S0605050K

Page 22

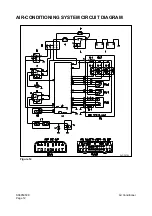

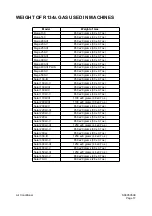

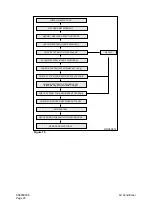

Air Conditioner

Return to Master Table of Contents

2.

Check system for vacuum leak.

Allow system to sit for 10 minutes and

check whether the system is holding the

pressure. If the pressure has dropped, it

must be repaired before proceeding to the

next step.

3.

Vacuuming Procedure.

If the system is holding the pressure and it

has not changed for 10 minutes, vacuum

out the system for an additional 20

minutes.

A.

Turn on the vacuum pump and slowly

open both valves.

B.

Allow vacuum pump to run for additional 20 minutes until the low pressure gauge dial reads

approximately 750 mmHg.

C.

Close both valves and stop the vacuum pump.

4.

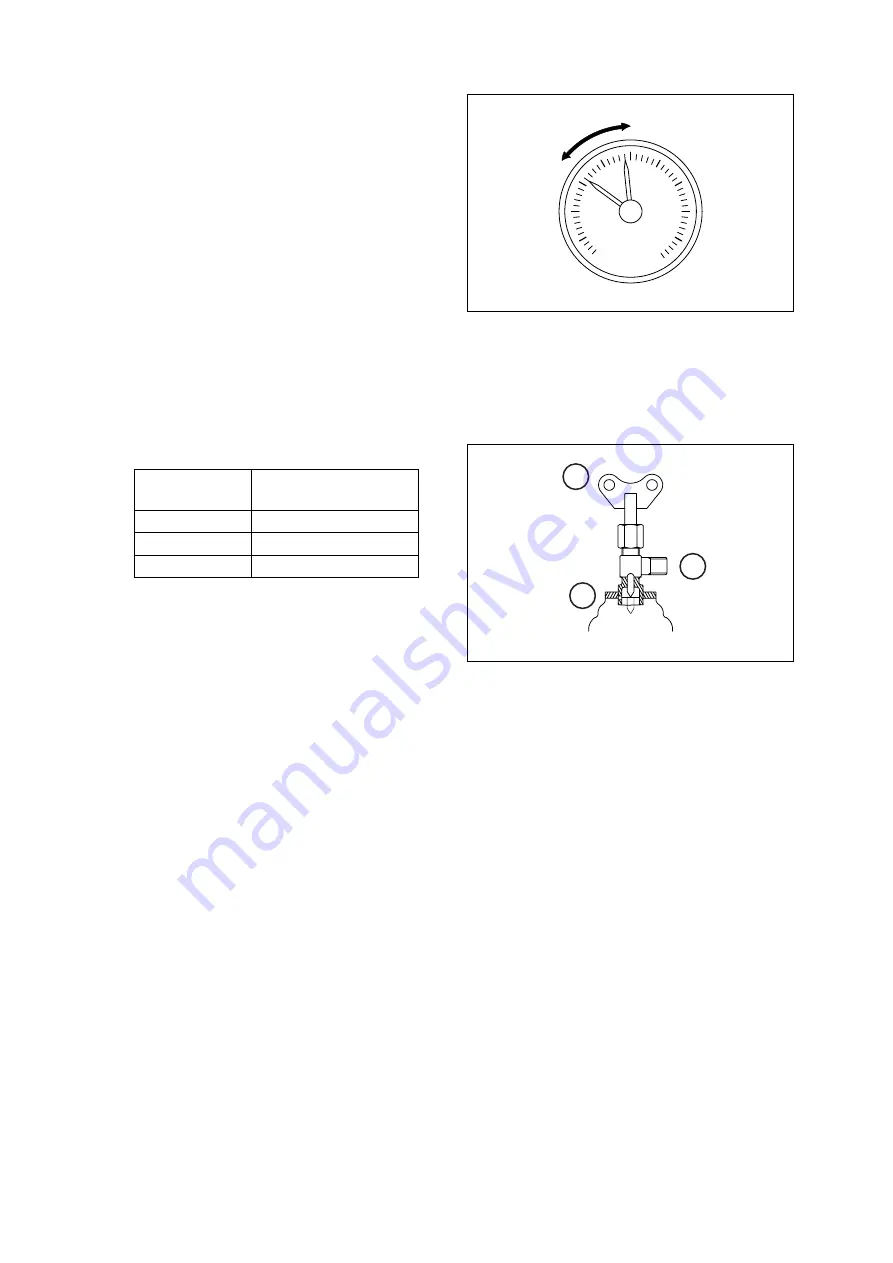

Installation Of Refrigerant Container.

A.

Before mounting valve on the

container, make sure the handle is in

the counterclockwise most position,

with the puncture pin retracted and

the mounting disk is in the raised

position.

B.

Attach the manifold gauge center

hose to the valve assembly.

C.

Turn the disc in the clockwise direction and securely mount valve onto refrigerant container.

D.

Turn the valve handle in the clockwise direction and puncture the container seal with the pin.

E.

Once the can has been punctured, turn the handle in the counter clockwise direction so the

refrigerant can flow into the manifold gauge center hose. At this time, do not open the low and

high pressure valves of the manifold gauge.

F.

Press the manifold gauge low side valve to eliminate the trapped air in the hose.

