11

b

earing

C

heCk

Prior to energizing any fans, check and make sure that all

setscrews are tight so that bearings are properly secured

to shafts.

For heat pump units, the airflow must be adjusted so that

the air temperature rise falls within the ranges given stated

on Data Plate (see Appendix A - Blower Performance).

s

et

e

vaPOratOr

f

an

r

Pm

Actual RPM’s must be set and verified with a tachometer or

strobe light. Refer to Appendices A and B for basic unit fan

RPM. Refer also to “Airflow” section of this manual. With

disconnect switch open, disconnect thermostat wires from

terminals Y and W. This will prevent heating and mechan-

ical cooling from coming on. Place a jumper wire across

terminals R and G at TB1 terminal block. Close disconnect

switch; evaporator fan motor will operate so RPM can be

checked.

t

ensiOn

and

a

lignment

a

djustment

Correct belt tension is very important to the life of your belt.

Too loose a belt will shorten its life; too tight, premature mo-

tor and bearing failure will occur. Check you belt drive for

adequate “run-in” belt tension by measuring the force re-

quired to deflect the belt at the midpoint of the span length.

Belt tension force can be measured using a belt tension

gauge, available through most belt drive manufacturers.

*Apply force to the center of the span.

t = Span length, inches

C = Center distance, inches

D = Larger sheave diameter, inches

d = Smaller sheave diameter, inches

h = Deflection height, inches

DRIVE BELT TENSION ADJUSTMENT

RECOMMENDED POUNDS OF FORCE PER BELT

SPAN LENGTH t

*DEFLECTION

FORCE

h

C

d

H

D

BELT

DRIVE

Used

New

A, AX Standard

3.0 to 4.0

4.2 ± .5 5.5 ± .5

0.313

DEFLECTION

(in)

DEFLECTION

FORCE (lbs)

SHEAVE

DIAMETER

(in)

TYPE

New V-belts will drop rapidly during the first few hours of

use. Check tension frequently during the first 24 hours of

operation. Tension should fall between the minimum and

maximum force. To determine the deflection distance from

a normal position, measure the distance from sheave to

sheave using a straightedge or a cord. This is your refer-

ence line. On multiple belt drives, an adjacent undeflected

belt can be used as a reference.

MOTOR SHEAVE ADJUSTMENTS

v

l

, v

m

, & 2

vP

v

ariable

P

itCh

k

ey

t

yPe

m

OtOr

s

heaves

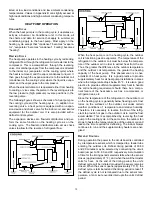

The driving and driven motor sheaves should be in align-

ment with each other and the shafts parallel.

v

l

& v

m

s

heaves

a

djustment

1. Loosen set screw “B” using a 5/32” Allen key.

2. Making half or full turns from closed position, adjust

sheave pitch diameter for desired speed. DO NOT OPEN

MORE THAN FIVE FULL TURNS.

3. Tighten set screw “B” securely over flat.

4. Carefully put on belts and adjust belt tension. DO NOT

FORCE BELTS OVER GROOVES.

5. Ensure all keys are in place and the set screws tight be-

fore starting drive. Recheck set screws and belt tension

after 24 hours service.

NOTE:

Future adjustments should be made by loosening

the belt tension and increasing or decreasing the pitch di-

ameter of the sheave by half or full turns as required. Read-

just belt tension before starting drive.

SHEAVE DIAGRAM

NOTE:

Do not operate sheave with flange projecting be

-

yond the hub end.

r

efrigeratiOn

s

ystem

C

heCks

Ensure the hold-down bolts on the compressor are secure

and have not vibrated loose during shipment. Check that

the vibration grommets have been installed and visually

check all piping for damage and leaks and repair if nec-

essary. The entire system has been factory charged and

tested, making it unnecessary to field charge. Factory re

-

frigerant charge is shown on the unit’s nameplate.

C

B

VL & VM