SiENBE28-901

Test Operation

Air Cooled Refrigeration Condensing Unit

67

Caution

Conduct an airtight test and vacuum drying precisely through the service ports of both liquid

and gas shutoff valves.

Use charge hoses (provided with a pushing rod each) when using the service ports.

In case of possible water intrusion into piping

Perform the above mentioned vacuum drying for 2 hours first in the following cases:

The product is installed in the rainy season, there is a fear of dew condensation resulting in the

piping because the installation work period is long, or there is a fear of rainwater intrusion into

the piping for other reasons.

Then

impose a pressure of up to 0.05 MPa

with nitrogen gas (for vacuum destruction) and

vacuum the unit down to –100.7 kPa or below for 1 hour with a vacuum pump

(for vacuum

drying).

Repeat vacuum destruction and vacuum drying if the pressure does not reach –100.7 kPa or

below after a minimum of 2 hours’ vacuuming. Leave the vacuum state for 1 hour then, and

check that the vacuum gauge reading will not rise.

5.3.2 Thermal Insulation Work

Be sure to perform thermal insulation of the piping after the airtight test and vacuum drying.

Be sure to perform the thermal insulation of the liquid and gas pipes in the connecting piping.

Otherwise, water leakage may result.

Be sure to insulate liquid and gas connection piping. Failure to do so may result in water

leakage. Consult the following chart as a general guide when selecting the insulation

thickness.

Liquid pipe arrival minimum temperature –10°C

Gas pipe arrival minimum temperature

–20°C (MT (Medium Temperature))

–40°C (LT (Low Temperature))

Reinforce the insulation material for the refrigerant piping according to the environment of

thermal installation. Otherwise, the surface of the insulation material may result in dew

condensation.

If the dew condensation water on the shutoff valves is likely to flow to the indoor unit side

through the clearance between the insulation material and piping because the outdoor unit is

installed above the indoor unit or for some other reasons, perform appropriate treatment

such as the caulking of the joints (see the illustrations below).

Attach the cover of the piping outlet with a knock hole opened. If there is a feature of small

animals intruding through the piping outlet, cover the piping outlet with a blocking material

(field supply) on completion of the steps of “

5.5 Additional Refrigerant Charge

” (see the

illustrations below).

Use the piping outlet for jobs required during the steps of “

5.5 Additional Refrigerant

Charge

” (e.g., a job of taking in the charge hose).

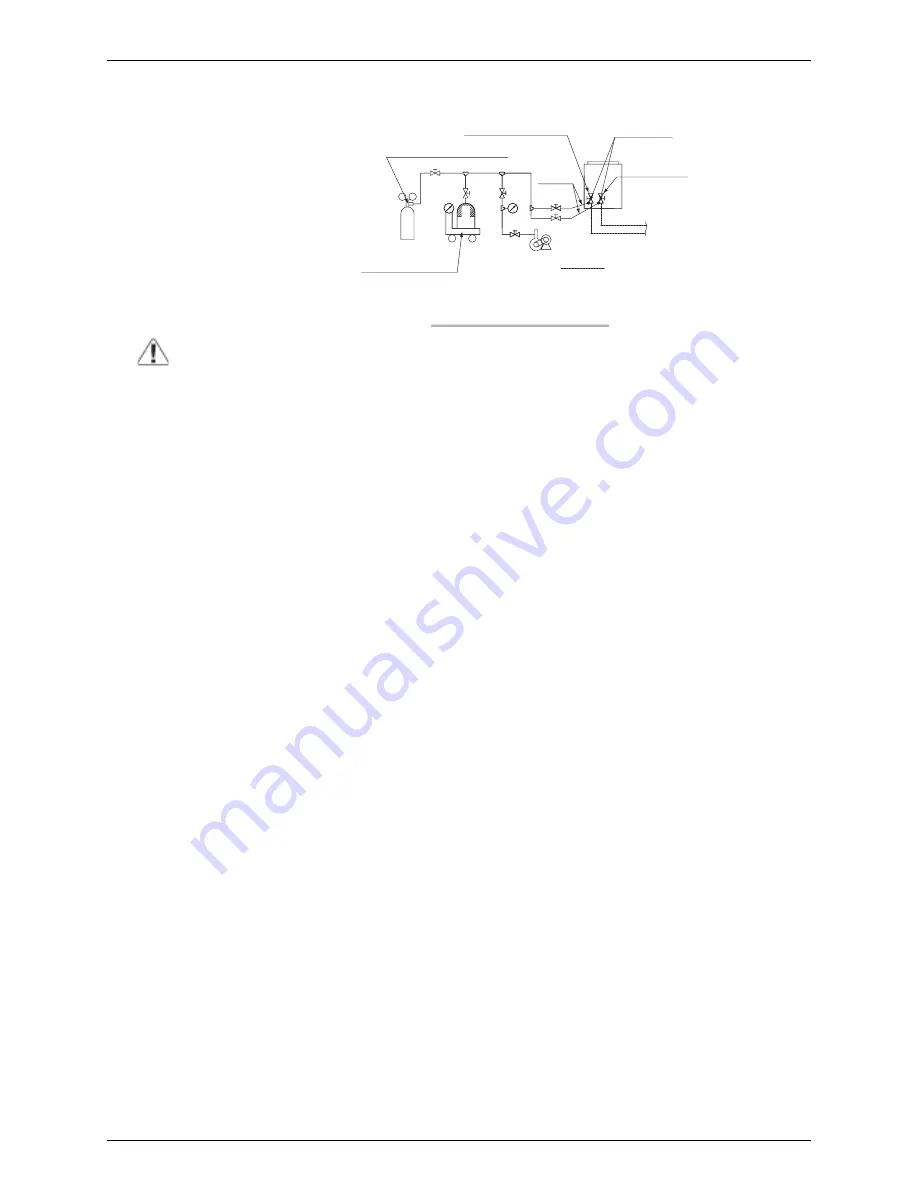

Gas side shutoff valve

Pressure-reducing valve

Charge

hose

(w

ith s

ipho

n)

Valve

R410A

Tan

k

Nit

rog

en

Used for refrigerant

replenishment

Meter

Connection procedure for gauge

manifold and vacuum pump

Note:

Field pipings

Vacuum pump

Shutoff valve

service port

Liquid side

shutoff valve

Outdoor unit

To indoor

unit