LEAKAGE CHECK

NOTE:

Perform the leakage check after completing vacuuming process.

1.

After attaching the manifold gauge, open the high side valve.

2.

Charge system until the low side gauge dial indicates a pressure of 1 kg/cm

2

(14 psi) and close the

high side valve.

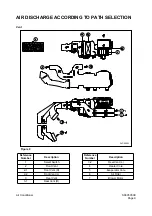

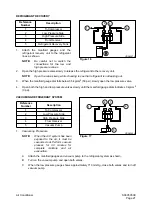

Reference

Number

Description

1

Handle

2

Hose Connection

3

Mounting Disk

HDA6069L

Figure 18

1

2

3

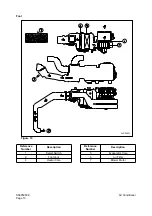

HDA6070L

Figure 19

Summary of Contents for Mega 500-V

Page 4: ...1SAFETY ...

Page 41: ...1SPECIFICATIONS ...

Page 47: ...S0203070K Page 6 Specifications for Mega 500 V ENGINE PERFORMANCE CURVES AHS3720L Figure 2 ...

Page 55: ...S0203070K Page 14 Specifications for Mega 500 V ...

Page 56: ...1GENERAL MAINTENANCE ...

Page 70: ...S0302000 Page 14 General Maintenance Procedures Return to Master Table of Contents ...

Page 83: ...1UPPER STRUCTURE ...

Page 85: ...S0403040K Page 2 Counterweight TABLE OF CONTENTS Specifications 3 Counterweight 3 ...

Page 87: ...S0403040K Page 4 Counterweight ...

Page 98: ...1LOWER STRUCTURE AND CHASSIS ...

Page 104: ...S0502020K Page 6 Center Joint Articulation Joint ...

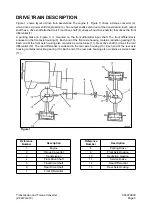

Page 105: ...1ENGINE AND DRIVE TRAIN ...

Page 118: ...S0602170K Page 13 Axle ZF AP 420R Figure 9 ...

Page 119: ...S0602170K Page 14 Axle ZF AP 420R ...

Page 121: ...S0602170K Page 16 Axle ZF AP 420R FINAL DRIVE AP 407 409 Figure 10 ...

Page 123: ...S0602170K Page 18 Axle ZF AP 420R AP 411 415 Figure 11 ...

Page 125: ...S0602170K Page 20 Axle ZF AP 420R AP 417 420 Figure 12 ...

