【INSTRUCTION MANUAL】

DAIKIN INDUSTRIES, LTD

.

SE-04430

Att.2

[Attached document

A

]

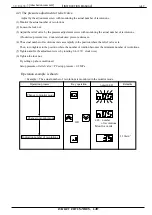

①

To remove the valve block.

1)

Remove the pipe of the P (discharge) port which is mounted on the valve block.

2)

Extract the hose from the radiator to the valve block to take off white hose band from hose fitting (2).

3)

when taking off the white hose band (1), be careful that hydraulic oil sometimes spills from the hose and

the hose fitting (2) both sides,

(The white hose band (1) can be removed by the special driver and so on.)

4)

Cover a small vinyl bag on both ends, in order not to make the body dirty with hydraulic oil from the hose

and

hose fitting (2).

5)

Take off the harness connector bound with the pressure sensor (3).

(Pull out directly below with pushing the locking arm of the connector. Refer to right figure)

6)

Loosen and extract four hexagon socket head cap screws which tightening the valve block, take off the

valve block quietly.

(In this time, hydraulic oil leaks out of the block and the

pump housing.

Wipe out the oil which leaked out with waste cloth and so on.)

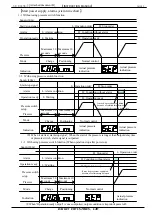

②

Mounts a new valve block.

1)

Confirm that the indication of the setup value marking

point (5) is the pressure of the purpose.

(Example)

When setup pressure is 1.5 MPa, it marks “15”

in case of 7.0 Mpa, it marks “70”.

2)

Confirm that “O” ring is attached to two holes at the bottom

of the valve block.

3)

Wipe both contact surface of the pump housing and the

valve block, with clean cloth.

4)

Be careful not to drop the “O” ring at the bottom of

the valve block, and mounting on the pump housing surface

to the valve block at position indicated figure, and hole

position is put together.

5)

Pass four hexagon socket head cap screws through their bolt mounting holes, and fastened by the

regular torque.

Tightening torque is 12.6

±

1.26N

・

m (129

±

12.9 kgf

・

cm)

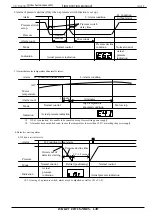

③

Return each wiring and piping to the original position.

1)

Install the pressure sensor harness connector removed above clause

①

on the pressure sensor (3).

(In case of installation, insert the locking arm to the hanger of pressure sensor connector, and then, confirm

that it is locked securely.)

2)

Wipe out hydraulic oil inside the tip of the hose with waste cloth and so on.

3)

Pass white hose band (1) through the hose, and connected with the hose fitting (2).

At this time, make sure to insert a hose into the inner part of hose fitting.

4)

Tighten white hose band (1) in the fixed position of the hose fitting (2).

(Refer to bottom figure of the former page.)

Locking arm

Hanger of

pressure

sensor

connector

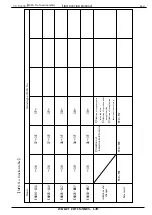

1-1) Change points of the valve block