English

6

Accessories

WARNING:

Since accessories, other than those

offered by CRAFTSMAN,

have not been tested with

this product, use of such accessories with this tool

could be hazardous. To reduce the risk of injury, only

CRAFTSMAN recommended accessories should be

used with this product.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. If you need assistance in locating any

accessory, please contact CRAFTSMAN, call

1-888-331-4569

.

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can cause injury.

Fig. E

3

1

Drilling

• Always unplug the drill when attaching or removing

accessories. When attaching accessories in the keyless

drill chuck, it is important to securely tighten the chuck

to prevent slippage. When using a keyless chuck, hand

tighten firmly.

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the

General Power Tool Safety Warnings

.

• Use appropriate and required safety equipment, as

instructed in the

General Power Tool Safety Warnings

.

• Secure and maintain work area, as instructed in the

General Power Tool Safety Warnings

.

• Run the drill very slowly, using light pressure, until the

hole is started enough to keep the drill bit from slipping

out of it.

• Apply pressure in a straight line with the bit. Use

enough pressure to keep the bit biting but not so much

as to stall the motor or deflect the bit.

• Hold the drill firmly with both hands to control its

twisting action.

• Drills equipped with a side handle must use the

side handle.

• DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF

AND ON IN AN ATTEMPT TO START IT. DAMAGE TO THE

DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure

and slowly drilling through the last part of the hole.

• Keep the motor running while pulling the bit out of a

drilled hole. This will help reduce jamming.

Drilling In Wood

Holes in wood can be made with the same twist drill bits

used for metal or with spade bits. These bits should be

sharp and should be pulled out frequently when drilling to

clear chips from the flutes.

Drilling In Metal

Use a cutting lubricant when drilling metals. The exceptions

are cast iron and brass which should be drilled dry. The

cutting lubricants that work best are sulfurized cutting oil

or lard oil.

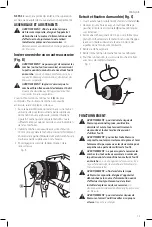

Versatrack™ (Fig. F)

WARNING:

To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can cause injury.

WARNING:

To reduce the risk of serious personal

injury, do not use a damaged Versatrack™ peg hook

or Versatrack™ Trackwall. A damaged Versatrack™

peg hook or Versatrack™ Trackwall will not support

the weight of the tool.

WARNING:

To reduce the risk of serious personal

injury, DO NOT suspend tool overhead or suspend

objects from the peg hook. ONLY suspend tool on the

Versatrack™ Trackwall using the peg hook.

WARNING:

Ensure that the tool weight does not

exceed the maximum rated weight for the selected

Versatrack™ hook.

WARNING:

When hanging objects on a Versatrack™

Trackwall rail, adequately space the tools in order to

not exceed 75 lb (35 kg) per linear foot.

iMPORTAnT:

Versatrack™ accessories mount compatible

tools securely to the Versatrack™ Trackwall system.

1. Turn tool off, disconnect it from power source and

remove accessories.

CAUTION:

Any product with exposed cutting teeth

must have them covered securely if it is to be on

the Versatrack™ Trackwall.

2. Mount the peg hook

8

to the Versatrack™ Trackwall.

3. Slide the tool loop

9

onto the peg hook on the tool.

nOTE:

Versatrack™ accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. If you need assistance in locating any

accessory, please contact CRAFTSMAN, call

1-888-331-4569

.

Drilling in Masonry

Use carbide tipped masonry bits. Keep even force on the

drill but not so much that you crack the brittle material. A

smooth, even flow of dust indicates the proper drilling rate.

Versatrack Variables

1ST_Figure

1ST_Callout

2ND_Callout

F

8

9

Summary of Contents for CMED731

Page 30: ......

Page 31: ......

Page 32: ...CRAFTSMAN 701 East Joppa Road Towson MD 21286 Copyright 2018 08 18 Part No N638219 ...