English

10

CAUTION

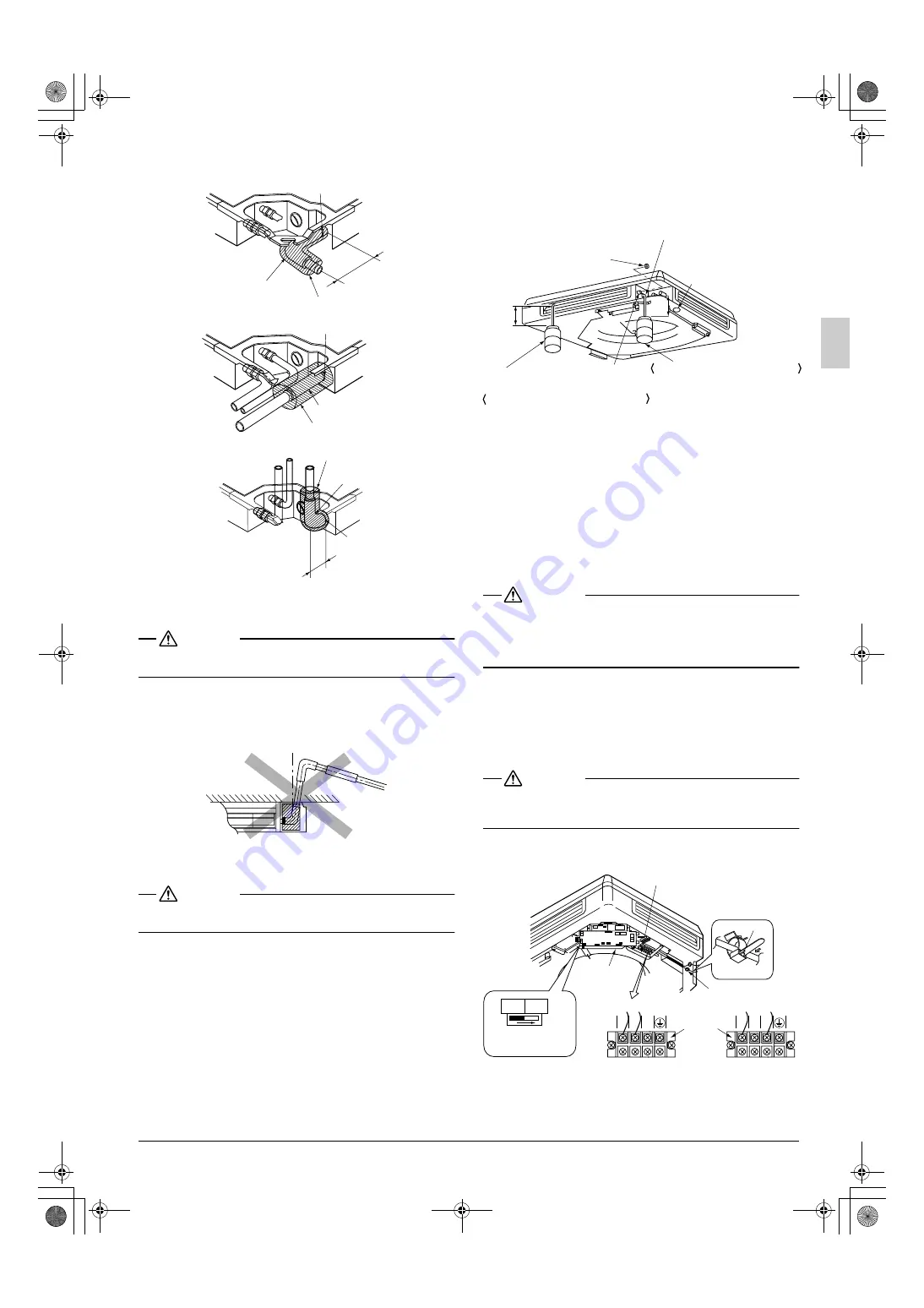

• Do not twist or bend the drain hose (1), so that exces-

sive force is not applied to it, as this could cause leaks.

PRECAUTIONS FOR UPWARD DRAIN RAISING PIPING

• Install the drain raising pipes at a height of less than

500mm.

• Install the drain raising pipes at a right angle to the

indoor unit.

(Refer to Fig. 29)

CAUTION

If the upward running drain hose leans at a slant, the float

switch will malfunction and water will leak.

7-2 After piping work is finished, check if drainage

flows smoothly.

• Open the water inlet lid, add approximately 1000cc of

water slowly and check drainage flow.

(Refer to Fig. 30)

[Caution]

Drain piping connections

• Do not connect the drain piping directly to sewage pipes that

smell of ammonia. The ammonia in the sewage might enter

the indoor unit through the drain pipes and corrode the heat

exchanger.

WHEN ELECTRIC WIRING WORK IS FINISHED

• Check drainage flow during Cooling operation, explained

under “TEST OPERATION”.

WHEN ELECTRIC WIRING WORK IS NOT FINISHED

CAUTION

• Electrical wiring work should be done by a certified electri-

cian.

• If someone who does not have the proper qualifications per-

forms the work, perform the following after the test run is

complete.

• Remove the control box lid and change the emergency

switch above the PC board assembly of the indoor unit from

“NORM.” to “EMERG.”. Connect the single-phase power

supply and earth wire to the power supply (50Hz 220-240V)

terminal board and confirm drain operation.

Be sure to change the switch before turning on the power.

(Refer to Fig. 31)

CAUTION

• Clamp solidly to clamp C to make sure no excess pressure

is applied to the wiring connections.

• Be aware that the fan will turn during the operation.

• After confirming drainage, turn off the power and be sure to

change the emergency switch back to “NORM.”.

Clamp (2)

Clamp (2)

Clamp (2)

Sealing pad (8)

Sealing pad (8)

Sealing pad (8)

Elbow (9)

Drain hose (1)

Short end

Upward

running

pipe

Elbow (9)

Fig. 28

Long

end

WRONG

Fig. 29

Service cover

≥

100

≥

100

Plastic watering can

(Tube should be about 100mm long.)

Inspection opening

Service drain outlet

(with rubber plug).

(Use this outlet to drain water

from the drain pan.)

Drain pipe

Method of adding water

Fig. 30

Adding water through air discharge outlet

Adding water from inspection opening

Power supply terminal board

Indoor PC

board

assembly

Single phase power supply

Fig. 31

Clamp C

Tab

1 2 3

Power

supply

terminal

board

1 2 3

(FUQ model)

(Other models)

NORM. EMERG.

Emergency switch

(Normal, Emergency)

Clamp C

01_EN_3P249378-5G.fm Page 10 Friday, January 20, 2012 2:01 PM