40

Maintenance

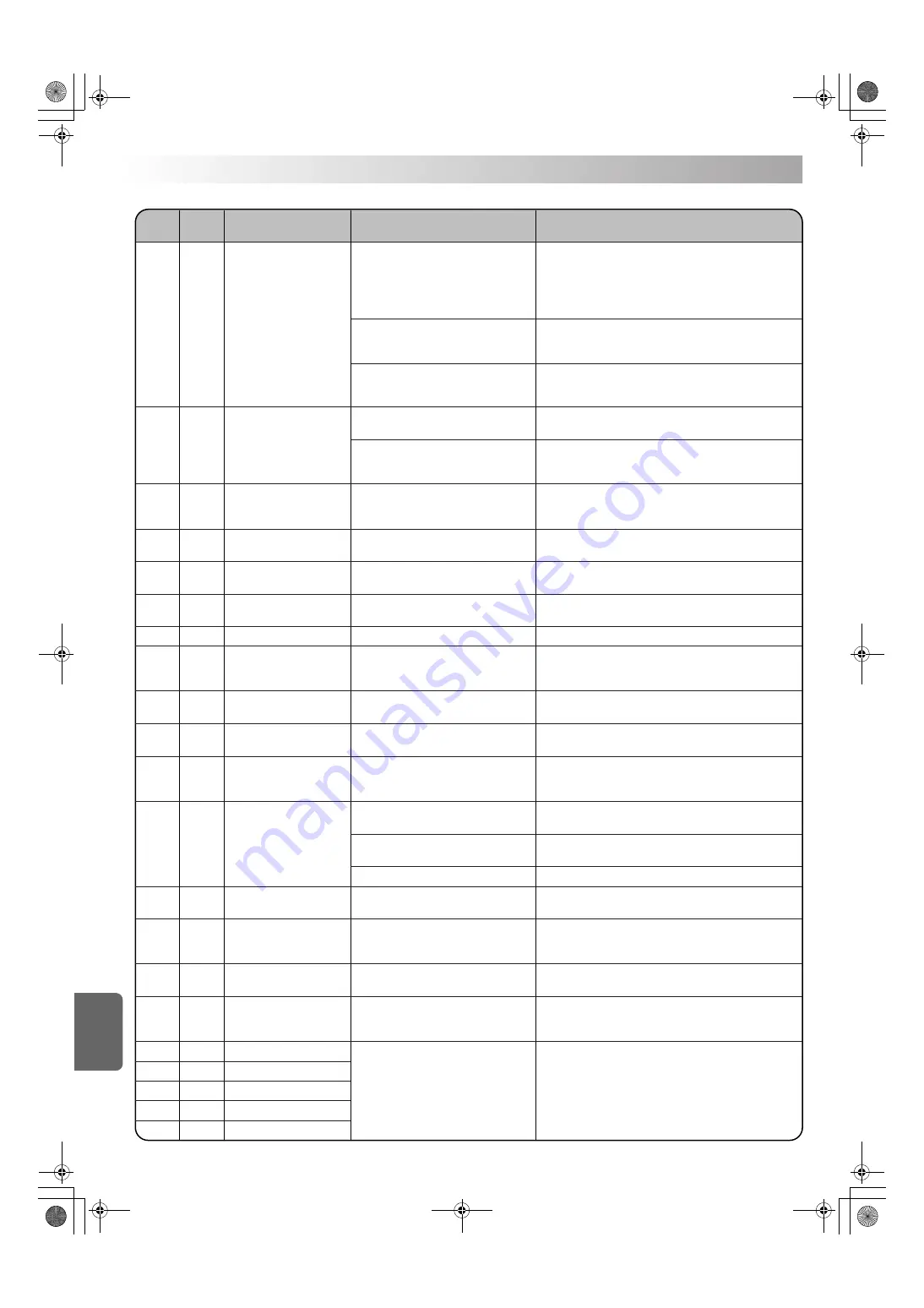

Tr

oub

leshooting

Alarm

code

Alarm

level

Description

Cause

Corrective action

Pump outlet oil temperature

thermistor error

Oil temperature thermistor error

(Th2: Outlet oil temperature thermistor)

(Th4: Inlet oil temperature thermistor)

Discharge pipe temperature

thermistor error

EV valve outlet temperature

thermistor error

Condenser temperature

thermistor error

Inverter/compressor error

INV-temperature control CPU

communication error

Electrical equipment box

temperature thermistor error

Radiator fin temperature

thermistor error

Gas shortage

Power supply reverse-phase

connection

Momentary power failure or

voltage drop

Other system communication error

(Slave communication error)

System failure

(EEPROM error)

Optional protection device is

activated. (OP2)

Temperature range warning 1

Temperature range warning 5

JE

1

Inlet oil temperature is higher

than 60˚C.

