4 Installation

Installation manual

6

C08AA

Daikin hybrid for multi heat pump – heat pump module

4P471756-1C – 2017.10

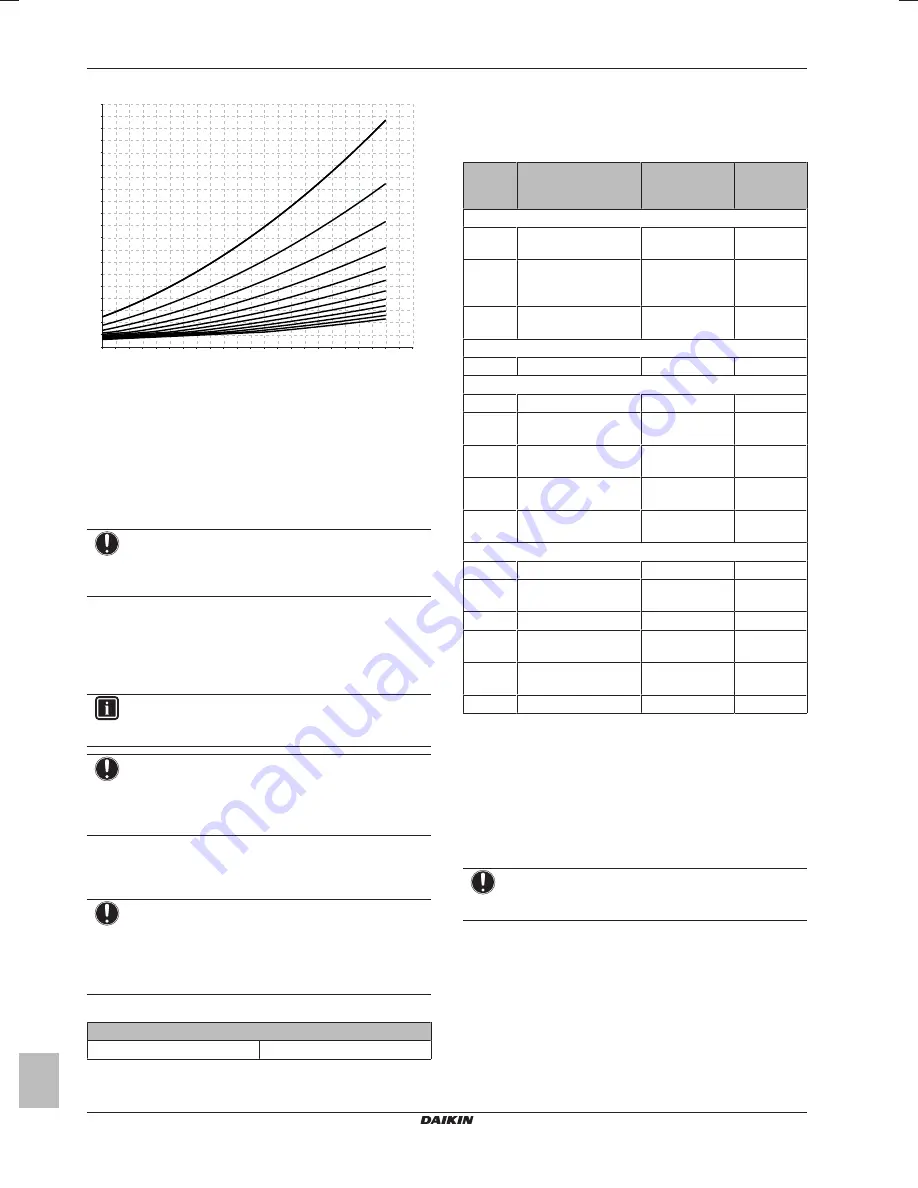

B (kg)

A (m

2

)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5

H=500, 600, 700 mm

H=800 mm

H=1000 mm

H=900 mm

H=1100 mm

H=1200 mm

H=1300 mm

H=1400 mm

H=1500 mm

H=1600 mm

H=1700 mm

H=1800 mm

A

Minimum floor area for hybrid unit (m

2

)

B

Total refrigerant charge in the system (kg)

H

The height measured from the floor to the bottom of the

casing. The graph is based on the height measured from

the floor to the flare nut.

▪ The indoor unit is designed for indoor installation only (in a

technical room or similar) and for ambient temperatures ranging

5~30°C in heating mode.

3.2

Preparing water piping

NOTICE

In case of plastic pipes, make sure they are fully oxygen

diffusion tight according to DIN 4726. The diffusion of

oxygen into the piping can lead to excessive corrosion.

3.2.1

To check the water volume and flow rate

Minimum water volume

Check that the total water volume in the installation is minimum

13.5 litre, the internal water volume of the indoor unit NOT included.

INFORMATION

In critical processes, or in rooms with a high heat load,

extra water might be required.

NOTICE

When circulation in each space heating/cooling loop is

controlled by remotely controlled valves, it is important that

the minimum water volume is guaranteed, even if all of the

valves are closed.

Minimum flow rate

Check that the minimum flow rate (required during defrost/backup

heater operation) in the installation is guaranteed in all conditions.

NOTICE

When circulation in each or certain space heating loops is

controlled by remotely controlled valves, it is important that

the minimum flow rate is guaranteed, even if all valves are

closed. In case the minimum flow rate cannot be reached,

a flow error 7H will be generated (no heating or operation).

See the installer reference guide for more information.

Minimum required flow rate

05+08 models

9 l/min

See the recommended procedure as described in

"6.2 Checklist

during commissioning" on page 20

.

3.3

Preparing electrical wiring

3.3.1

Overview of electrical connections for

external and internal actuators

Item

Description

Wires

Maximum

running

current

Outdoor unit and indoor unit power supply

1

Power supply for

outdoor unit

2+GND

(a)

2

Power supply and

interconnection cable to

indoor unit

3+GND

(g)

3

Power supply gas

boiler

2+GND

(c)

User interface

4

User interface

2

(f)

Optional equipment

5

3‑way valve

3

100 mA

(b)

6

Domestic hot water

tank thermistor

2

(d)

7

Room thermostat/heat

pump convector

3 or 4

100 mA

(b)

8

Outdoor ambient

temperature sensor

2

(b)

9

Indoor ambient

temperature sensor

2

(b)

Field supplied components

10

Shut-off valve

2

100 mA

(b)

11

Domestic hot water

pump

2

(b)

12

Alarm output

2

(b)

13

Changeover to external

heat source control

2

(b)

14

Space heat operation

control

2

(b)

15

Safety thermostat

2

(e)

(a)

Refer to name plate on outdoor unit.

(b)

Minimum cable section 0.75 mm².

(c)

Use the cable supplied with the boiler.

(d)

The thermistor and connection wire (12 m) are delivered

with the domestic hot water tank.

(e)

Cable section 0.75 mm² till 1.25 mm²; maximum length:

50 m. Voltage-free contact shall ensure the minimum

applicable load of 15 V DC, 10 mA.

(f)

Cable section 0.75 mm² till 1.25 mm²; maximum length:

500 m. Applicable for both single user interface and dual

user interface connection.

(g)

Cable section 1.5 mm

2

; maximum length: 50 m.

NOTICE

More technical specifications of the different connections

are indicated on the inside of the indoor unit.

4

Installation

4.1

Opening the units

4.1.1

To open the switch box cover of the

indoor unit

1

Remove the side panel at the right side of the indoor unit. The

side panel is fixed at the bottom with 1 screw.