www.daewoopower.bg

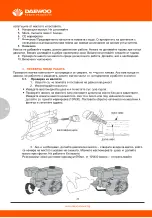

32

BG

No

Part name

Описание

1

Clip tube

Скоба на маркуча за гориво

2

Tube fuel

Маркуч на гориво

3

Joint assy fuel tank

Кранче на резервоара

4

Cap comp fuel filler

Капачка на резервоара

5

Filter fuel

Цедка на резервоара

6

Tank comp fuel

Резервоар

7

Spring throttle return

Възвратна пружина

8

Spring throttle return

Пружина финно регулиране

9

Arm governor

Регулиращо рамо

10

Nut flange

Гайка

11

Pin lock

Фиксиращ щифт

12

Shaft governor arm

Контролен лост

13

Rod goverrnor

Обтяжна щанга

14

Bolt flange

Фиксиращ болт

15

Bolt quadrate head

Фиксиращ болт

16

Control assy

Лостова система на газта

17

Washer pain

Плоска шайба

18

Knob recoil starter

Ръкохватка на стартера

19

Cover comp fan

Капак на стартера

20

Spring recoil satrter

Стартерна пружина

21

Reel recoil starter

Макара на стартера

22

Rope

Въже на стартера

23

Spring return

Възвратна пружина

24

Ratchet starter

Тресчотка на стартера

25

Guide ratchet

Шайба на тресчотката

26

Screw setting

Фиксиращ винт

27

Switch assy engine stop (oil alert) Контактен ключ

28

Cover comp fan

Въздуховод

29

Nut special

Гайка

30

Pulley starter

Стартов фланец

31

Fan cooling

Вентилатор на маховика

32

Flywheel comp

Маховик

33

Diversion assy

Долен капак

34

Oil seal25*41.25*6

Семеринг 25*41.25*6

35

Plate side support

Опорна планка

36

Alart unit oil

Модул на датчика за масло

37

Bolt drain plug

Болт за източване на масло

38

Washer drain plug

Шайба на болта за масло

39

Crank case

Картер

40

Bearing radial ball

Лагер на коляновият вал

41

Oil level switch

Датчик за масло

42

Gear governor

Зъбна предавка на центробежния

регулатор

43

Pin governor weight

Щифт на центробежния

регулатор

44

Shaft governor

Вал на центробежния регулатор

No

Part name

Описание

45

Clip governor holder

Зегерка на центробежния

регулатор

46

Weight governor

Баланс на центробежния

регулатор

47

Washer pain

Плоска шайба

48

Slider governor

Втулков лагер

49

Crankshaft comp

Колянов вал

50

Packing case cover

Гарнитура на капака на картера

51

Oil filler cap

Сонда за маслото

52

Packing oil filler cap

О-пръстен на сондата за масло

53

Cover

Капак на картера

54

Bolt flange

Болт

55

Bolt flange

Болт

56

Nut tool box setting

Гайка

57

Cover air cleaner

Плоска шайба

58

Seal air cleaner

О-пръстен

59

Cover air cleaner

Капак на въздушния филтър

60

Filter outer

Филтърен елемент

61

Nose silencer

Основа на филтърния елемент

62

Elbow comp air cleaner

Основа на въздушния филтър

63

Bolt flange 6*30

Болт м6*30

64

Coil assy ignition

Бобина запалване

65

Pin dower

Фиксиращ щифт

66

Bolt flange 8*55

Болт м8*55

67

Spacer comp air cleaner

Гарнитура на въздушния филтър

68

Lever comp choke

Лост на смукача

69

Carburetor

Карбуратор

70

Packing caburetor

Гарнитура на карбуратора

71

Insulator carburetor

Свързващ блок на карбуратора

72

Packing insul ator

Гарнитура всмукателна

73

Bolt stud in

Шпилка

74

Tube breather

Тръба отдушник

75

Cover comp head

Капак на цилиндровата глава

76

Packing head cover

Гарнитура на капака на

цилиндровата глава

77

Ratator valve

Капачка на клапана

78

Seal guide

Маслообирач

79

Retainer valve spring

Седло на пружуната на клапана

80

Spring valve

Пружина на клапана

81

Plug spark

Запалителна свещ

82

Head comp cylinder

Цилиндрова глава комплект

83

Gasket cylinder

Гарнитура на цилиндровата глава

84

Valve in

Смукателен клапан

85

Valve ex

Изпускателен клапан

86

Lefter valve

Шийка на повдигача

87

Camshaft assy

Разпределителен вал

Summary of Contents for GAET50

Page 18: ...www daewoopower bg 18 BG 3 1 1 1 1 5 2 z z z z z z z z z z z z z z...

Page 20: ...www daewoopower bg 20 BG 5 4 5 6 7 8 9 10 3 3 1 1 2 10W30 3 590 10W30 y y...

Page 21: ...www daewoopower bg 21 BG 3 2 1 2 3 3 1 2 3 3 50 5 4 3 4 1 2 3 4 5...

Page 22: ...www daewoopower bg 22 BG 7 4 4 1 1 2 3 4 4 2 1 2 3...

Page 25: ...www daewoopower bg 25 BG x x 5 3 1 2 3 4 5 5 4 1 2 3 4...

Page 26: ...www daewoopower bg 26 BG 5 5 1 2 3 0 7 0 9 mm 4 5 6 1 OFF 2 3 4 5 ON...

Page 27: ...www daewoopower bg 27 BG 12 5 7 1 2 ON 3 5 8 1 2 8 3 4 5 1 6 2 3 4 5 9...

Page 36: ...www daewoopower bg 36 BG 24 6 6 12 6...

Page 37: ...www daewoopower bg 37 BG 1 1 2022 6 6...

Page 38: ...ZZZ GDHZRRSRZHU EJ...