13

External cooling system

OPERATION OF EQUIPMENT

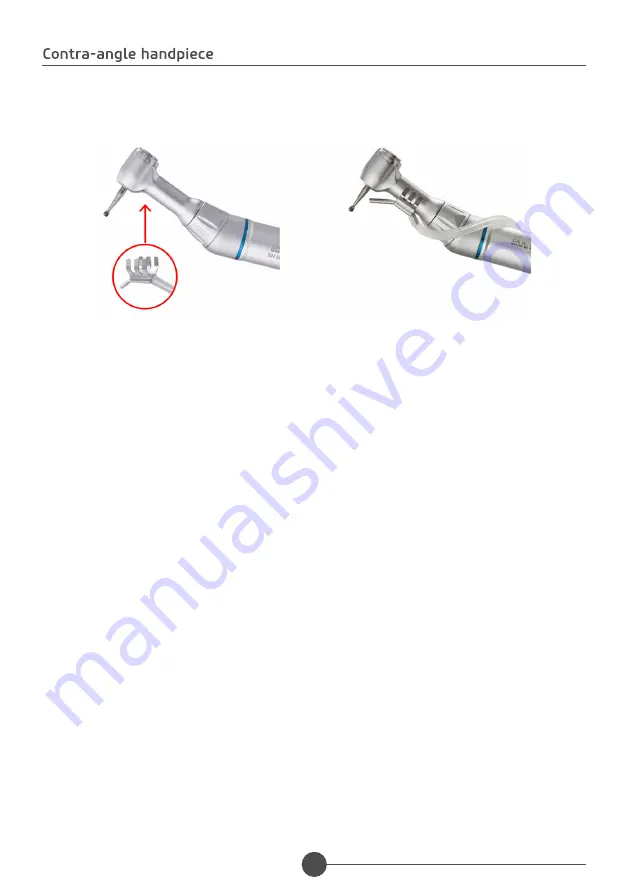

Fit the cooling kit in the Contra-angle handpiece - fig. (a) e (b).

In order to remove it, do the opposite.

fig. a

fig. b

Recommendations for preserving the equipment

Your equipment has been designed and developed according to the standards of modern techology.

Similarly to other kinds of equipment, it requires special care, which is many times neglected due

to several reasons and circunstances. Therefore, here are some important reminders for your daily

routine. Try to follow these simple rules, which will save you a lot of time and will avoid unnecessary

expenses once they start making part of your working procedure.

To prevent the product, check that there is no leakage in the handpiece, according to the method

below:

Attach the handpiece to the appropriate hose, connect it with the activated spray. Check for a leak

in the connection between the handpiece and the coupler.

Transportation, storage and operation

This equipment must be transported and stored observing the following directions:

- Avoid falls and impacts;

- Keep it dry, do not expose it to rain, water drops or wet floor;

- Keep it away from water and direct sunlight, and in it original wrapping;

- Don’t move it over irregular surfaces, protect it from rain and observe the maximum stack quantity

specified in the packaging;

Environmental condition for transportation or storage:

- Room temperature range for transportation or storage -12ºC a +50ºC.

Environmental operation condition:

- Room temperature range for funct10ºC to +40ºC.

- Recommended room temperature range +21ºC to +26ºC.

- Relative humidity range for functioning 30% to 75%.

- Atmospheric pressure range 700 hPa to 1060 hPa (525 mmHg to 795 mmHg).

- Operation altitude: ≤2000m.

PRECAUTIONS, RESTRICTIONS AND WARNINGS