CPS-B1

CPS-B1

99.828.32 1.4/07/21

99.828.32 1.4/07/21

18/

24

19/

24

English

English

Once a year by a specialist company, who is

authorized by the appliance manufacturer.

Renew test badge, keep log book.

The respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies have been

specially trained by D+H for carrying out expertly

this maintenance, and they get automatically the

latest maintenance instructions.

Maintenance

Following tests must be carried out in the course of

maintenance:

- Outside examination / inspection of system

components

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according to

directions

Inspection

Regular visual inspection between maintenance by the operator or a trained person.

Immediately correct any defects.

Indicators:

-

Green LEDs

in the buttons must

illuminate

.

-

Yellow LEDs

in the buttons and the control panel

are

not allowed to illuminate or flash

(fault).

- If the green LEDs do not illuminate or if the

yellow LEDs illuminate or flash, contact After

Sales service.

Examination:

- Check all appliances and cable connections for

outer damage and dirt accumulation.

- Fire detectors, smoke vent buttons, smoke vents

and so on must not be impaired in their function

by goods in storage or structural changings.

Inspection and maintenance has to be carried out

according to D+H maintenance notes. Only original

D+H spare parts may be used. Repair is to be

carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Repair and cleaning

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

Disposal

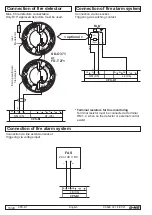

Informations for starting

Carry out following sight and performance checks for switching-on the smoke and heat vent

control panel.

All cables

connected?

Factory set?

(DIP switch)

10k

Ω resistor in

smoke vent

button

?

End module

2x47k

Ω

in junction box?

Connect mains.

LED mains lightens?

Connect battery

lines. Control l

ightens?

Smoke vent

flap opens and

closes?

All necessary moving loads connected?

Smoke vent components are line-monitored.

A malfunction is connected as alarm in delivery condition of

control panel. The smoke vent opens self-acting and can be

reset under special conditions only.

yes

yes

yes

yes

yes

yes

yes

Performance check alarm/reset and ventilation

yes

Partial or incomplete connection of

components can cause malfunction.

Check following connections: mains 230 V,

drives, smoke vent buttons, when necessary

fire detectors and vent buttons.

See wiring an connection plans pages 14-15.

Delivery condition of DIP switch see page 10.

Resistor must be cramped in electric last

button on terminal 3/8 (RT 45).

See connection plan pages 14-15.

Resistor must be cramped in last or only fire

detector on terminal 3 and 5 (type SD-O/FD-T).

Resistor remains in control panel between

terminal RM "R" and "–", when no fire

detector is connected.

See connection plan page 16.

10k

Ω resistor in fire

detector?

yes

End module on last or only drive in junction

box on wire „E“ orange, „a“ black, „b“ black.

See connection plan page 14.

Check line safety fuse in distribution box and

fuse mains in control panel.

Mains still not available or line switch on "0"

or one of fuses faulty.

Possibly change poles in drive.

no

no

no

no

no

no

no

no