Hand Operated Machines and Cutting Speed:

The blade is rotating at approximately 3700 RPM. When moving the blade through the material, the blade must

NEVER

be allowed to

dwell in the work. If fine finishes are required:

1. Use a sharp blade.

Do Not Force the Cutting Action,

causing the motor to stall.

2. Use a

constant, even pressure

when cutting through material.

Spring Return:

Each sawhead is equipped with a drawbar return spring. The function of the spring is to return the sawhead to the

rest position upon release of the handle.

Do not adjust the spring pressure.

If the spring breaks,

Replace It

Immediately!

Make sure spring is attached properly (see Diagram “D” on Page No. 8) and

Never use a hand

operated machine without the return spring in place.

Clamping and Work Slippage:

The work must never be allowed to move or vibrate as it is being cut. When the work is positioned against a stop,

it

must be clamped

either by hand holding or by pneumatic air clamps.

Never allow unclamped work between

the blade and the stop, as the blade can grab the material and throw it, thereby causing damage to the

blade, the machine, and possibly harming the operator.

CTD offers both Horizontal and Vertical Clamps. The Horizontal Clamp pushes the material backwards against the

rear fence and is mounted in the keyways of the base. A Vertical Clamp holds the material down, against the table base, and

is mounted through and on top of the fence bracket. Both clamps are offered as optional extras and are highly recommended.

If you purchased your machine with an Air Downfeed of the saw, the clamps are actuated prior to activating saw head by

depressing the Foot Valve. An Anti-Tie Down, Two Hand Control drives down the sawhead. If clamps are purchased using

a hand operated machine, then the clamps will move into position by pulling the saw head down slightly. This releases the

Automatic Valve (AV) to supply air to the clamps.

Be careful not to overtighten clamp cylinder bracket

on the

cylinder. This will cause irregular function of the cylinder.

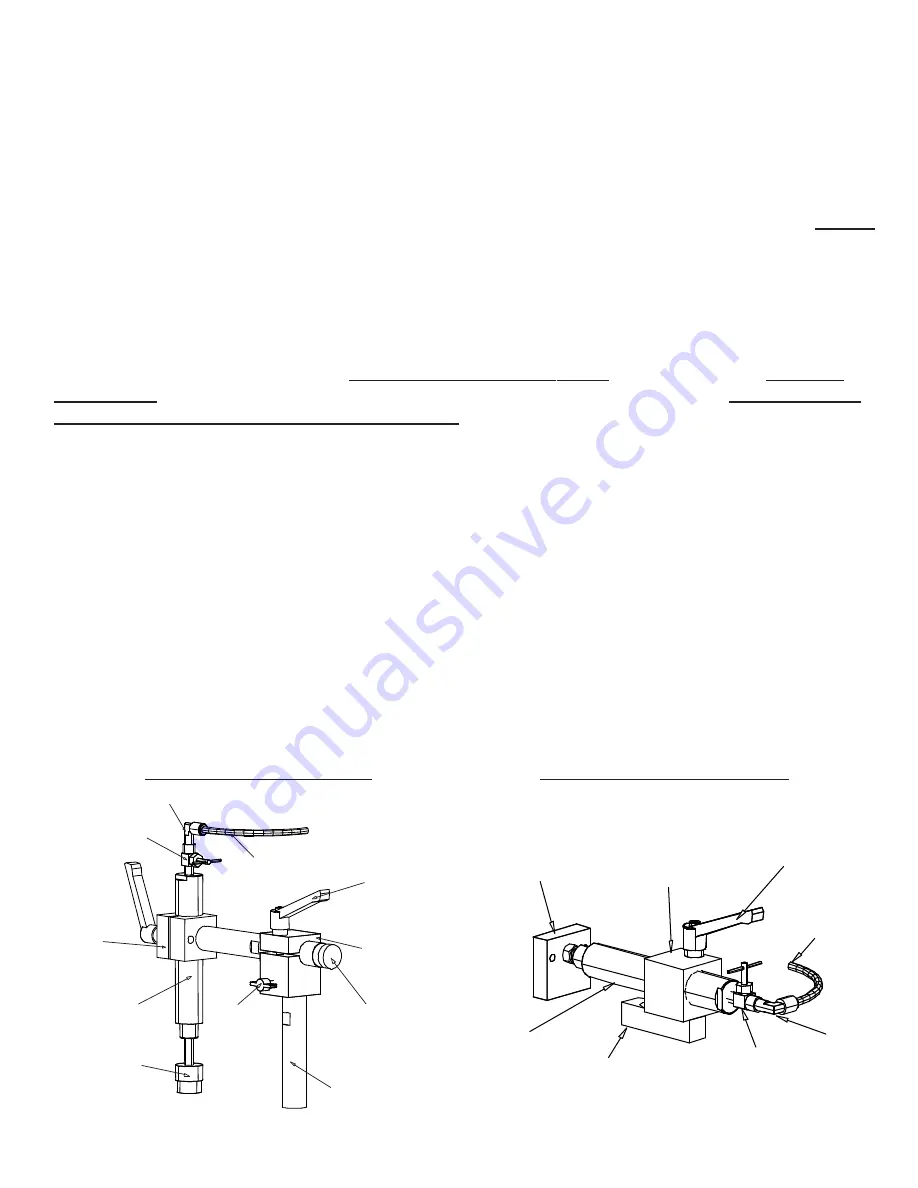

200R Vertical Clamp Assembly

200R Horizontal Clamp Assembly

-9-

1/4” elbow fitting

B3P61

shut off

valve

200M22

vert. cyl.

brkt.

2B3P20

3” stroke

air cyl.

2B3P20C

vert. clamp

pad

200BIP22

wing nut

VC

1/4” red polyflo line

200B7P19

adjustable

lock handle

200M21

vert. clamp

adjustment

brkt.

200M20B

horiz. bar adj.

for vert. clamp

200M20C

vert. clamp

support bar

2BM28

horiz. clamp

pad

200B3P21

3” stroke

air cyl.

200M27

horiz. clamp

key

B3P61

shut off

valve

1/4” elbow fitting

1/4” red polyflo line

200B7P19

adjustable

lock handle

200M22

vert. cyl.

brkt.

4. Turn mitre locking handle to center position, and the spring loaded pin & handle will automatically engage into

preset angle settings. The preset angle settings are 45

°

, 30

°

, 22 ½

°

, 15

°

, 0

°

on both sides of the centerline or zero

point.

Do not let the spring loaded mitre locking pin & handle engage in several degree settings as

you rotate the mitre base disc. This will cause excess wear on preset angle settings.

5. For all angles that are not preset, follow instructions under #1 to lock handle in the open position.

Simply align degree quadrant on disc with zero mark on base and tighten down intermediate mitre lock handle

located in base.

Summary of Contents for CM325R

Page 8: ...WiringDiagrams...

Page 9: ......

Page 21: ...19 LEFT OPPOSITE 200 SERIES RIGHT SAW ASSEMBLY...

Page 23: ...21 200 Series Right Blade Guard Assy Left Opposite REAR VIEW...

Page 26: ...24 Air Feed System Exploded View...

Page 27: ...25 CM325R Left Saw Assembly Right Opposite...

Page 29: ...27 CM325R Left Base Assy Right Opposite...

Page 30: ...M25HC Base Assembly Exploded View 28...

Page 31: ...200HC Series Blade Guard Assembly 29...

Page 33: ...Notes...