21

with the blade and the blade is cutting the

waste side of the line.

Connect the cord to the power source and

turn the table saw “ON”. Let the blade to

reach its full speed and hold the work-piece

against the face of the miter gauge. Slowly

push the work-piece with the miter gauge

and until it is completely past the blade. Let

the blade come to a complete stop and

remove the cut-off work-pieces.

Figure-33 Crosscutting operation

MITER CUTS

Miter cut is an angled crosscut performed in

the same manner as crosscut, using miter

gauge.

Place the face of the miter gauge against

the edge of the work-piece and miter gauge

bar across the face of the work-piece. Use

the bar as a guide and mark the angle of

cut with a pencil as shown in figure-34.

Place the miter gauge back into the T-slot

and hold the work-piece against the face of

the miter gauge. Push the work-piece with

the miter gauge slowly against the blade

until the work-piece is completely past the

blade.

Figure-34 Marking the angle of cut

BEVEL CUTS

The CX200/CX201 blade can be tilted to

the left between 0° and 45° by rotating the

blade tilt hand wheel. This feature of the

saw allows making bevel cuts.

To make bevel cuts, rotate the blade tilt

hand wheel to the desired angle, looking at

the tilt scale and lock the hand wheel by

tightening the lock at the center of the hand

wheel.

After that, proceed to make the cut in the

same manner as in “Cross Cutting”. See

page-20.

For more accurate cuts angles,

use a digital angle finder.

Model# B2646

Model# WR300

Summary of Contents for CX series

Page 1: ...CX200 10 CX201 10 HEAVY DUTY TABLE SAW WITH RIVING KNIFE User Manual ...

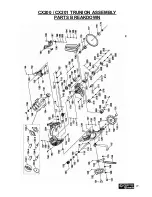

Page 25: ...25 CX200 CX201 BODY PARTS BREAKDOWN ...

Page 27: ...27 CX200 CX201 TRUNION ASSEMBLY PARTS BREAKDOWN ...

Page 30: ...30 CX200 CX201 BLADE GAURD PARTS BREAKDOWN ...

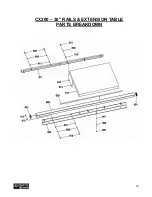

Page 34: ...34 CX200 30 RAILS EXTENSION TABLE PARTS BREAKDOWN ...

Page 36: ...36 CX201 50 RAILS EXTENSION TABLE PARTS BREAKDOWN ...