5

English

OPERATION

WARNING:

To reduce the risk of serious personal

injury, read, understand and follow all safety

warnings and instructions prior to using tool.

WARNING: It is important to support the work

properly and to hold the drill firmly with both

hands to prevent loss of control which could

cause personal injury.

WARNING: Do not attempt to tighten drill bits (or

any other accessory) by gripping the front part of

the chuck and turning the tool on.

Damage to the

chuck and personal injury may occur when

changing accessories.

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can cause injury.

WARNING: To reduce the risk of injury, let the

tool work at its own pace.

Do not overload.

Proper Hand Position (Fig. D)

WARNING:

To reduce the risk of serious personal

injury,

ALWAYS

use proper hand position as shown.

WARNING:

To reduce the risk of serious personal

injury,

ALWAYS

hold securely in anticipation of a

sudden reaction.

WARNING:

Drill may stall (if overloaded or improperly

used) causing a twist. Always expect the stall. Grip

the drill firmly with both hands to control the twisting

action and prevent loss of control which could cause

personal injury. If a stall does occur, release the trigger

immediately and determine the reason for the stall

before re-starting.

Proper hand position requires one hand on the handle

6

.

and the other bracing the body of the drill to control the

twisting action.

Fig. D

6

Variable Speed Trigger Switch (Fig. E)

To turn the tool on, squeeze the variable speed trigger

1

.

To turn the tool off, release the trigger switch. The variable

speed switch enables you to select the best speed for a

particular application. The more you squeeze the trigger,

the faster the tool will operate. Use lower speeds for starting

holes without a center punch, drilling in metals or plastics,

or driving screws. For maximum tool life, use variable speed

only for starting holes or fasteners.

nOTE:

Continuous use in variable speed range is not

recommended. It may damage the switch and should

be avoided.

WARNING:

The drill should only be locked ON

when it is held stationary in a drill press stand

or other means;

NOT BY HAND! Never unplug the

tool with the locking feature engaged. To do so will

cause the tool to start immediately the next time it is

plugged in.

Selecting the Direction of Rotation (Fig. E)

For drilling and for tightening screws, use forward

(clockwise) rotation. For loosening screws or removing a

jammed drill bit, use reverse (counterclockwise) rotation.

nOTE:

The direction of rotation is also depicted by an arrow

on the overmold of the tool near the forward/reverse

lever

3

.

Never change the direction of rotation while the motor

is running.

1. To select forward rotation, push the forward/reverse

lever to the right (when viewed from the chuck end).

2. To select reverse rotation, push the forward/reverse

lever to the left (when viewed from the chuck end).

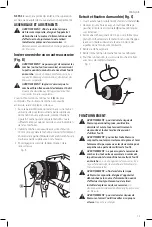

Removing and Attaching the Chuck

(Fig. C)

1. Open the keyless chuck

4

as far as possible.

2. Remove the keyless chuck retaining screw

7

, located

in the keyless chuck, by turning it clockwise using a

screwdriver (lefthand thread).

3. Tighten a hex wrench of 1/4" or greater size (not

supplied) into the keyless chuck and strike it with a soft

hammer in a counterclockwise direction as shown.

4. Remove the hex wrench.

5. Remove the keyless chuck by turning

it counterclockwise.

6. To attach the keyless chuck, screw it onto the spindle

and secure it with the keyless chuck retaining screw.

Fig. C

4

7

Summary of Contents for CMED731

Page 30: ......

Page 31: ......

Page 32: ...CRAFTSMAN 701 East Joppa Road Towson MD 21286 Copyright 2018 08 18 Part No N638219 ...