EN

5) Grounding terminal

The grounding terminal is a special terminal which is used to connect the generator to the ground

properly.

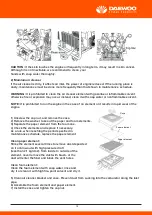

6) Engine protecting system

The engine protecting system is designed to protect engine from damage because of lack of oil in

the crank case. When the engine oil in crank case is lower than the safe level line, the engine protec-

ting system will work to stop the engine automatically (even the engine switch is still in “run” posi-

tion). Thus, the engine may not be worn out because of lack of oil.

5. USE OF GENERATOR

Environmental requirement for use of the generator:

·Serviceable temperature

:

-15

°C~

40

℃

·Serviceable humidity

:

95% below

·Serviceable elevation

:

in area below 1000 m,

(

If using it in the area over 1000 m, the rated power

will degrade.)

1) Connect to power supply

When the generator is taken as a backup power supply to connect with the household appliances,

only the electrician or authorized person can do this job. After connecting the load to the generator,

careful inspection must be performed for reliable connection and safety. It will result in damaging or

burning out the generator or firing because of incorrect connection.

Grounding terminal

Ground

Good

Good

Prohibited

6