9

The front hitch assembly is required to mount the snow blower on

the tractor. If the front hitch is installed it has to be removed for

proper installation.

Remove the front hitch as follows:

Disconnect the hitch hydraulic hoses from the hydraulic

8.

outlets of the tractor. Install the protective caps on the hitch

hoses, and remove the hoses from hose support rods. Install

the protective plugs in the hydraulic outlets.

Remove the hex cap screws and hex lock nuts securing the

9.

hitch mounting brackets to the tractor frame, and carefully

lower the hitch assembly from the tractor.

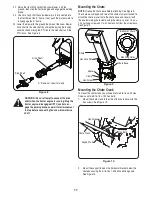

Connect the stub shaft to the backside of the ‘A’ frame

10.

bracket as shown in Figure 2. Mount the stub shaft using

the hex screws and hex lock nuts shown in Figure 2. When

mounting the stub shaft be sure that the grease fitting is

facing downward.

Re-install the front hitch with the stub shaft in place.

11.

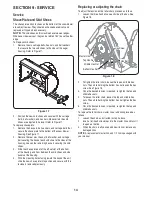

Mount the drive shaft the stub shaft as shown in Figure 3.

12.

section 6: unpacking

Unpacking the Snow Blower

Move the tractor and snow blower to a firm flat area large enough

to accommodate both. Allow enough room to install the snow

blower on the front of the tractor.

Carefully open the shipping container. Cut any ties or bands

•

securing the snow blower, chute assembly, drive shaft, chute

crank and front hitch PTO to the shipping pallet. Remove the

snowblower, chute assembly, drive shaft, chute crank and

front hitch PTO from the shipping container.

Remove the hardware from the manual bag. Check that the

•

parts in the manual bag and the parts that came attached to

the crate are correct by referring to Figure 1 and the list on

page 3.

section 7: installation

Installing the Snow Blower

If your front hitch is equipped with the angle kit, the hitch angle

cylinders will need to be replaced. Follow the instructions below to

replace the cylinders.

WARNING! Do not disconnect hydraulic lines until

all system pressure is relieved. Lower the

attachment to ground, stop engine, and operate

all hydraulic control levers

Disconnect the angle kit hoses from the tractor hydraulic

1.

couplers, and slide the hoses out of the protective sleeve.

From either side of the tractor, remove the hex lock nuts, hex

2.

screws, washers, and spacers securing the cylinder to the

hitch ‘A’ frame and mounting bracket. Reassembly and Insert

the hardware in the appropriate cylinder ends and loosely

fasten with the hex lock nut to store the cylinder assembly.

Move to the other side the tractor and repeat the above step

3.

to remove the cylinder on that side of the tractor.

Remove the cotter pins and clevis pins from the fixed length

4.

hitch arms.

From either side of the tractor, align the shorter hub of the

5.

hitch arm with mounting bracket at the bottom of the hitch

bracket, and insert the shorter clevis pin. Secure with the

cotter pin.

Raise the longer hub end of the hitch arm up between the

6.

mounting brackets on the bottom of the ‘A’ frame. Insert the

longer clevis pin and secure with the cotter pin.

Move to the other side of the tractor and repeat the previous

7.

two steps to install the fixed length hitch arm on that side of

the tractor.

Stub Shaft

Hex Screw

Hex Lock Nut

figure 2

Stub Shaft

Drive Shaft

figure 3

Summary of Contents for 59A40051727

Page 17: ...17 Notes page ...