4

Installation Planning

System Layout

WARNING

To avoid the risk of fire due to the unit overheating:

DO NOT

•

install this blower with a hood or raised

vent that has an internal blower.

DO NOT

•

install more than one blower to increase

the length of the duct run. Even small differences

between blower air flow rates can greatly reduce the

air draw by the hood or raised vent.

Consult the installation instructions for the raised vent

•

or hood for complete layout and duct system plan-

ning instructions. Observe all location and duct system

design instructions.

The remote blower needs to be wired to turn on when

•

the raised vent or hood is turned on by routing wiring/

conduit parallel to the duct work. Connect the wiring/

conduit to the raised vent or hood on one end and the

remote blower on the other. There is a 7/8” electrical

access hole on the bottom of the blower.

Blower Location and Mounting

Install the blower in a location that allows it to be

•

accessed for service if necessary. There must be

enough room to remove the top cover of the unit

and enough room to access the power terminals and

mounting holes located inside.

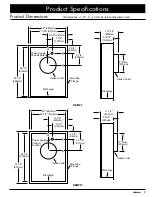

The mounting location needs to allow for a cutout

•

under the unit for the duct and wiring/conduit to pass

through the wall or roof into the blower assembly. See

Figure 1.

The mounting location must allow for a clearance of at

•

least 15” (381mm) between the blower air discharge

and any obstructions (vents, pipes, etc.) See below.

Installation Planning and Preparation

Electrical Supply Requirements

The power for this blower is supplied via 1/2” 3-wire

•

wiring/conduit (not included) by an approved Dacor

hood or raised vent. The wiring/conduit is installed

between the hood or raised vent and the blower and

shall be terminated on each end by a 1/2” UL certi-

fied strain relief. The power is turned on and off by the

power switch on the approved ventilation device.

The correct voltage, frequency and amperage must be

•

supplied to the hood or raised vent and the blower from

a grounded, single phase circuit that is protected by a

properly sized circuit breaker or time-delay fuse. The

circuit must have the capacity to supply the combined

power requirements for the hood or raised vent and the

in-line blower. See the installation instructions for the

hood or raised vent to determine total power require-

ments in combination with the blower electrical specifi-

cations.

Model

Number*

Power

Requirements**

Blower Rating***

REMP3

120 Vac, 60 Hz,

3.8 Amp

600 CFM

REMP16

120 Vac, 60 Hz,

2.7 Amp

1000 CFM

*

All models are thermally protected.

** In addition to the hood or raised vent

*** Nominal rating at 0 inches static pressure. See

Technical Data

section for actual ratings.

The above specifications are for reference only, See the

data label on the blower for exact specifications. If the

above specifications vary from the label on the blower, use

the data on the blower label.

It is the owner’s responsibility to ensure that the power

supply is installed by a licensed electrician. The electri-

cal installation must comply with the latest revision of the

National Electric Code ANSI/NFPA 70 (latest revision) and

local codes and ordinances.

A copy of the specification may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

If the electrical service provided does not meet all product

specifications, or does not conform to the NEC or local

standards, do not proceed with the installation. Call a

licensed electrician to correct the electrical service before

proceeding.

Discharge, no obstructions

within 15 inches

Roof

Wall

Blower

Blower

Duct and wiring passing

through cutout

Example of Roof

Installation

Example of Wall

Installation

Summary of Contents for REMP16

Page 11: ......