5

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER

GRADE

Sohio / Standard

SE 40, Energol HL22 or HL32

Shell

Turbo Oil 32

Texaco

Rando HD32, 522

Sun Petroleum

Supar 110, Sunvis 816WR, 911 or 916

Mobile

D.T.E. Oil Light or Rubrex 200

G&G

Circu Oil 22

Allegheny Petroleum

Altrapar 22

Woco

Premium 100

Caution! - Pressure builds up extremely

fast, increase pressure by “tapping” air

nozzle. Too much pressure will damage

seal. Do Not exceed 10 P.S.I. in motor

housing.

2) Impeller and Volute Service:

2.1) Disassembly and Inspection:

To clean out volute, disconnect power, remove hex nuts and

lockwashers, vertically lift motor and seal assembly from

volute. Clean out body if necessary. Clean and examine

impeller for pitting or wear, replace if required. Inspect square

ring and replace if cut or damaged. If impeller requires

replacing, remove jam nut and washer, by placing a fl at

screwdriver in the slot of the end of the shaft to hold the shaft

stationary while unscrewing the impeller. Once impeller is

removed, remove pull washer and exclusion seal if damaged

or cut.

2.2) Reassembly:

Position exclusion seal on shaft until it seats against the

stationary portion of seal. Place pull washer on shaft until it

seats against exclusion seal. To install impeller, apply a thin

fi lm of oil to motor shaft and slide impeller straight onto shaft,

keeping keyways lined up, drive key into keyway. Locate

washer, apply Loctite to shaft threads, thread hex nut to shaft

and torque to 40 ft. lbs. Rotate impeller to check for binding.

Position o-ring on volute fl ange and position impeller and

motor housing assembly over studs and onto volute. Apply

thread locking compound to each stud. Thread nut onto studs

and torque to 20 ft. lbs. Check for free rotation of motor and

impeller.

3) Motor, Bearing and Seal Service

3.1) Disassembly and Inspection:

To examine or replace the motor, bearing and shaft seal,

disassemble volute and impeller as outlined in paragraph 2.1.

Drain oil from motor as outlined in paragraph 1.2.

Position unit upright, using blocks to avoid resting unit on

shaft. After removal of cord motor housing remove cable

lead wires from motor lead wires and temperature sensor

wires (if equipped) from sensor cord, by disconnecting wire

connectors. Also disconnect ground screw from motor.

The wiring connections should be noted to insure correct

connections when reassembling.

Motor -

Remove the motor bolts and lift motor stator from

motor rotor and seal plate. Unscrew conduit bushing from

seal plate and lift motor rotor, shaft, bearing, rotating portion

of seal, washer and conduit bushing from seal plate.

Inspect windings for shorts and check resistance values.

Check rotor for wear, if rotor or the stator windings are

defective, the complete motor must be replaced. To test

the temperature sensor (if equipped), check the continuity

between the black and white wires. If found to be defective

contact a motor service station or Barnes Service

Department. Check motor capacitor on single phase units

and replace if defective.

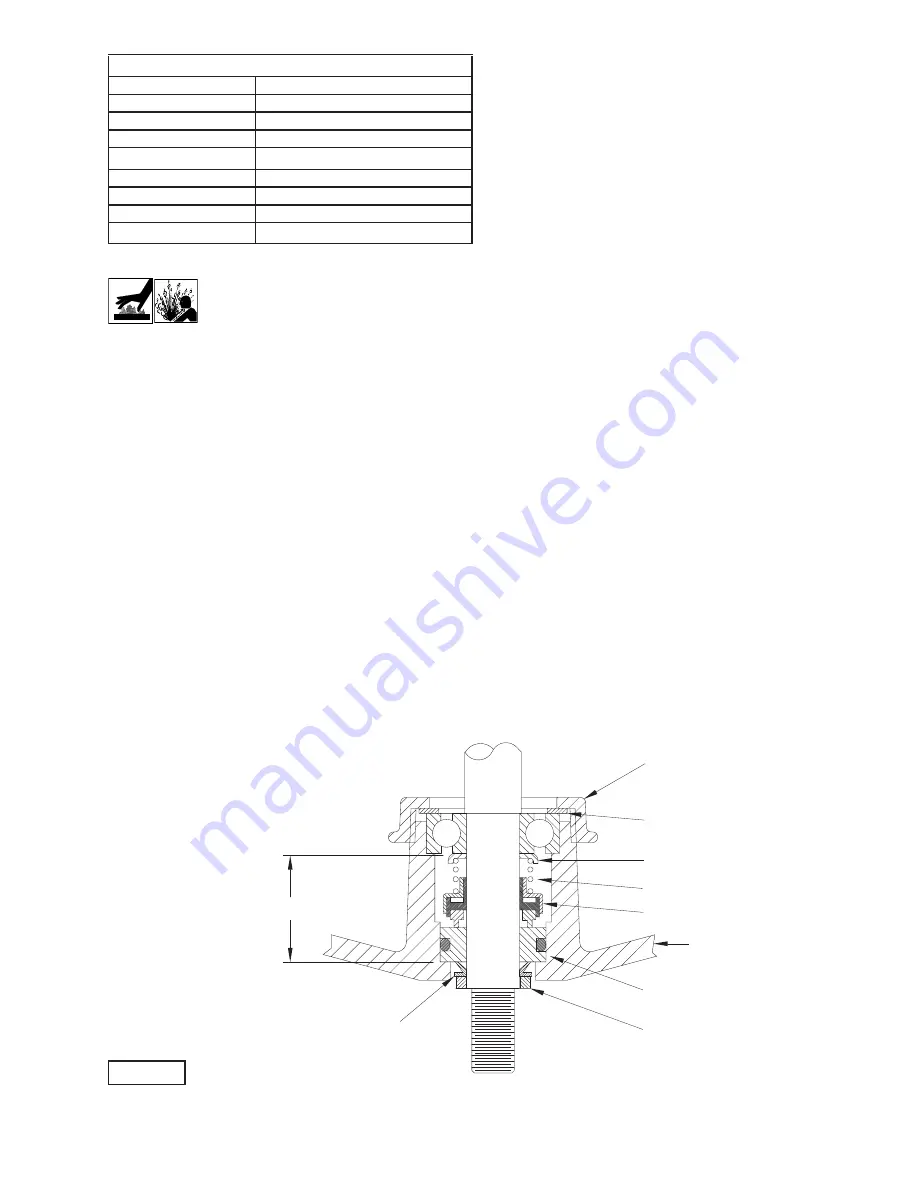

FIGURE 2

SEAL ASSEMBLY

RETAINING RING

SEAL PLATE

SPRING

ROTATING MEMBER

STATIONARY

CONDUIT BUSHING

WASHER

PULL WASHER

EXCLUSION SEAL

MOTOR END

(INBOARD END)

PUMP END

(OUTBOARD END)