FH

2

JH

2

J3

2

J5

2

J6

2

L0

2

LC

2

P3

2

P4

2

U0

2

U1

1

U2

2

U9

2

UH

2

UJ

1 or 2

1E

–

Temperature range warning 2

2E

–

Temperature range warning 3

3E

–

Temperature range warning 4

4E

–

5E

–

1) The pump outlet oil temperature thermistor

is disconnected or short-circuited.

Check the wiring of the relevant thermistor.

3) The unit is running under capacity

suppressing control, because the standard

temperature (room temperature: 35˚C, oil

temperature: 35˚C) has been exceeded.

If the standard temperature is exceeded, the cooling capacity

becomes smaller than the nominal capacity, because the unit

runs under capacity suppressing control.

Make sure that the cooling capacity of the Oil Cooling Unit is

larger than the main machine heating value throughout the oper-

ating temperature range.

4) Temperature control is disabled because

the unit is operated in Mode 9 (capacity

direct designation mode).

Select an appropriate operation mode.

(The capacity direct designation mode does not execute temper-

ature feedback control.)

If the exhaust air temperature is almost equal to the room

temperature regardless of the compressor operation, it is possible

that the refrigerant gas has leaked. Contact DAIKIN Contact Center.

Connect a dummy connector to CN8.

Check the wiring of the relevant thermistor.

Check the wiring of the relevant thermistor.

Check the wiring of the relevant thermistor.

Check the wiring of the relevant thermistor.

Repair the refrigerant pipe, and refill refrigerant.

Exchange any phase of the power supply wiring.

Contact DAIKIN Contact Center.

Replace the control board.

Check the preset warning condition.

Check the wiring of the relevant thermistor.

Replace the control board or compressor.

Identify the thermistor that indicates the error in the monitor

mode on the operation panel (“99.9” is displayed), and check

the sensor wiring.

Replace the control board, or improve the power supply

environment. (Take noise suppressing measures.)

Make sure that the L3 phase is properly connected to the

power supply terminal block.

Check the condition detected with the relevant protection device.

Make sure that the power supply voltage conforms to the rating.

Check for instantaneous voltage drop at startup of peripheral equipment.

Make sure that the slave communication line is properly connected.

(This error occurs only when the slave does not make response

in master-slave communication.)

1) The oil temperature thermistor required

for control is disconnected or short-

circuited.

1) The discharge pipe temperature thermistor

is disconnected or short-circuited.

1) The EV valve outlet temperature thermistor

is disconnected or short-circuited.

1) The condenser temperature thermistor is

disconnected or short-circuited.

1) Communication failure between the

temperature control microprocessor and

the inverter microprocessor.

1) The electrical equipment box temperature

thermistor is disconnected or shortcircuited.

1) The radiator fin temperature thermistor is

disconnected or short-circuited.

1) The power supply voltage is lower than

approx. 170 V.

1) An error occurred in communication with

a slave.

1) The parameter stored in the control board

is invalid.

1) The optionally-connected protection device

(or factory-connected device, if it is

incorporated in the unit) has been activated.

1) The monitor temperature has exceeded

the preset temperature. (It does not mean

a fault of the Oil Cooling Unit.)

1) The refrigerant piping is damaged by

excess vibration during transportation,

resulting in refrigerant gas leak.

1) The compressor or inverter has a fault.

1) The power supply is connected in reverse

phase.

2) The L3 phase is open.

5) The refrigerant gas has leaked.

3) The fuse in the control board has blown.

2) For the models without pump outlet oil

temperature thermistor:

Dummy connector is not connected.

PIM00116C_EN.fm 40 ページ 2008年9月29日 月曜日 午前11時51分

Summary of Contents for AKZ8 Series

Page 2: ...PIM00116C_EN fm 0...

Page 43: ...41 PIM00116C_EN fm 41...