3

A - GENERAL INFORMATION

TO THE PURCHASER:

Congratulations! You are the owner of one of the fi nest

pumps on the market today. These pumps are products

engineered and manufactured of high quality components.

With years of pump building experience along with a

continuing quality assurance program combine to produce

a pump which will stand up to the toughest applications.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

RECEIVING:

Upon receiving the pump, it should be inspected for

damage or shortages. If damage has occurred, fi le a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

STORAGE:

Short Term -

Pumps are manufactured for effi cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term -

Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained b40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

SERVICE CENTERS:

For the location of the nearest Deming Service Center,

check your Deming representative or Crane Pumps &

Systems Service Department in Piqua, Ohio, telephone

(937) 778-8947 or Crane Pumps & Systems Canada, Inc.,

Bramton, Ontario, (905) 457-6223.

B - BEFORE YOU BEGIN

Motor driven pumps are carefully aligned on sub-base

before shipment. However, after they are placed upon the

foundation and sub-base is bolted down, the alignment

must be rechecked and in MOST CASES it will be found

necessary to carefully realign the unit. Quite often a noisy

pump is due to pump and motor not being properly aligned.

IN SUCH CASES WE DISCLAIM ALL RESPONSIBILITY

FOR PROPER WORKING OF PUMP.

Pumps are normally furnished with standard stuffi ng box

construction as shown on page 5. Flushing type stuffi ng box,

or mechanical shaft seal on pages 5 and 6 can be furnished

in lieu of standard stuffi ng box.

The single shaft seal on page 5 is used for handling clear

liquids at temperatures below their boiling point or 212°F

(100°C) as recommended by the seal manufacturer. A

portion of this liquid is by-passed into the seal chamber

through the by-pass tube (127) to serve as a lubricant and

as a coolant. The by-pass from the pump discharge must be

minimum of 20 pounds pressure above the suction pressure

of the pump to insure proper operation of the seal.

The double shaft seal on page 6 is used when pumping

abrasive or non-lubricating liquids or liquids of excessive

temperature. If the discharge pressure ever exceeds 25

pounds, a sealing liquid at 15 to 20 pounds higher than

maximum discharge pressure must be circulated through

the seal chamber. Clear water under such pressure can be

used in most applications as a sealing liquid for lubrication

and cooling.

If the discharge pressure is constantly under 25 pounds and

the temperature is less than the boiling point of the liquid

being pumped or 212°F (100°C), then seal chamber can be

fi lled with a quality light weight ball bearing grease. A spring-

loaded compression type grease cup should be installed to

maintain pressure in the seal chamber.

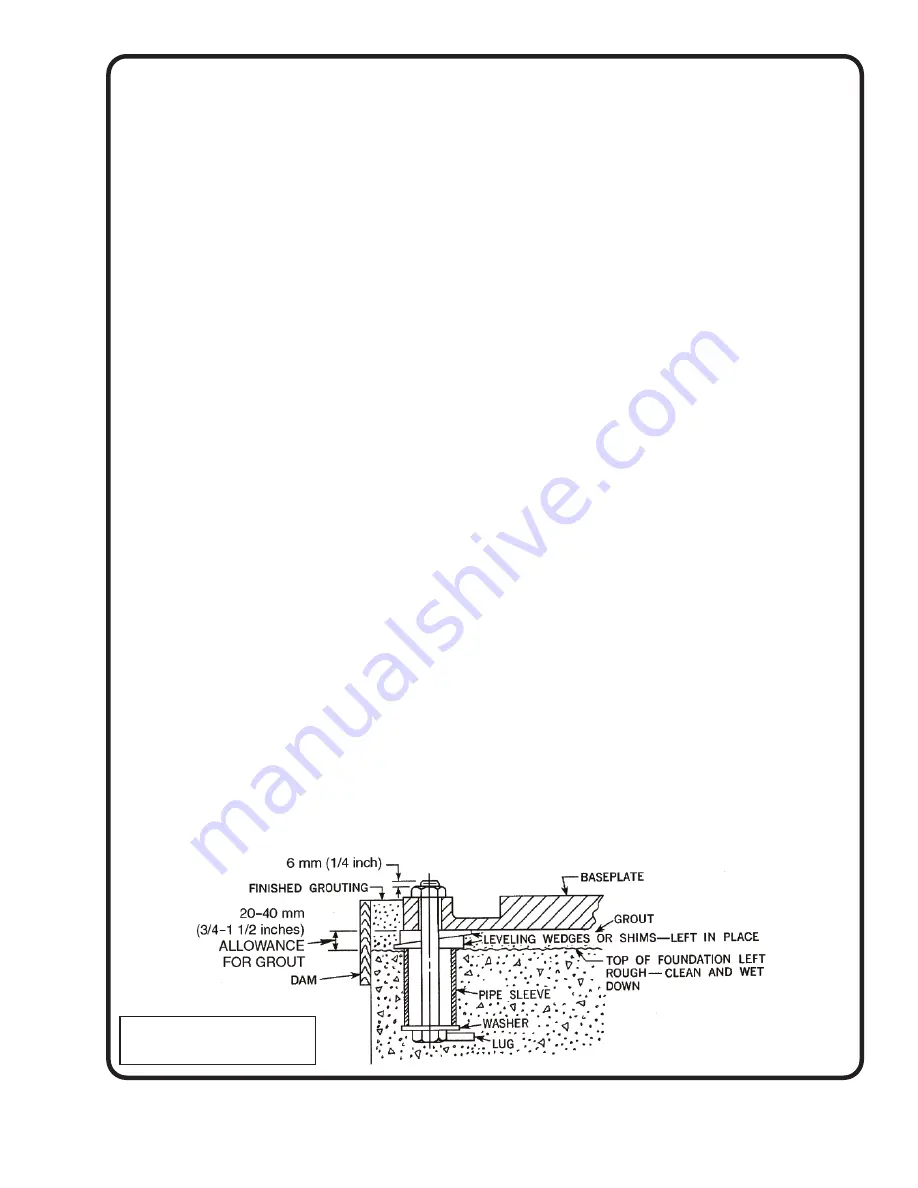

C - INSTALLATION

1. A good rigid foundation must be provided for pump

base.

2. Place pumping unit on foundation with bolts, of the

proper size, imbedded in the concrete. A pipe sleeve,

about 2½” diameters larger than the bolt, should be

used to allow for fi nal positioning of the bolts. See

Figure 1.

Figure 1. Foundation Bolt

Location and Anchorage