5

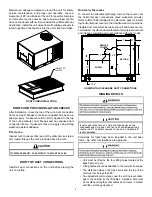

Maintain an adequate clearance around the unit for safety,

service, maintenance, and proper unit operation. Leave a

clearance of 48” on all sides of the unit for possible compres-

sor removal or service access, and to ensure proper ventila-

tion and condenser airflow. Do not install the unit Beneath any

obstruction. Install the unit away from all building exhausts to

inhibit ingestion of exhaust air into the unit’s fresh-air intake.

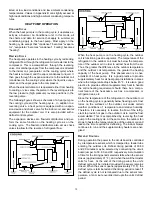

ROOF CURB INSTALLATION

ROOF CURB POST-INSTALLATION CHECKS

After installation, check the top of the curb, duct connection

frame and duct flanges to make sure gasket has been ap

-

plied properly. Gasket should be firmly applied to the top

of the curb perimeter, duct flanges and any exposed duct

connection frame. If gasket is loose, re-apply using strong

weather resistant adhesive.

P

rOtrusiOn

Inspect curb to ensure that none of the utility services (elec-

tric) routed through the curb protrude above the curb.

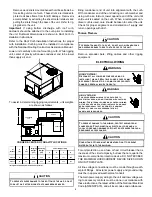

ROOF TOP DUCT CONNECTIONS

Install all duct connections on the unit before placing the

unit on rooftop.

INSULATED

PANELS

I

F

PROTRUSIONS

EXIST

,

DO

NO

ATTEMPT

TO

SET

UNIT

ON

CURB

.

CAUTION

h

OrizOntal

d

isCharge

To convert to horizontal discharge, remove the covers over

the horizontal duct connections (save washered screws).

Refer to IOD-7006 included in the literature pack for install-

ing horizontal duct covers to the downflow duct connections.

Flexible duct connectors between the unit and ducts are rec-

ommended. Insulate and weatherproof all external ductwork

and joints as required and in accordance with local codes.

HORIZONTAL DISCHARGE DUCT CONNECTIONS

RIGGING DETAILS

Provisions for forks have been included in the unit base

frame. No other fork locations are approved.

• Unit must be lifted by the four lifting holes located at the

base frame corners.

• Lifting cables should be attached to the unit with shackles.

• The distance between the crane hook and the top of the

unit must not be less than 60”.

• Two spreader bars must span over the unit to prevent dam-

age to the cabinet by the lift cables. Spreader bars must

be of sufficient length so that cables do not come in contact

with the unit during transport.

RETURN

SUPPLY

12”

17”

7 3/8”

11”

4 7/8””

25”

6 3/16”

REMOVE

COVERS

I

F

UNITS

ARE

LIFTED

TWO

AT

A

TIME

,

THE

FORK

HOLES

ON

THE

CONDENSER

END

OF

THE

UNIT

MUST

NOT

BE

USED

. M

INIMUM

FORK

LENGTH

IS

42”

TO

PREVENT

DAMAGE

TO

THE

UNIT

;

HOWEVER

, 48”

IS

RECOMMENDED

.

CAUTION