6

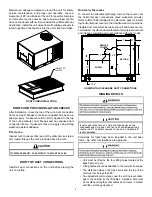

Remove wood struts mounted beneath unit base frame be-

fore setting unit on roof curb. These struts are intended to

protect unit base frame from fork lift damage. Removal is

accomplished by extracting the sheet metal retainers and

pulling the struts through the base of the unit. Refer to rig-

ging label on the unit.

Important:

If using bottom discharge with roof curb,

ductwork should be attached to the curb prior to installing

the unit. Ductwork dimensions are shown in Roof Curb In-

stallation Instructions.

Refer to the Roof Curb Installation Instructions for proper

curb installation. Curbing must be installed in compliance

with the National Roofing Contractors Association Manual.

Lower unit carefully onto roof mounting curb. While rigging

unit, center of gravity will cause condenser end to be lower

than supply air end.

To assist in determining rigging requirements, unit weights

are shown as follows:

CORNER & CENTER OF GRAVITY LOCATIONS

A

B

C

D

CG

SUPPLY

RETURN

EVAPORATOR COIL

CONDENSER

COIL

COMPRESSOR

Y

X

A

B

C

D

DCC072*

35

27

650

625

147

185

127

166

DCH072*

34

28

660

635

142

200

122

171

Corner Weights (lbs)

* Weights shown are belt drive with no accessories

A*

Model

X

(in)

Y

(in)

Shipping

Weight

(lbs.)

Operating

Weight

(lbs)

T

O

PREVENT

SEVERE

DAMAGE

TO

THE

BOTTOM

OF

THE

UNIT

,

DO

NOT

FORK

LIFT

UNIT

AFTER

WOOD

STRUTS

HAVE

BEEN

REMOVED

.

CAUTION

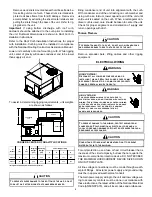

Bring condenser end of unit into alignment with the curb.

With condenser end of the unit resting on curb member and

using curb as a fulcrum, lower opposite end of the unit until

entire unit is seated on the curb. When a rectangular can-

tilever curb is used, care should be taken to center the unit.

Check for proper alignment and orientation of supply and

return openings with duct.

r

igging

r

emOval

Remove spreader bars, lifting cables and other rigging

equipment.

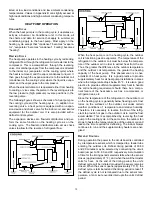

ELECTRICAL WIRING

For unit protection, use a fuse or hacr circuit breaker that is

in excess of the circuit ampacity, but less than or equal to the

maximum overcurrent protection device. DO NOT EXCEED

THE MAXIMUM OVERCURRENT DEVICE SIZE SHOWN

ON UNIT DATA PLATE.

All line voltage connections must be made through weath-

erproof fittings. All exterior power supply and ground wiring

must be in approved weatherproof conduit.

The main power supply wiring to the unit and low voltage wir-

ing to accessory controls must be done in accordance with

these instructions, the latest edition of the National Electrical

Code (ANSI/NFPA 70), and all local codes and ordinances.

T

O

PREVENT

DAMAGE

TO

THE

UNIT

,

DO

NOT

ALLOW

CRANE

HOOKS

AND

SPREADER

BARS

TO

REST

ON

THE

ROOF

OF

THE

UNIT

.

CAUTION

HIGH VOLTAGE!

D

ISCONNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

THIS

UNIT

. M

ULTIPLE

POWER

SOURCES

MAY

BE

PRESENT

. F

AILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

.

WARNING

HIGH VOLTAGE!

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DO

NOT

TAMPER

WITH

FACTORY

WIRING

. T

HE

INTERNAL

POWER

AND

CONTROL

WIRING

OF

THESE

UNITS

ARE

FACTORY

-

INSTALLED

AND

HAVE

BEEN

THOROUGHLY

TESTED

PRIOR

TO

SHIPMENT

.

C

ONTACT

YOUR

LOCAL

REPRESENTATIVE

IF

ASSISTANCE

IS

REQUIRED

.

WARNING

T

O

PREVENT

DAMAGE

TO

THE

WIRING

,

PROTECT

WIRING

FROM

SHARP

EDGES

. F

OLLOW

NATIONAL

ELECTRICAL

CODE

AND

ALL

LOCAL

CODES

AND

ORDINANCES

. D

O

NOT

ROUTE

WIRES

THROUGH

REMOVABLE

ACCESS

PANELS

.

CAUTION

C

ONDUIT

AND

FITTINGS

MUST

BE

WEATHER

-

TIGHT

TO

PREVENT

WATER

ENTRY

INTO

THE

BUILDING

.

CAUTION