Vortex FP Compact Installation & Operation Manual

3

Issue 1, January 2013

1. INTRODUCTION

1.1 S

AFETY

I

NFORMATION

Vortex FP Compact is a certified Flameproof (Exd) detector suitable for use in ATEX Zone 1

or Zone 2 hazardous areas.

x

Vortex FP Compact must be installed, operated and maintained in strict accordance

with these instructions, warnings, label information, and within the limitations stated.

x

The cover retaining bolts must be kept tightly closed until power to the control system

is isolated - otherwise ignition of a flammable atmosphere can occur.

x

Before removing the cover for maintenance or calibration purposes, ensure the

surrounding atmosphere is free of flammable gases or vapours.

x

Maintenance and calibration operations must only be performed by qualified service

personnel.

x

Only genuine Crowcon replacement parts must be used; substitute components may

invalidate the certification and warranty of the system.

x

Vortex FP Compact must be protected from extreme vibration.

x

Vortex FP Compact must be protected from direct sunlight in hot environments as

this may cause the temperature of the system to rise above its specified limits and

cause premature failure.

x

Vortex FP Compact is supplied certified for use in hazardous areas only with the

components originally fitted. No other devices may be fitted within the Vortex FP

Compact enclosure.

1.2 P

RODUCT

D

ESCRIPTION

Vortex FP Compact is a sophisticated control system designed for monitoring up to twelve

gas detectors. Three input channels may alternatively be used for monitoring conventional

smoke or heat detectors, or flame detectors. Vortex FP Compact may contain (depending on

specification) up to 16 relays for control of external devices.

Vortex FP Compact is supplied in an Exd Flameproof junction box constructed of LM25

aluminium and finished with a tough polyester coating. Gas levels, alarms and faults can be

viewed through the window, and system functions can be accessed either via the push-

buttons or by using the supplied ‘Crowmag’ magnetic key.

Vortex FP Compact may be delivered configured for 1-4, 1-8 or 1-12 input channels, and

with up to two 8-way relay modules (one relay module only if three input modules are fitted).

If intrinsically safe (I.S.) field devices are to be connected, the required Zener barriers or

galvanic isolators must be located within a separate Exd certified enclosure. Alternatively a

larger version of the product: Vortex FP is available with space sufficient for such devices.

Please refer to the specification sheet provided with the system for exact configuration

details.

Vortex FP Compact is based on Crowcon’s Vortex control system, and the standard Vortex

manual (part number M07211) must be referred to in conjunction with these instructions.

Vortex FP Compact is not available with back-up batteries fitted. For continued operation in

the event of mains supply failure, it is recommended that Vortex FP Compact is connected to

a suitable UPS system.

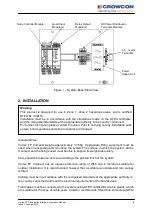

A view of internal system modules and components is shown on the following page.