SiENBE28-901

Troubleshooting

Air Cooled Refrigeration Condensing Unit

137

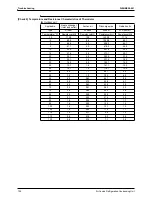

[Check 8] List of Malfunction Codes Related to Inverter

Code

Name

Condition for determining malfunction

Major faulty point

Compressor current

L5

INV Compressor

Instantaneous Overcurrent

Inverter output causes an overcurrent

to flow even instantaneously.

Inverter getting caught in liquid

Faulty compressor

Faulty inverter PCB

L8

Overcurrent of INV

compressor (electronic

thermal)

The compressor performs overload

operation.

Loss of synchronization is detected.

Liquid back of compressor

Sharp change in load

Disconnection of compressor wiring

Faulty inverter PCB

Protecti

on devi

ce, etc.

L1

Faulty Inverter PCB

No output is produced.

Faulty heavy current part of inverter

L9

Faulty INV Compressor

Startup

The compressor motor fails to start

up.

Inverter getting caught in liquid or

faulty compressor

Excessive oil or refrigerant

Faulty inverter PCB

E5

Inverter Compressor Lock

The compressor is in locked state

(does not rotate).

Faulty compressor

L4

Rise in Radiation Fin

Temperature

The radiation fin temperature

exceeds the reference value (while in

operation).

Malfunction of fan

Long-term overload operation

Faulty inverter PCB

U2

Abnormal Power Supply

Voltage

The inverter power supply voltage is

high or low.

Abnormal power supply

Faulty inverter PCB

P1

Power Supply Imbalance

The three-phase power supply has a

significant voltage imbalance.

Abnormal power supply (Power

supply imbalance of not less than 2%)

Faulty inverter PCB

End of PCB service life

LC

Malfunction Related to

Transmission (between

Main PCB and Control

PCB)

The outdoor unit PCB cannot make

communications among the control

PCB, inverter PCB, and fan PCB.

Broken wire in communication line

Faulty control PCB

Faulty inverter PCB

Faulty fan PCB

P4

Faulty fin thermistor

The fin thermistor gets short-circuited

or open.

Faulty fin thermistor