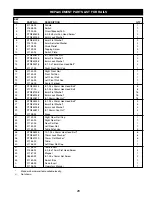

Rip Fence Dimensions:

Rip fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1

⁄

4

″

Rip fence rails (front and rear) . . . . . . . . . . . . . . . . . . . . . 56

1

⁄

2

″

Blade capacity maximum . . . . . . . . . . . . . . . . . . . . . . . . . . 10

″

Blade arbor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

⁄

8

″

Dado blade capacity maximum . . . . . . . . . . . . . . . . . . . . .

13

⁄

16

″

Saw Constructions:

Cabinet . . . . . . . . . . . . . . . . . . . . Totally enclosed steel panel

Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cast iron

Rip fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum tube

Drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V-belt

Exhaust port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

″

Male

Miter gauge . . . . . . . . . . . . . . Cast iron with T-slot roller guide

Blade guard . . . . . . . . . . . . . . Acrylic with anti-kickback pawls

Switch. . . . . . . . . . . . . . . Locking paddle switch with overload

Arbor R.P.M.. . . . . . . . . . . . . . . . . . . . . . . . 3450 RPM approx.

Motor: . . . . . . . . . . . . . . . . . 1

3

⁄

4

HP, 3550 RPM, capacitor start,

capacitor run, 120/240V, 15/7.5A,

single-phase, ball bearing

Gross weight with motor . . . . . . . . . . . . . . . . . . . . . . . 288 lbs

WARNING:

Disconnect power before attempting any of the

following procedures. Be certain switch is in OFF position and

safety disconnect (or breaker) is in OFF or open position. Saw

blade must not be moving. Saw blade will rotate freely after

motor is turned off. Allow blade to come to a complete stop

before attempting any of the following procedures.

WARNING:

The operation of any power tool can result in

foreign objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with United States ANSI Z87.1 before commencing power tool

operation.

STARTING AND STOPPING THE SAW

Refer to Figure 43.

WARNING:

Never operate saw without blade guards in

place. Be sure blade is not in contact with workpiece when

motor is started. Start motor and allow saw to come to full

speed.

WARNING:

Make sure the electrical characteristics of motor

nameplate and power source are the same.

• The ON/OFF switch is located under the front rail of the

table saw at the left side.

• To turn saw on, stand to either side of the blade—never in

line with it. Raise large red OFF paddle and pull up

ON/OFF switch. Always allow saw blade to come up to full

speed before cutting.

• Do not turn motor switch ON and OFF rapidly. This action

overheats the motor and may cause saw blade to loosen.

• Never leave saw while the power is on.

• To turn the table saw off, press the large red OFF paddle.

Never leave saw until cutting tool has come to a complete

stop.

The saw can be locked from unauthorized use by locking the

switch. To lock the switch:

• Turn the switch to OFF position and disconnect saw from

power source.

• Pull the key out. The switch cannot be turned on with the

key removed.

NOTE:

Should the key be removed from the switch at the ON

position, the switch can be turned off but cannot be turned on

again.

• To replace key, slide key into the slot on switch until it

snaps.

WARNING:

For your own safety, lower blade or cutting tool

below table surface. If blade is tilted, return it to vertical posi-

tion. Turn off safety disconnect or circuit breaker when saw is

not in use.

BLADE HEIGHT ADJUSTMENT

Refer to Figure 44.

• Blade height is controlled by handwheel on the front of the

saw.

• To adjust height, loosen locking hand knob. Rotate knob

counterclockwise approximately three turns. Turn hand-

wheel to desired blade height.

CAUTION:

For safety, blade should be raised only

1

/

8

″

above

the surface of the material to be cut. However, if hollow

ground blades are used, raise blade to its maximum height to

allow for greater blade clearance.

• Lock blade height into position. Lock handwheel by tight-

ening locking knob clockwise. Tighten only until snug.

IMPORTANT:

Do not over tighten. Only a small amount of

pressure is necessary to lock handwheel securely.

BLADE TILT ADJUSTMENT

Refer to Figures 44 and 45, page 15 and 16.

• The saw blade can be set at any angle between 90° and

45°. Blade tilt is controlled by the handwheel (Fig. 44) on

the right side of the saw. The indicator (Fig. 45) on front of

saw shows the tilt angle of the blade.

• To adjust tilt, loosen locking hand knob. Rotate knob coun-

terclockwise at least three turns. Turn handwheel to

desired blade angle. Lock blade angle into position.

15

Figure 43 - ON/OFF Switch

Paddle

Switch

Key

Figure 44 - Blade Height Adjustment

Angle

Indicator

Lock Knob

Handwheel