19

WORK-PIECE INSPECTION

Before cutting the work-piece, make sure to

inspect it for nails, staples, small pieces of

stone or metal and any other object which

is dangerous to come on contact with the

blade.

If the wood contains any of these objects

and it comes in contact with the blade, the

object might fly and hit the operator or

seriously damage the blade. For a safe

cutting method always inspect your work-

piece carefully before cutting and wear eye

protection.

Some woods with excessive twisting or

wrapping are un-stable while cutting. This

situation can be dangerous, because during

operation the work-piece can move un-

expectedly which can either damage the

blade or hurt the operator.

If the wood is slightly cupped, make sure

the cupped face of the wood is held against

the table or the fence. If the bowed side of

the work-piece is held against the table or

the fence, there will be a great possibility

that the work-piece move unexpectedly

while cutting, and cause kickback or injury

to the operator.

Some stock with large knots can damage

the blade and wet stock will give a poor

result.

OPERATIONS

Before doing the operation, make sure all

the parts of the machine are assembled

properly and you have done the test run.

Make sure you have read the manual and

you are familiar using the table saw,

knowing all the safety features on this

machine.

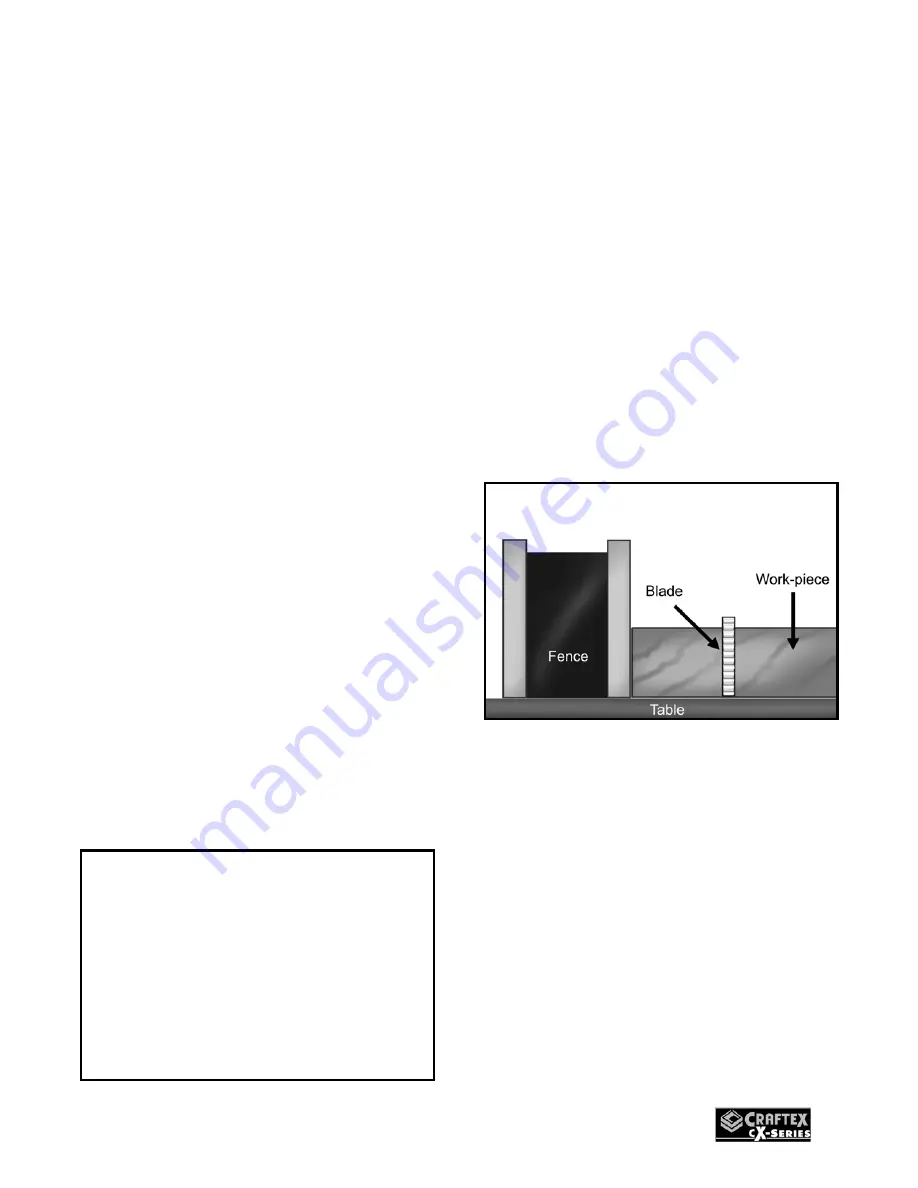

THROUGH CUTS

The operation, in which the saw blade cuts

the work-piece completely, is called through

cut. Ripping, cross cuts, miter cuts and

beveled cuts are examples of through cuts.

Figure-30 Shows an example of through cut

For clarity the blade guard assembly is not

shown in figure-30 but for your safety it is

highly recommended to use blade guard

when performing through cuts.

NON-THROUGH CUT

The operation, in which the work-piece is

passed over the saw blade and it does not

cut the work-piece all the way through its

thickness, is called non-through cut.

WARNING

The information above is just a guideline

for you to understand how to cut a work-

piece with slight cupping. If you are not

sure and do not have any experience in

cutting cupped stock, do not cut it.

Failure to follow these instructions might

bring personal injuries to the operator or

serious damage to the blade.

Summary of Contents for CX series

Page 1: ...CX200 10 CX201 10 HEAVY DUTY TABLE SAW WITH RIVING KNIFE User Manual ...

Page 25: ...25 CX200 CX201 BODY PARTS BREAKDOWN ...

Page 27: ...27 CX200 CX201 TRUNION ASSEMBLY PARTS BREAKDOWN ...

Page 30: ...30 CX200 CX201 BLADE GAURD PARTS BREAKDOWN ...

Page 34: ...34 CX200 30 RAILS EXTENSION TABLE PARTS BREAKDOWN ...

Page 36: ...36 CX201 50 RAILS EXTENSION TABLE PARTS BREAKDOWN ...