6

WARNING

If the electrical service provided does not meet the

•

power requirements for the hood/raised vent and the

blower combined, do not continue with the instal-

lation. Contact a licensed electrician to correct the

situation before continuing.

Failure to connect the wiring as specified may result

•

in an electric shock hazard and/or improper blower

operation.

To avoid the risk of fire or electric shock, turn off

•

power at the circuit breaker panel or fuse box before

connecting the blower to the power source.

The blower assembly is heavy. Do not attempt to lift

•

or move it without assistance.

Parts List

Verify Package Contents

2 1/2” wood mounting screws (8)

•

Blower assembly

•

Parts Required

3 conductor wiring/conduit with UL certified strain relief

•

on each end (length is determined by remote blower

location).

If the blower will be mounted to a surface other than

•

wood, fasteners designed for the material the unit will

be mounted to must be provided. The fasteners must

be capable of supporting the weight of the blower (see

weight table on page 5) and meet local codes and ordi-

nances.

Consult the hood or raised vent installation instructions

•

for additional part requirements.

Installation

Before installing the blower, unpack the unit and check

1.

for physical damage to the motor and blower assembly.

To do so, reach in through the intake collar and spin

the fan blades slowly. They should spin freely and qui-

etly without vibration.

Installation Instructions

Remove the blower’s top cover by removing the screws

2.

around the edge that hold it in place.

Apply sealant between the blower and the mounting

3.

surface where the flange around the edge of the blower

will rest.

Pick up the blower assembly and center it on the

4.

mounting surface inserting the intake collar into the

cutout.

While holding the blower in place, fasten it to the

5.

mounting surface with eight (8) mounting screws. The

mounting holes are located inside the blower assembly

chassis near the sides.

Install the duct work according to the installation

6.

instructions for the hood or raised vent. Support the

duct weight as necessary to ensure properly sealed

joints.

Fan

Blades

Bottom of Blower

Intake

Collar

Figure 5

Figure 6

Sealant

Roof

Air

Discharge

Sealant

Blower

Round Duct

Flange

Figure 7

45° Adjustable

Elbow

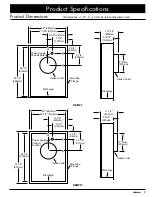

Summary of Contents for REMP16

Page 11: ......