− 11 −

Operating Procedure

3. Operating Procedure (continued from previous page)

■

Functions and Setting Methods

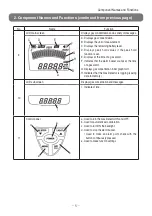

Press the MENU switch for approximately three seconds on the gas concentration screen. The

buzzer will beep once, followed by two beeps after a short pause, and the following settings can be

made and executed.

The following settings and execution can be reset by turning OFF the Gas Detector.

Item

Function

Reference

page

1. Peak hold function

Continues displaying the peak value of the detected

gas concentration. (Lower limit peak value)

P. 12

2. Alarm buzzer silencing

The gas alarm buzzer will not sound when the

detected gas concentration reaches the alarm level.

P. 13

3. Detectable gas selection

XP-3180 and XP-3180E cannot be set.

4. LCD selection

XP-3180 and XP-3180E cannot be set.

5. Execution and completion of

logging

Logs (saves in memory) the detected gas

concentration and date. To read the data, a PC (see

page 1 for the required conditions) and Log Data

Collection Set (optional item) are required.

P. 14

6. Data logger communication

Reads logged data. A PC (see page 1 for the required

conditions) and Log Data Collection Set (optional item)

are required.

P. 15

7. Time settings

Makes date, month, year, and time settings.

P. 16

Peak hold setting screen

Buzzer silence setting screen

Detectable gas setting screen

LCD selection screen

(This detector can not be set.)

Time setting screen

Data logger

communication screen

Press

SYMBOL.

Press

SYMBOL.

Logging execution screen

Initial menu screen

Summary of Contents for XP-3180

Page 30: ...MEMO...

Page 31: ......