Page 129: ...S0602170K Page 24 Axle ZF AP 420R Differential Carrier RK Figure 14 ...

Page 131: ...S0602170K Page 26 Axle ZF AP 420R Differential Carrier DK ...

Page 135: ...S0602170K Page 30 Axle ZF AP 420R Differential Carrier HK Figure 16 ...

Page 178: ...S0602170K Page 73 Axle ZF AP 420R ILLUSTRATED TABLE Figure 152 ...

Page 194: ...S0602170K Page 89 Axle ZF AP 420R ILLUSTRATED TABLE Figure 196 ...

Page 210: ...S0602170K Page 105 Axle ZF AP 420R ILLUSTRATED TABLE Figure 242 ...

Page 225: ...S0602170K Page 120 Axle ZF AP 420R ILLUSTRATED TABLE Figure 289 ...

Page 251: ...S0605050K Page 26 Air Conditioner Return to Master Table of Contents ...

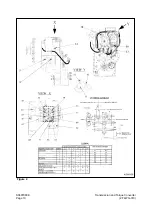

Page 261: ...S0607080K Page 10 Transmission and Torque Converter ZF 4WG 310 Figure 2 ...

Page 264: ...S0607080K Page 13 Transmission and Torque Converter ZF 4WG 310 ...

Page 271: ...S0607080K Page 20 Transmission and Torque Converter ZF 4WG 310 ...

Page 296: ...S0607080K Page 45 Transmission and Torque Converter ZF 4WG 310 ...

Page 447: ...S0607900C Page 36 Transmission Error Codes ZF ...

Page 448: ...1HYDRAULICS ...

Page 478: ...S0705010 Page 22 Cylinders Return to Master Table of Contents ...

Page 489: ...S0708460K Page 11 Main Pump Denison T6DMY Series ...

Page 490: ...S0708460K Page 12 Main Pump Denison T6DMY Series PARTS LIST Figure 8 ...

Page 504: ...S0708460K Page 26 Main Pump Denison T6DMY Series ...

Page 508: ...S0708470K Page 4 Steering and Brake Pump Denison T67DB Series PARTS LIST Figure 2 ...

Page 514: ...S0708470K Page 10 Steering and Brake Pump Denison T67DB Series DISASSEMBLY Figure 5 ...

Page 521: ...S0708470K Page 17 Steering and Brake Pump Denison T67DB Series ...

Page 522: ...S0708470K Page 18 Steering and Brake Pump Denison T67DB Series REASSEMBLY Figure 15 ...

Page 528: ...S0708470K Page 24 Steering and Brake Pump Denison T67DB Series ...

Page 548: ...S0709476K Page 2 Pilot Control Valve Return to Master Table of Contents ...

Page 554: ...S0709476K Page 8 Pilot Control Valve Return to Master Table of Contents ...

Page 557: ...S0709665K Page 3 Flow Amplifier Danfoss GENERAL DESCRIPTION Figure 1 ...

Page 558: ...S0709665K Page 4 Flow Amplifier Danfoss PARTS LIST Figure 2 ...

Page 609: ...S0709730K Page 7 Power Steering Unit Return to Master Table of Contents ...

Page 632: ...S0709730K Page 30 Power Steering Unit Return to Master Table of Contents ...

Page 638: ...S0709750K Page 6 Restriction Valve Return to Master Table of Contents ...

Page 644: ...S0793060K Page 6 Hydraulic Schematic Mega 500 V Return to Master Table of Contents ...

Page 645: ...1ELECTRICAL SYSTEM ...

Page 654: ...S0802190K Page 9 Electrical System Return to Master Table of Contents ...

Page 658: ...S0802190K Page 13 Electrical System Return to Master Table of Contents ...

Page 676: ...S0802190K Page 31 Electrical System Return to Master Table of Contents ...

Page 685: ...S0893060K Page 6 Electrical Schematic Mega 500 V Return to Master Table of Contents ...

Page 686: ...1ATTACHMENTS ...