IM 817-4

Page 29 of 60

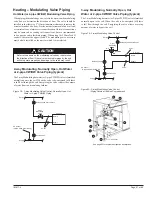

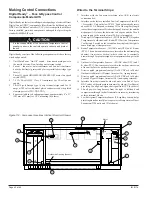

Ensure refrigerant pressure taps are installed in piping end

compartment for proper charging and setting of the TXV

valve.

1-3/8" Left End

of unit

(Less end panel)

Thermal Expansion

Valve (TXV)

Superheat Adjustment.

Return (Suction Line)

Bulb

attached in the 2 or

10 o'clock position

Equalization Tube

Condensate Drain (Protect Drain Pan with

a quenching cloth when brazing, to prevent

damage).

Supply (Liquid Line)

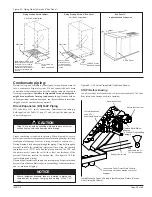

Direct-Expansion (DX) R-22 Piping

DX coils have O.D. sweat connections. Interconnecting tubing is

field-supplied. See Table 21, page 31 and job-specific drawings for

correct tubing sizes.

Wrap TXV valve with a quenching cloth and remove bulb from

suction line to avoid valve damage while brazing.

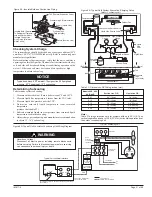

Condensate piping:

Daikin cooling unit ventilators are designed for condensate removal

into a condensate disposal system. Do not connect the unit drain

connection so that condensate exits to the outside and/or is exposed to

freezing temperatures.

Installer is responsible for any damage that

might be caused from freezing condensate

. In applications with an

end compartment auxiliary drain pan, see the installation instructions

shipped with the auxiliary drain pan itself.

STOP! Before Brazing

Remove Bulb When

Brazing

To Prevent Overheating

Damage

Use A Quenching Cloth When Brazing, to Prevent Overheating The TXV Valve

Body (Avoid Valve Damage and Erratic Operation)

Figure 86 - TXV Valve Piping Detail (Left Hand Shown)

Proper ventilation is required for brazing. When brazing, be sure to

protect unit ventilator components from overheating damage (melting

insulation, also damage to valves, wiring, electronics, sensors, etc.).

During brazing, bleed nitrogen through the piping. Using field-supplied

material suitable for insulating refrigerant lines, wrap the thermal

expansion valve (TXV) bulb and the piping between the TXV and

the point where it enters the coil with at least one thickness of the

material. Likewise, insulate the suction line. (See figures 87-90 for

typical piping and wiring)

Ensure proper insulation of supply and return piping. Proper insulation

prevents loss of unit ventilator capacity, overheating of end compartment,

and / or moisture dripping.

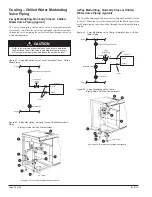

Piping Stub-up Within Cabinet

Unit End Compartment

Piping Stub-up Within 6" End Panel

End Panel 6"

Application and Dimension

Wall Line

1"

11

5

⁄

8

"

10"

Note:

Space available in left

end compartment for piping

stub-up. Stub-up, including

unions and shutoff valves,

must

disconnect below floor

line for unit installation and

removal.

Space available

at left end of unit

for piping stub-up

when 6" end panel

is used.

Left End of unit

(Less end panel)

Wall Line

4"

1"

Unit End Compartment

6"

Figure 85 - Piping Stub-Up Details, 6" End Panel

Install Pressure Taps on Supply (Liquid Line) and Return (Suction

Line) Piping (By Others).

6" End Panel

CAUTION

NOTICE