIBLE CAUSES

CORRECTIVE ACTION

Excessive buildup of

frost on coil.

•

Defrost time is too short.

•

Extend defrost period on the

temperature controller.

•

Too high humidity in room.

•

Limit access to cold room; do not keep

doors open during stocking.

Accumulation of ice or

water in drain pan.

•

Drain line plugged.

•

Clean drain line. Make sure drain line is

insulated properly.

•

Drainpipe does not have slope angle.

•

Install the drain line with slope.

•

Indoor unit does not install in level at all

directions.

•

Check unit installation and align the unit

level at all directions.

•

Drain line does not have drain trap.

•

Install drain line trap.

Noise

•

· Resonance on the vibrating

mounting parts.

•

Fix the position of vibrating part

correctly.

•

Vibration of fan or fan mounting

misaligned.

•

Fix the position of fan correctly; replace

if defective.

Room temperature too

high (not cold)

•

Incorrect setting on the temperature

controller.

•

Correct the temperature controller

setting.

•

The compressor stopped by alarms

triggered on the controller.

•

Check the type of error, fix the error

and replace the defective parts if any.

•

Incorrect sensor temperature.

•

Check the room temperature sensor

location. Ensure it was not affected by

other sources.

•

Insufficient

refrigerant

flow

to

evaporator.

•

Check for any refrigerant leakage or

choking on expansion valve. Repair the

fault and charge system if necessary.

•

Thick frost built on evaporator coil.

•

Defrost the coil and clean the frost.

•

Too frequent defrosting.

•

Reduce defrost cycle frequency.

•

Incorrect matching of indoor capacity to

outdoor.

•

Review

and

reselect

the

unit

combination.